Refrigerator with food vacuum pre-cooling chamber

A pre-cooling room and vacuum technology, applied in household refrigerators, coolers, household refrigeration devices, etc., can solve the problems of increased load on refrigerator compressors, food spoilage, large cooling consumption, etc., to reduce breathing intensity, prolong Shelf life, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

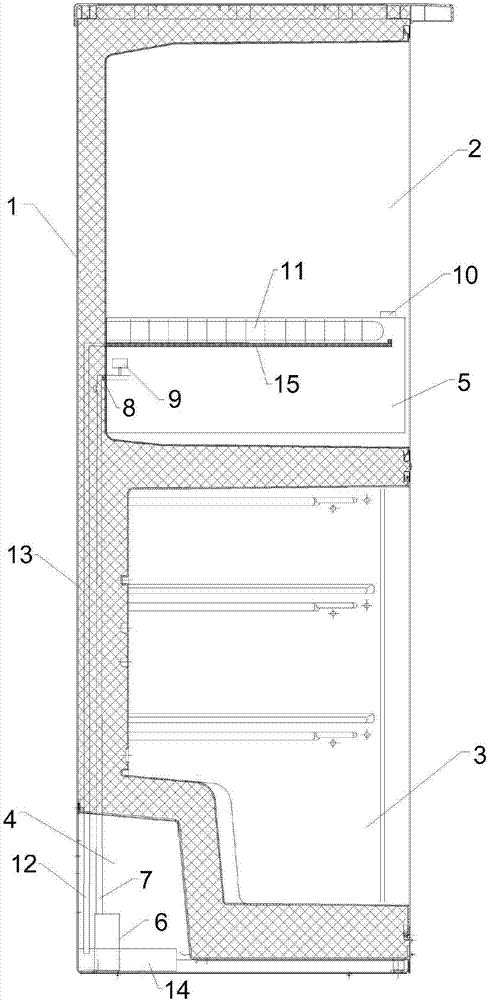

[0023] see figure 1 , the present embodiment is provided with the refrigerator of food vacuum pre-cooling chamber, and wherein, refrigerator 1 upper layer is provided with a refrigerated compartment 2, and lower layer is provided with a freezer compartment 3, and refrigerator 1 cabinet bottom is provided with compressor chamber 4.

[0024] In this embodiment, a vacuum pre-cooling chamber 5 is set in the refrigerating room 2, and the vacuum pre-cooling room 5 is relatively independent and sealed from the refrigerating room 2;

[0025] The compressor compartment 4 is provided with a vacuum pump 6, the air inlet of the vacuum pump 6 is connected with an air extraction pipeline 7, the air extraction pipeline 7 is buried in the foam layer 13 of the refrigerator 1, and the other end is connected with the vacuum precooling chamber 5, and the air extraction The pipeline 7 is provided with a one-way valve 8 for controlling the one-way flow of gas from the vacuum precooling chamber 5 to...

Embodiment 2

[0033] The basic structure of the refrigerator provided with the food vacuum pre-cooling chamber in this embodiment is the same as that in Embodiment 1, the difference is that in this embodiment, one of the independent compartments is set as the vacuum pre-cooling chamber among the multiple compartments of the refrigerator. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com