Method for measuring the internal reflection coefficient of photovoltaic ribbon and measuring i of different ribbon components sc method of difference

A technology of photovoltaic welding ribbon and measurement method, which is applied in the field of solar cells, can solve the problem of inability to measure the internal reflection coefficient of the welding ribbon, and achieve the effect of avoiding power loss and simplifying the evaluation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment is a method for measuring the internal reflection coefficient of a photovoltaic ribbon, comprising the following steps:

[0069] Step a): Select 10 pieces of 5-busbar monocrystalline cells with a side length of 156.75mm and an area of 244cm 2 , the Isc distribution of these 10 cells is in the range of 9.5A-9.51A, the reflectivity is in the range of 5%-5.5%, and the SiN refractive index is distributed in the range of 2.04-2.07;

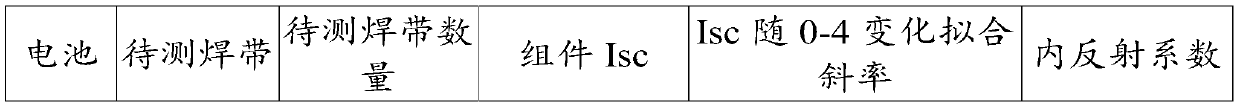

[0070] Divide the above 10 cells into 2 groups, 5 cells in each group, numbered C1-C5 and D1-D5 in sequence, where C1-C5 is one group and D1-D5 is another group;

[0071] Step b): Solder the front and back sides of the above 10 cells with welding strips and bus bars respectively;

[0072] Step c): Place the solder ribbon A to be tested (0.9mm in width and 160mm in length) on the surface of the cells C1-C5, and place the solder ribbon B to be tested (0.9mm in width and 160mm in length) on the cell surfaces of C6-C10;

[0073] ...

Embodiment 2

[0097] This embodiment is a method for measuring the internal reflection coefficient of a photovoltaic ribbon, comprising the following steps:

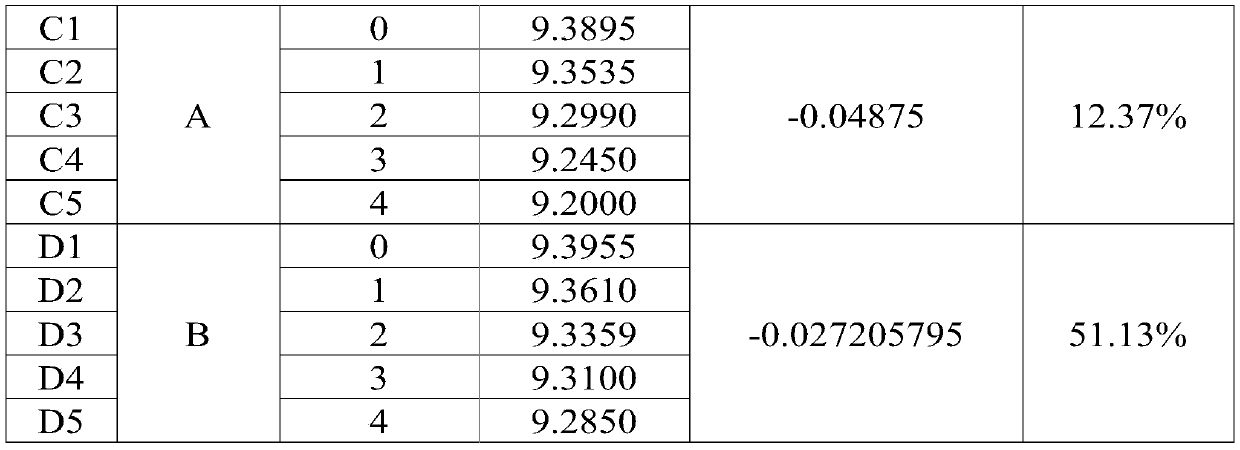

[0098] Step a): Select 10 pieces of 5-busbar monocrystalline cells with a side length of 156.75mm and an area of 244cm 2 , the Isc distribution of these 10 solar cells is in the range of 9.5A-9.51A, the reflectivity is in the range of 5%-5.5%, and the SiN refractive index is distributed in the range of 2.04-2.07; the above 10 solar cells are numbered sequentially as C1-C10;

[0099] Step b): Solder the front and back sides of the above 10 cells with welding strips and bus bars respectively;

[0100] Step c): Place the solder strip C (width 0.9mm, length 160mm) on the surface of the cell C1-C10;

[0101] C1 cell does not put extra solder ribbon C to be tested, C2 cell puts 1 solder ribbon C to be tested, C3 cell puts 2 solder ribbons C to be tested, C4 cell puts 3 solder ribbons C to be tested,... , and so on, put 9 solder ribbons...

Embodiment 3

[0110] This embodiment is a method for measuring the internal reflection coefficient of a photovoltaic ribbon, comprising the following steps:

[0111] Step a): Select 2 pieces of 5-busbar monocrystalline cells with a side length of 156.75mm and an area of 244cm 2 , the Isc distribution of these two cells is in the range of 9.5A-9.51A, the reflectivity is in the range of 5%-5.5%, and the SiN refractive index is distributed in the range of 2.04-2.07; the above 10 cells are numbered in turn as C1-C2;

[0112] Step b): Solder the front and back sides of the above two cells with welding strips and bus bars respectively;

[0113] Step c): Place the solder strip D (width 0.9mm, length 160mm) on the surface of the battery sheet of C1-C2;

[0114] The C1 cell does not put an extra solder ribbon D to be tested, and the C2 cell puts one solder ribbon D to be tested;

[0115] Step d): The method of placing the soldering ribbon C to be tested in the step c) is: place the soldering ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com