Intelligent high-speed laser cutting machine control system

A laser cutting machine and control system technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low processing efficiency and low control precision, and achieve fast processing speed, simple adjustment and control operation, and precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

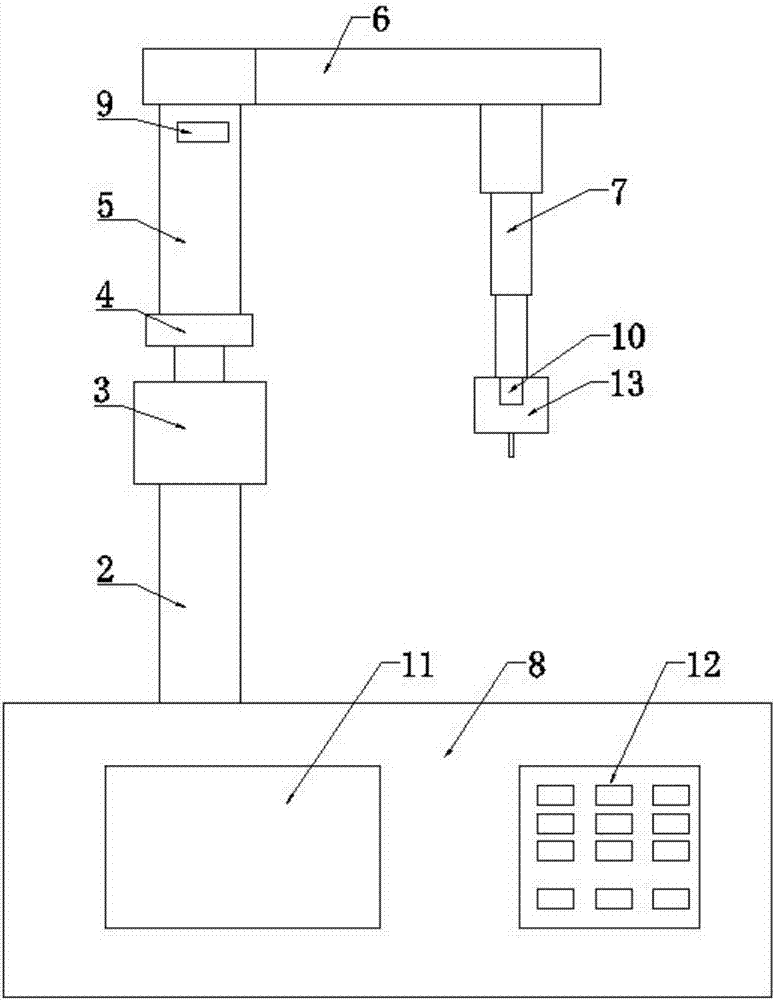

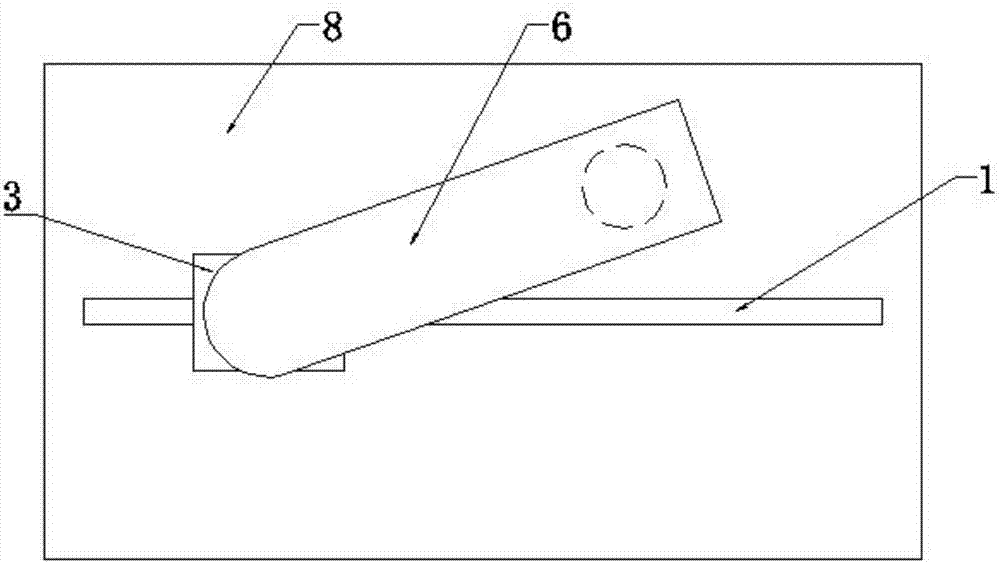

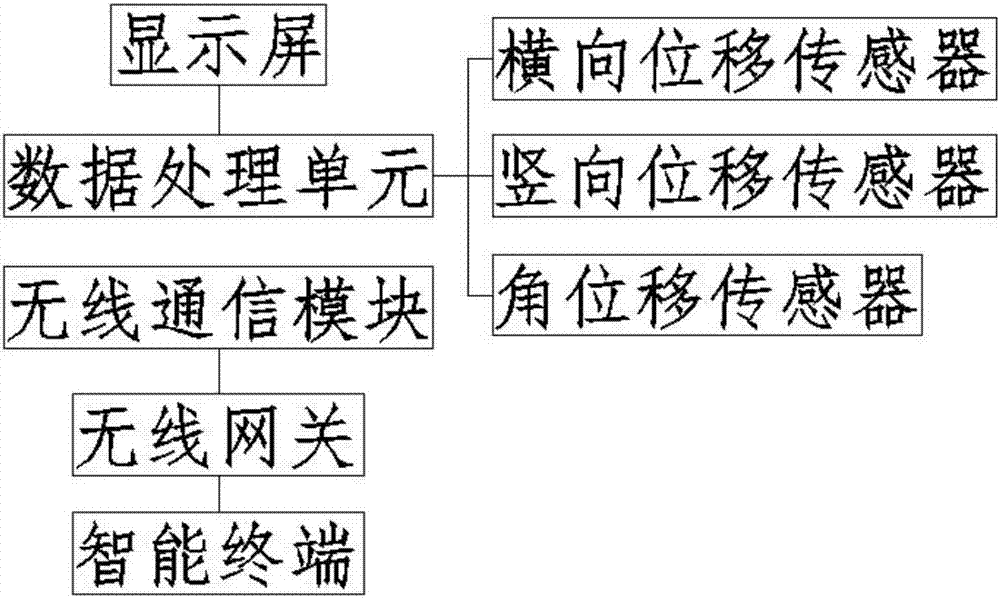

[0025] An intelligent high-speed laser cutting machine control system in this embodiment includes a cutting machine base 8 and a laser cutting machine 13, an X-axis chute 1 is arranged on the upper surface of the cutting machine base 8, and a support column 2 is arranged above the cutting machine base 8 The lower end of the support column 2 is slid in the X-axis chute 1 through the electric slider, and the upper end of the support column 2 is provided with a rotating motor 3; Rod 6; the power end of the electric telescopic rod 7 is arranged on the lower surface of one end of the cross rod 6, and a laser cutting machine 13 is arranged at the telescopic end of the lower end of the electric telescopic rod 7; , a vertical displacement sensor 10 is set on the laser cutting machine 13; a display screen 11 and a key control area 12 are set on the front surface of the cutting machine base 8, and the keys in the key control area 12 are electrically connected to the electric slider, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com