A kind of fast excavation material and shotcrete conveying method of turning rock roadway

A technology of spraying grout and materials, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc. It can solve problems such as belt transportation and spraying grout, and achieve the effects of improving construction efficiency, reducing maintenance costs, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

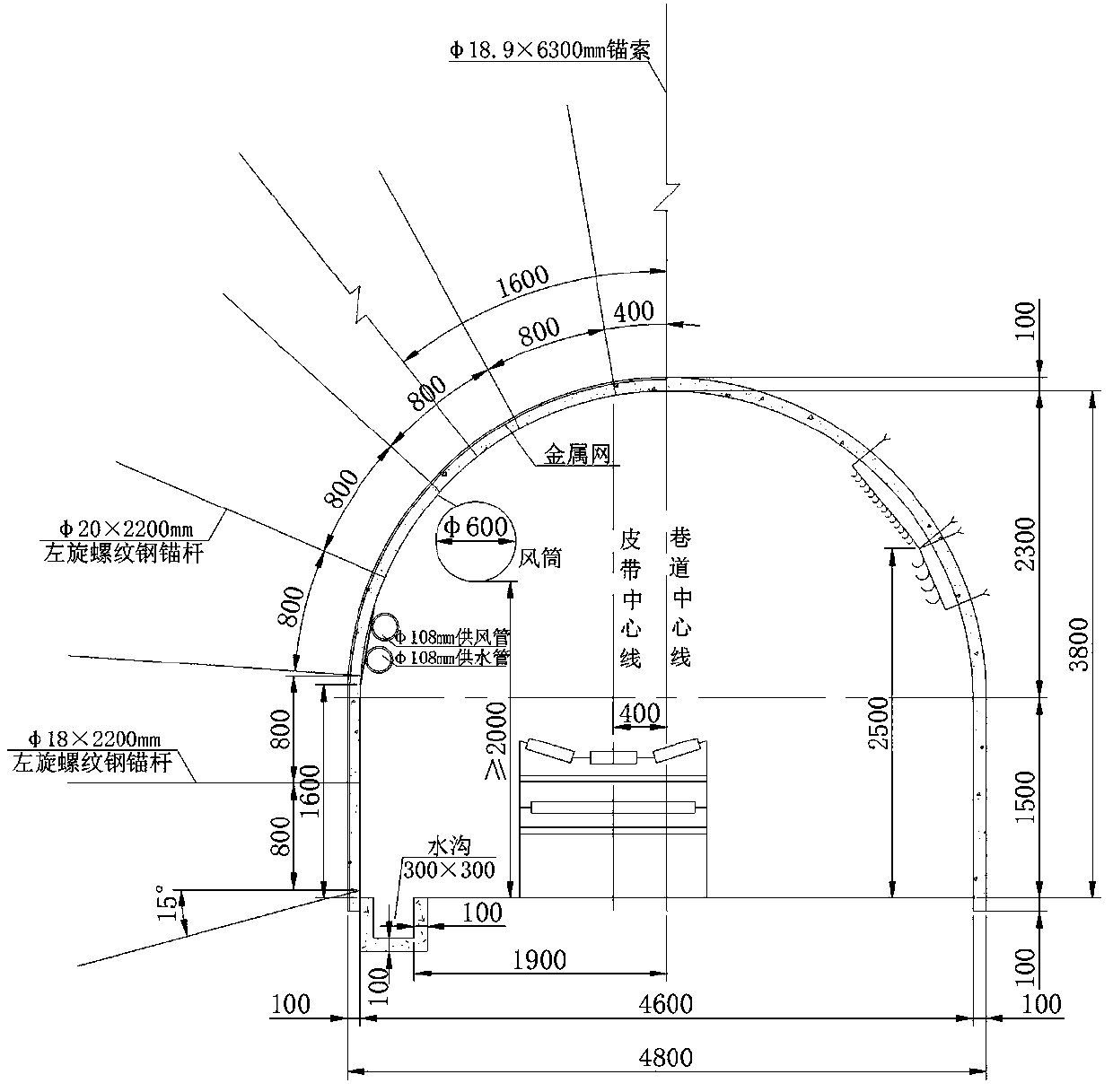

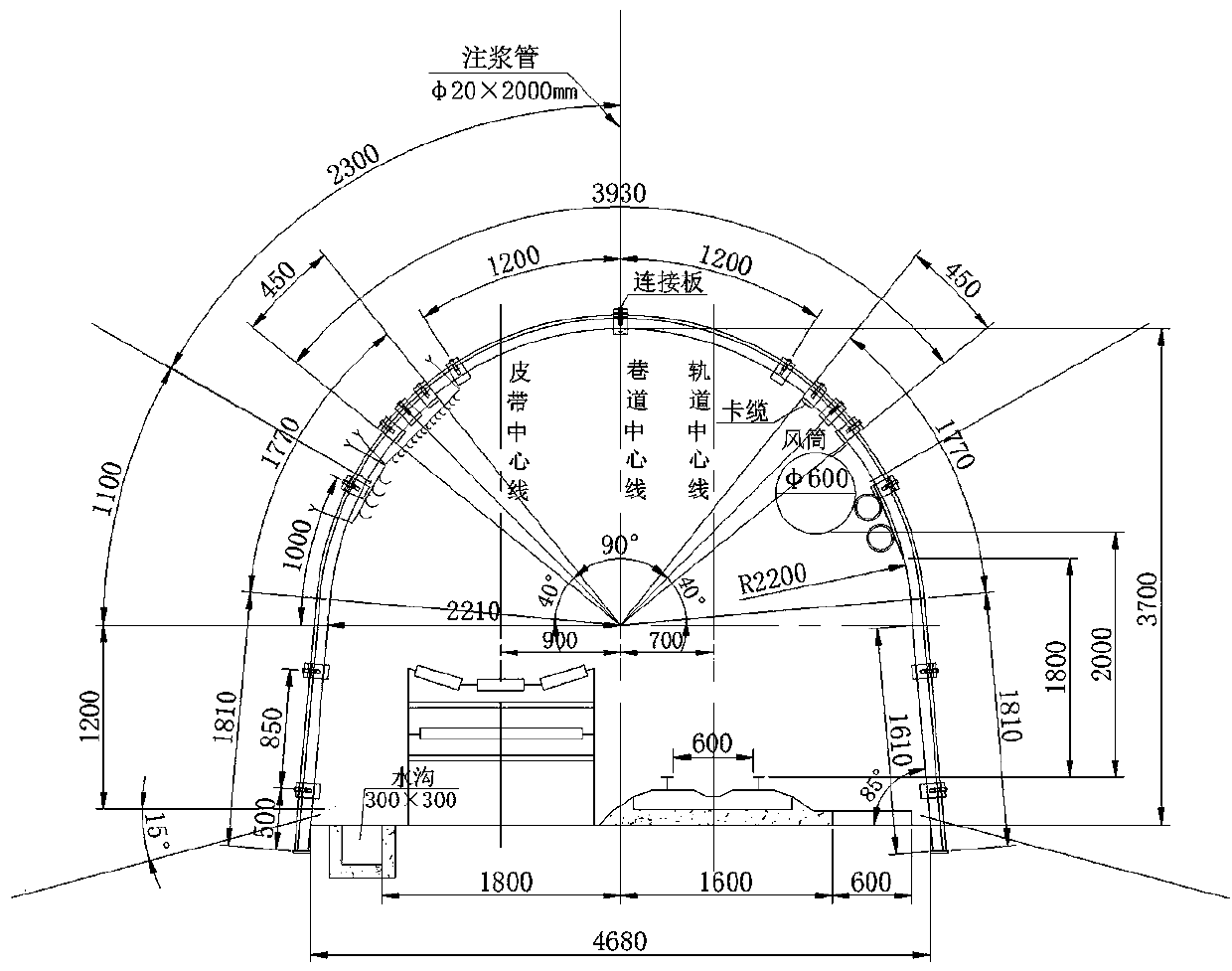

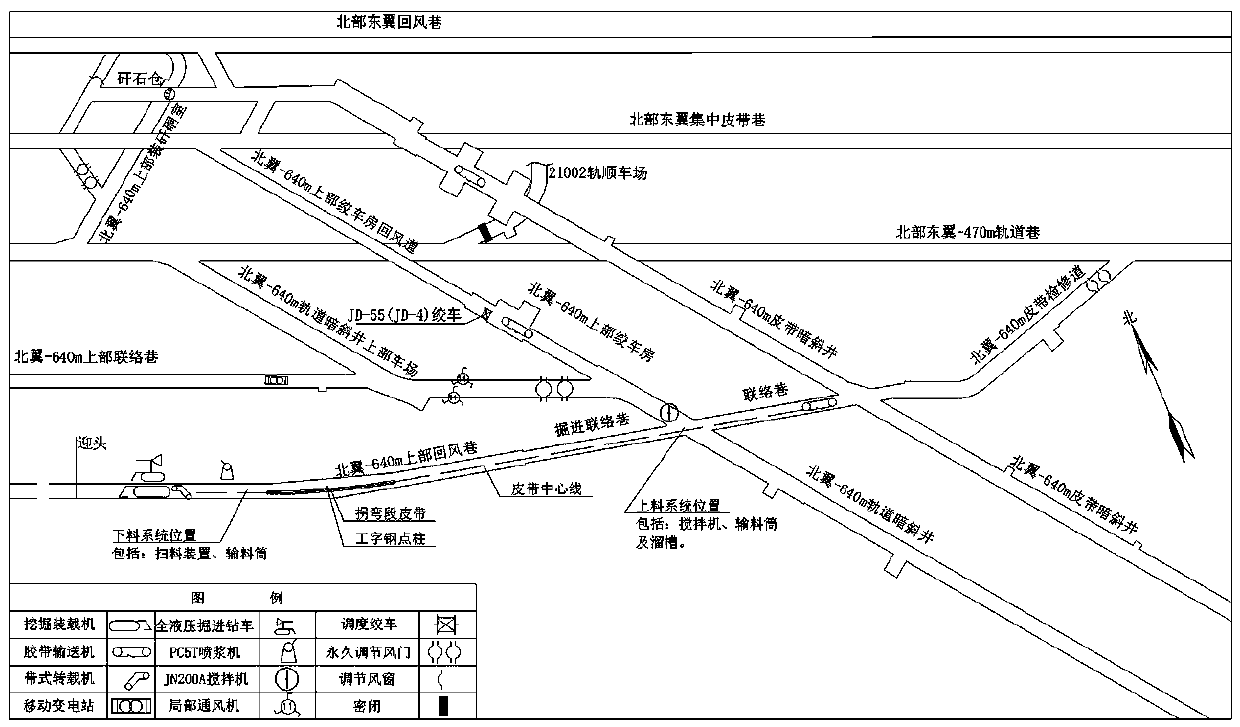

[0034] In order to solve the roadway turning problem in the construction of the return air alley, a turning belt conveyor is installed in the return air alley to transport materials, so that the belt conveyor can realize natural direction change. Turning, two measures are taken in the bending section, namely basic measures and additional measures; the basic measures include:

[0035] 1) Increase the belt turning radius R;

[0036] 2) Make the idler roller at the turn have an installation support angle θ;

[0037] 3) Increase the groove angle θ 0 , θ 0 is the angle formed by the axis of the side roller and the axis of the middle flat roller;

[0038] Additional measures taken include:

[0039] 1) Process the longitudinal beams that conform to the bending radius, that is, shorten the length of the inner longitudinal beams, so that the belt conveyor has the conditions to form a turning radius;

[0040] 2) Process the H frame with slightly higher outer legs, shorten the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com