Trimming and shaping die for combined type automobile parts

An auto parts, combined technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the overall quality of the combined auto parts, the accuracy of the combined auto parts is not up to standard, wear, fatigue, fracture , deformation and other problems, to achieve the effect of environmental protection and no pollution in the preparation process, high qualified rate of finished products, and improved anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

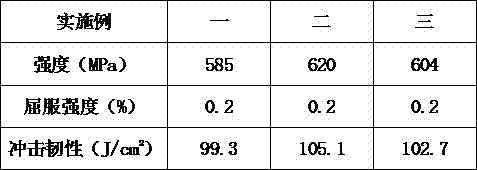

Embodiment 1

[0017] A combined trimming and shaping mold for auto parts proposed by the present invention includes the following raw materials in weight percentage: Al1.8%, Zn 1%, Zr 1.2%, Ni 2.8%, Mn 0.3%, Sn 3%, P 0.2 %, Si 2.2%, rare earth 0.1%, additive 2.8%, and the balance is Cu, wherein the additive is Al with a mass ratio of 2:2.5:1 2 o 3 , ZrC and CrB 2 Compositions.

[0018] Its preparation method comprises the following steps:

[0019] S1. Add the Cu in the weight percentage into the metal smelting furnace, gradually heat and melt at a heating rate of 120°C / min under an inert gas atmosphere, and add the weight percentage in turn while stirring at a speed of 560r / min Al, Sn, Zn, Zr, Ni, Mn, P, Si and rare earth, after the above-mentioned raw materials are completely melted, stop heating, keep warm and continue smelting for 1 hour to obtain mixed metal liquid A;

[0020] S2. Add the additive in the weight percentage to the thermal insulation mixed metal liquid A obtained in st...

Embodiment 2

[0024] A combined trimming and shaping die for auto parts proposed by the present invention includes the following raw materials in weight percentage: Al3.2%, Zn 2%, Zr 1.8%, Ni 5.5%, Mn 0.8%, Sn 6.8%, P 0.35 %, Si 3%, rare earth 0.3%, additive 3.5%, and the balance is Cu, wherein the additive is ZrO with a mass ratio of 2.8:3:1 2 , SiC and ZrB 2 Compositions.

[0025] Its preparation method comprises the following steps:

[0026] S1. Add the Cu in the weight percentage into the metal smelting furnace, and gradually heat and melt at a heating rate of 200°C / min under an inert gas atmosphere, and add the weight percentage in turn while stirring at a speed of 720r / min Al, Sn, Zn, Zr, Ni, Mn, P, Si and rare earth, after the above-mentioned raw materials are completely melted, stop heating, keep warm and continue smelting for 3 hours to obtain mixed metal liquid A;

[0027] S2. Add the additive in the weight percentage to the thermal insulation mixed metal liquid A obtained in s...

Embodiment 3

[0031] A combined trimming and shaping mold for auto parts proposed by the present invention includes the following raw materials in weight percentage: Al2.5%, Zn 1.5%, Zr 1.5%, Ni 3.5%, Mn 0.5%, Sn 5.5%, P 0.28 %, Si 2.5%, rare earth 0.2%, additive 3.2%, and the balance is Cu, wherein the additive is SiO with a mass ratio of 2.4:2.8:1 2 , TiC and CrB 2 Compositions.

[0032] Its preparation method comprises the following steps:

[0033] S1. Add the Cu in the weight percentage into the metal smelting furnace, gradually heat and melt at a heating rate of 160°C / min under an inert gas atmosphere, and add the weight percentage in turn while stirring at a speed of 640r / min Al, Sn, Zn, Zr, Ni, Mn, P, Si and rare earth, after the above-mentioned raw materials are completely melted, stop heating, keep warm and continue smelting for 2 hours to obtain mixed metal liquid A;

[0034] S2. Add the additive in the weight percentage to the thermal insulation mixed metal liquid A obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com