Automatic book thread stitching system

A technology of moving system and transmission system, which is applied in the direction of bookbinding, etc. It can solve the problems of manual production errors in production efficiency, difficulty in ensuring the quality of thread-bound books, and easy rusting of metal nails, so as to improve efficiency, stable and reliable gap operation, and support stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

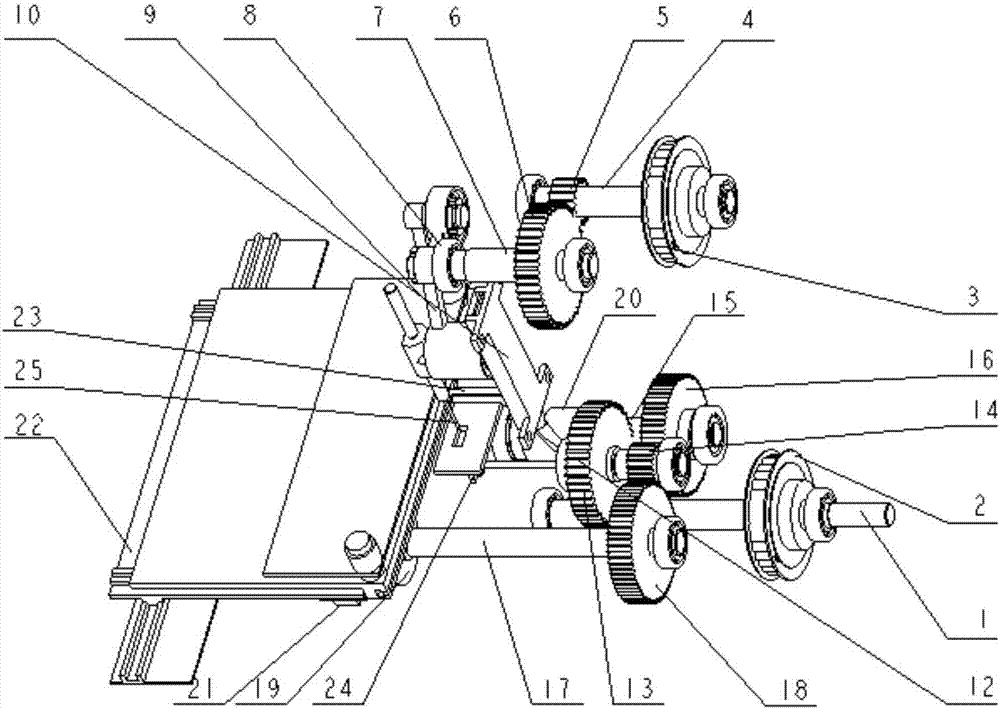

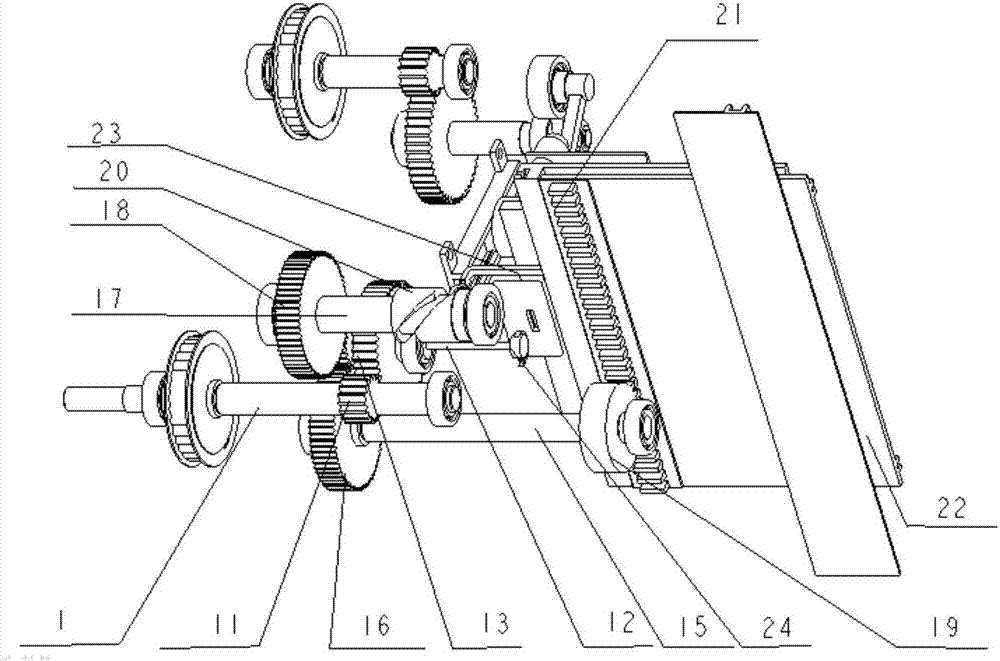

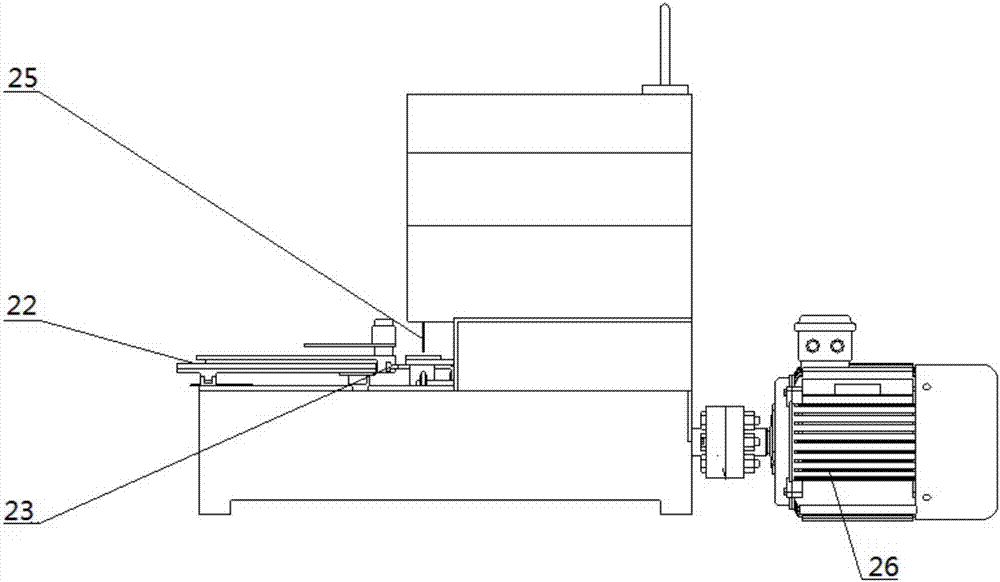

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

[0023] like figure 1 As shown, the book automatic thread loading system includes a mobile platform, a machine needle system, a coil sewing system, a book moving system and a transmission system. and the rotary hook shaft, the motor is connected to the drive shaft through a coupling, the drive shaft is provided with a synchronous pulley a and a gear c, the shaft a is provided with a synchronous pulley b and a gear a, and the synchronous pulley a and the synchronous belt The wheel b is connected by a synchronous belt, and the shaft b is provided with a gear f and a missing tooth gear, and the missing tooth gear meshes with the rack of the mobile platform. The push rod is connected, the crank shaft is provided with gear b and the needle system, the hook shaft is provided with gear d, gear e and the hook, gear d meshes with gear c, gear e meshes with gear f and gear g at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com