Light shading plate for low-beam module of automobile headlamp and automobile headlamp

A technology of automobile headlights and visors, which is applied in the direction of shading, components of lighting devices, light sources, etc., can solve the problems of insufficient light in the three areas of low beams, dazzling vehicle drivers, and low visibility of drivers, so as to improve driving safety and driving comfort, reduced dispersion, and increased irradiation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] Example of visor:

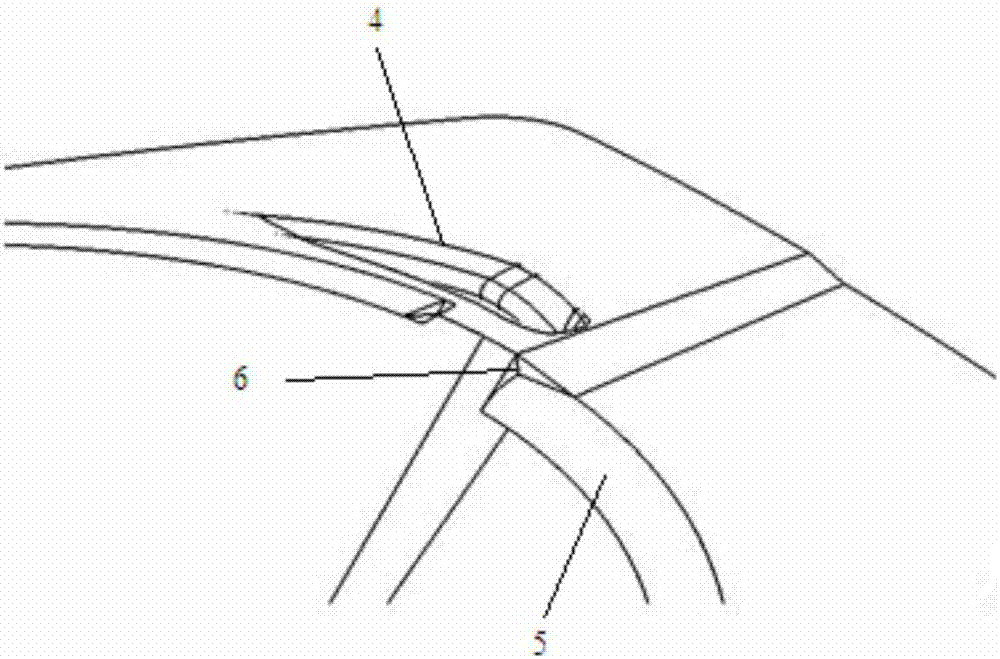

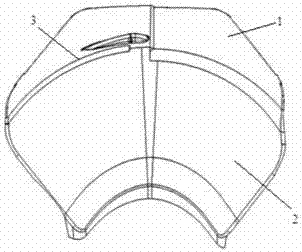

[0032] Such as figure 2 , the shading plate of the present invention comprises two inclined first shading sheets 1 and second shading sheets 2, wherein one end boundary of the first shading sheet intersects with the upper boundary of the second shading sheet, and the first shading sheet The intersecting part of the first light-blocking sheet and the second light-blocking sheet is the cut-off line 3, wherein the first light-blocking sheet is located on the side close to the light source, and the front of the first light-blocking sheet is aluminum-plated to form a reflective surface for reflecting light. The reflective surface is equivalent to image 3 The cut-off line of the single-disk shading sheet shown is a reflective surface formed by stretching toward the light source side at a set angle. The reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com