Measuring method for temperature of molten aluminum alloy liquid

A measurement method and technology of aluminum alloy, applied in the field of metallurgy, can solve the problems of easily damaged temperature measurement, high price of thermocouple, lag infrared temperature measurement process, etc., and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

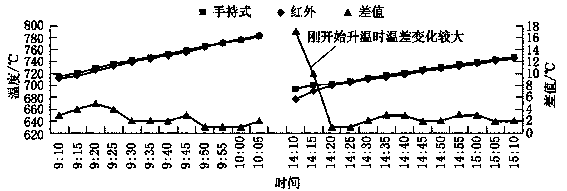

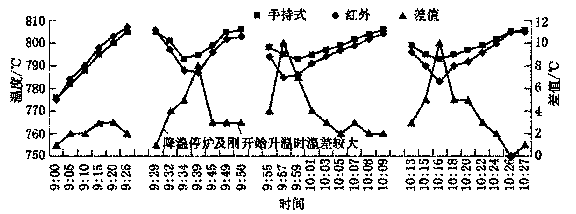

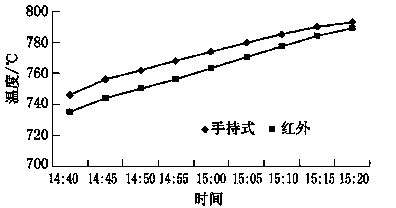

[0007] Working principle: By measuring the infrared energy radiated by the object itself, its surface temperature can be accurately determined, which is the objective basis for infrared radiation temperature measurement.

[0008] The method for measuring the temperature of the aluminum alloy melt is composed of an optical system, an infrared radiation colorimetric thermometer, a signal amplifier, signal processing, and display output. The optical system gathers the target infrared radiation energy in its field of view, and the size of the field of view is determined by the optical parts of the thermometer and its position. The infrared energy is focused on the infrared radiation colorimetric thermometer and converted into a corresponding electrical signal. The signal passes through the amplifier and signal processing circuit, and is converted into the temperature value of the measured target after being corrected according to the algorithm of the instrument and the emissivity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com