Vertical takeoff and landing fixed wing unmanned aerial vehicle with variable pitch propellers

A vertical take-off and landing, propeller technology, applied in the direction of vertical take-off and landing aircraft, unmanned aircraft, landing gear, etc., can solve the problems of poor maneuverability, low flight speed, and the inability to meet the rapid flight of drones, etc., to achieve reduction Dependence on the runway of the venue and the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with embodiment.

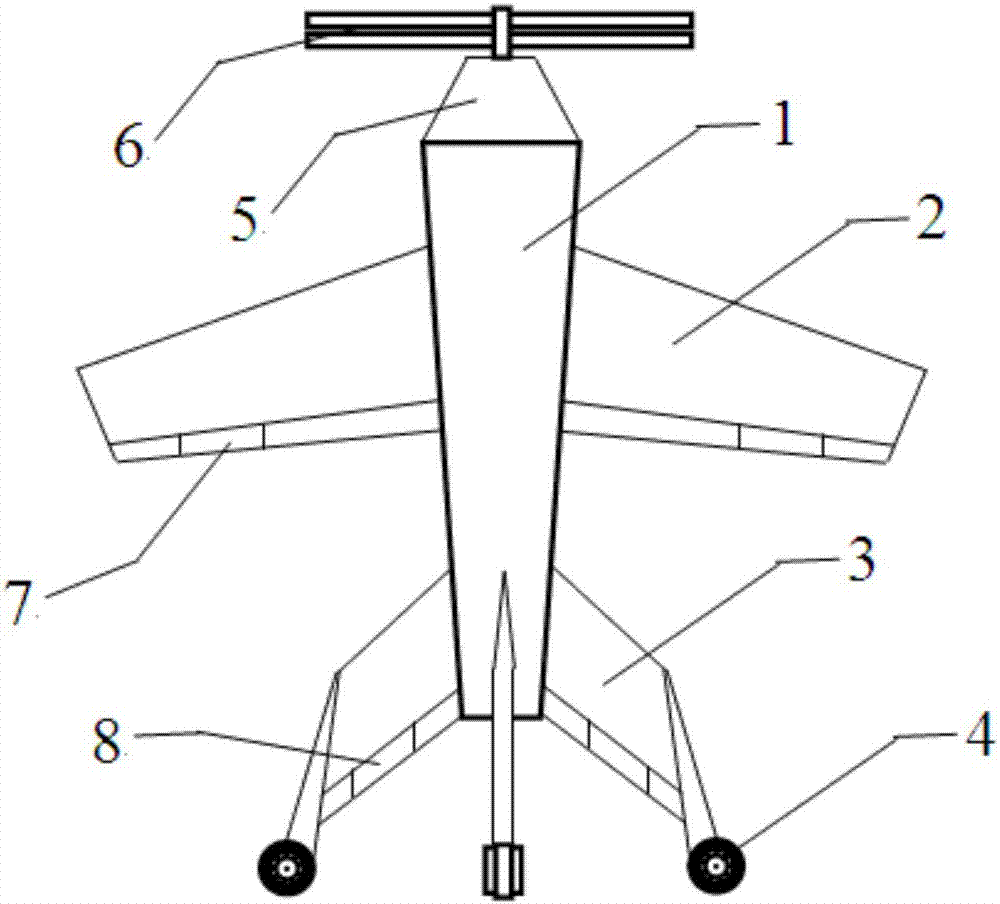

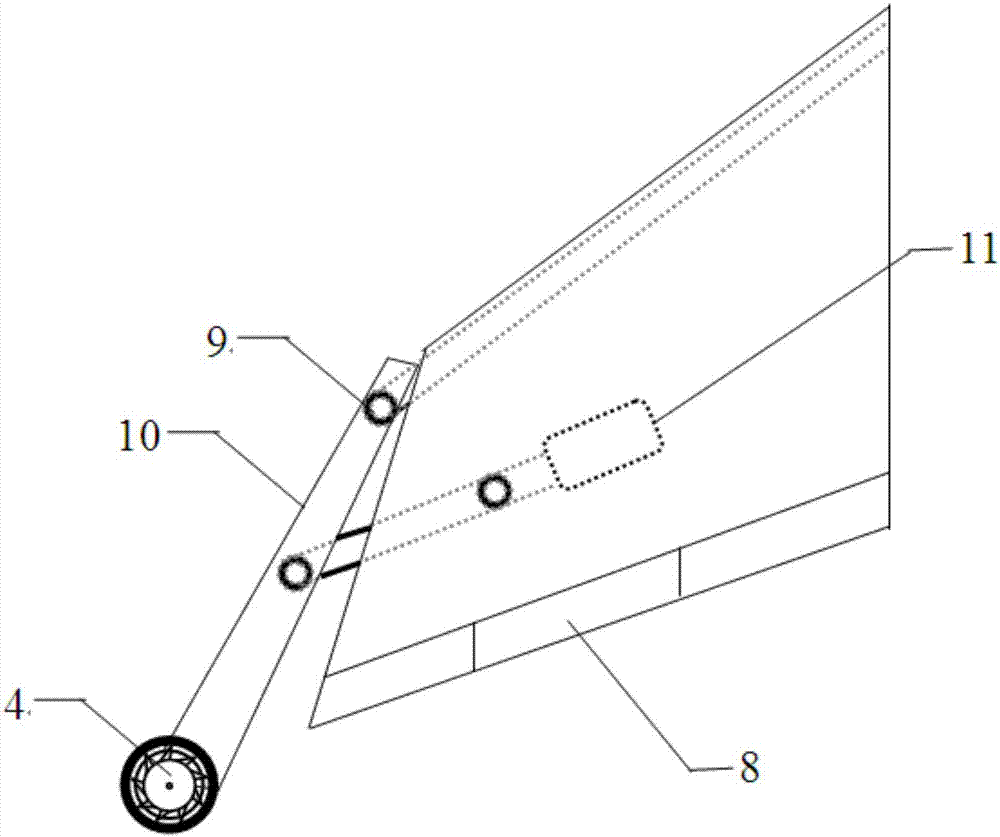

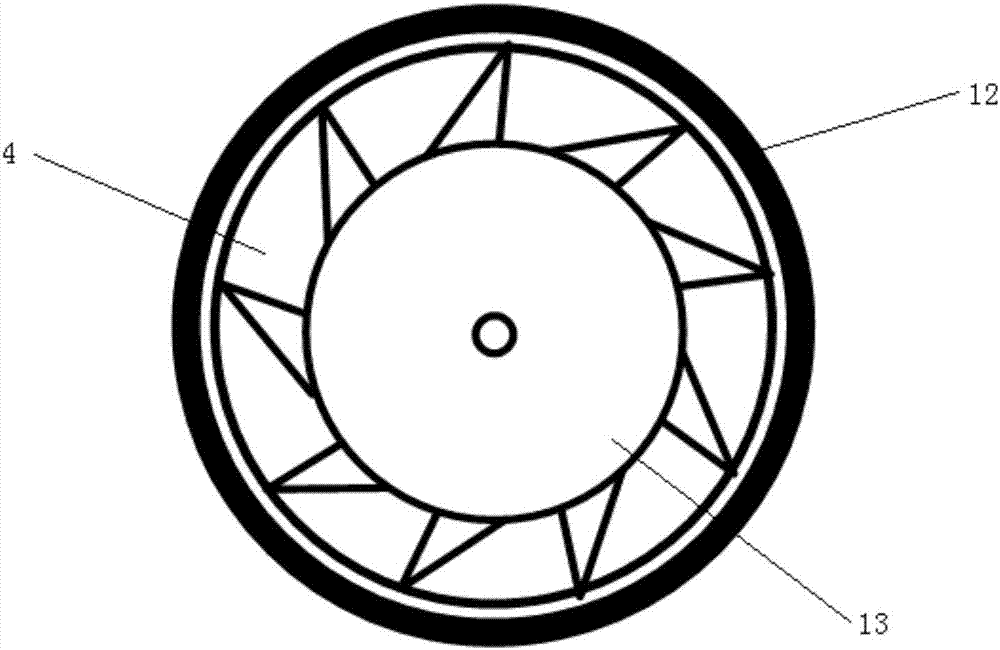

[0022] according to figure 1 , figure 2 with Figure 4 As shown, a vertical take-off and landing fixed-wing unmanned aerial vehicle with a variable torque propeller comprises a fuselage 1, and the middle and tail of the fuselage 1 are respectively equipped with a wing 2 and an empennage 3, and the empennage 3 has at least three The angle between two adjacent empennages 3 is less than 180 degrees, and the empennages 3 distributed on both sides of the fuselage are symmetrically arranged, and an aileron 7 is hinged at the rear edge of the wing 2, and the empennage 3 There is a tail rudder 8 hinged on it. During the flight, the roll of the UAV is controlled by adjusting the aileron 7, and the pitch and yaw of the UAV are controlled by the tail rudder 8. The engine 5 is installed at the top, and two sets of variable torque propellers 6 are installed on the output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com