Automatic PH detection and neutralizing apparatus of washing machine

An automatic detection and washing machine technology, applied in the direction of testing water, material inspection products, non-electric variable control, etc., can solve the problems of unable to meet the needs of automation, waste of resources, unstable detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

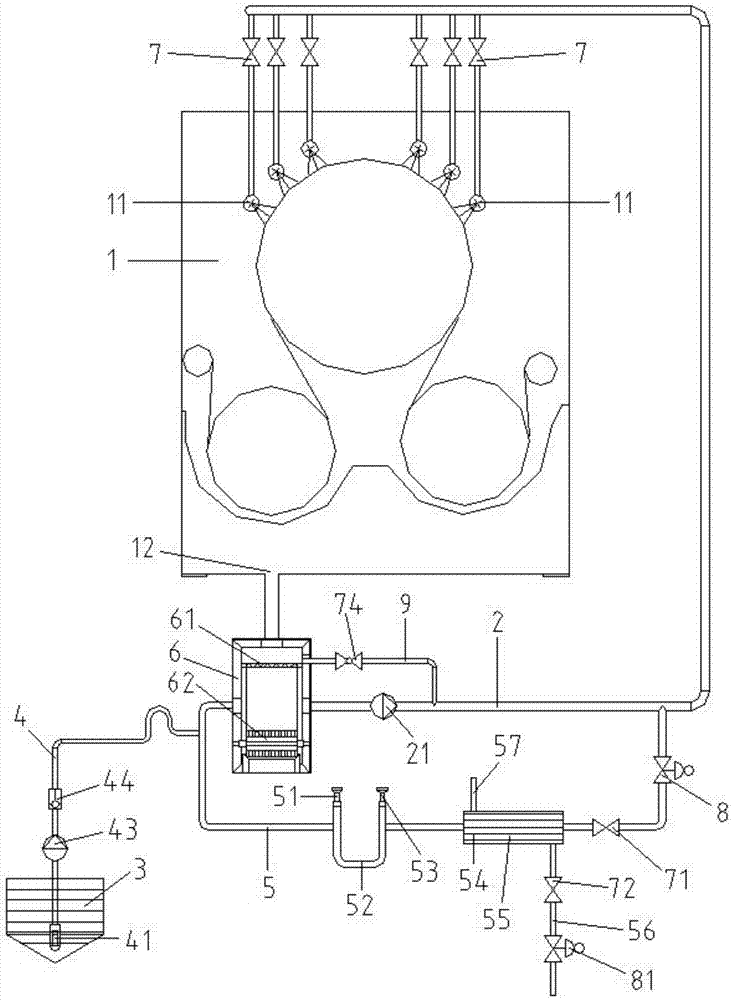

[0013] Such as figure 1 A washing machine PH automatic detection and neutralization device shown includes a circulation pipeline 2 realizing the internal circulation of the washing machine 1, a feeding pipeline 4 connecting the circulation pipeline 2 and the feeding barrel 3, and both ends of the circulation pipeline 2 Connected pH detection line 5. Both ends of the circulation pipeline 2 are respectively connected to the water outlet 12 below the washing machine 1 and the spray device 11 above the washing machine 1 to realize the recycling of water inside the washing machine 1 . A brush filter 6 is installed on the end of the circulation pipeline 2 close to the water outlet 12, and a first shut-off valve 7 for controlling the work of the spray device 11 is installed on the end of the circulation pipeline 2 close to the spray device 11. A circulation pump 21 providing circulation power is installed on the circulation pipeline 2 between the filter 6 and the first shut-off valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com