Movable cleaning device for burr of rectangular continuous casting slab

A cleaning device and continuous casting billet technology, which is applied in the field of steelmaking and continuous casting billet production equipment, can solve the problems of inability to install, increase the difficulty of transformation, and occupy a large space for installation of equipment and facilities, so as to reduce costs, eliminate scarring, Eliminates the effect of reducing the ability to blow off cutting dross

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

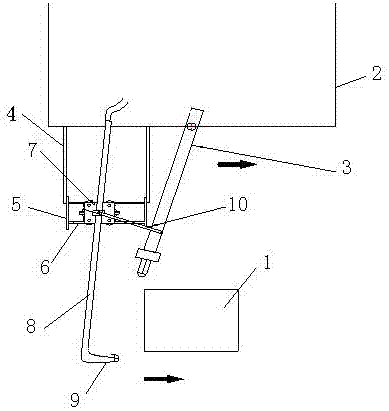

[0020] The invention uses compressed gas to blow and separate unsolidified cutting slag at the bottom of the cutting seam of the cutting slab during the flame cutting process of the continuous casting slab, so as to remove and improve the burrs generated in the continuous casting slab cutting process. At the same time, the invention uses a moving device to enable the gas nozzle to have the function of synchronous operation with the cutting torch running track of the continuous casting machine, which eliminates the problem of reduced ability to blow off cutting slag caused by the increased distance between the gas nozzle and the cutting point during the cutting process.

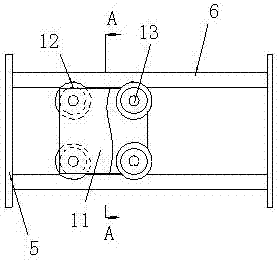

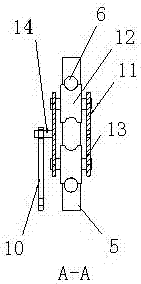

[0021] The present invention is made up of fixed rod 4, fixed frame 5, slide rail 6, slide block 7, gas nozzle 8, gas nozzle 9, connecting rod 10.

[0022] figure 1 It shows that the fixed frame 5 is fixedly connected with the continuous casting slab cutting trolley 2 through the fixed rod 5, the fixed frame 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com