A Three-level Active Third Harmonic Injection Matrix Converter with T-Type Structure

A sub-harmonic and three-level technology, which is applied in the direction of converting AC power input to AC power output, converting AC power input to DC power output, and output power conversion devices, can solve the problem of low power density and reliability, energy One-way flow, excessive output voltage harmonics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

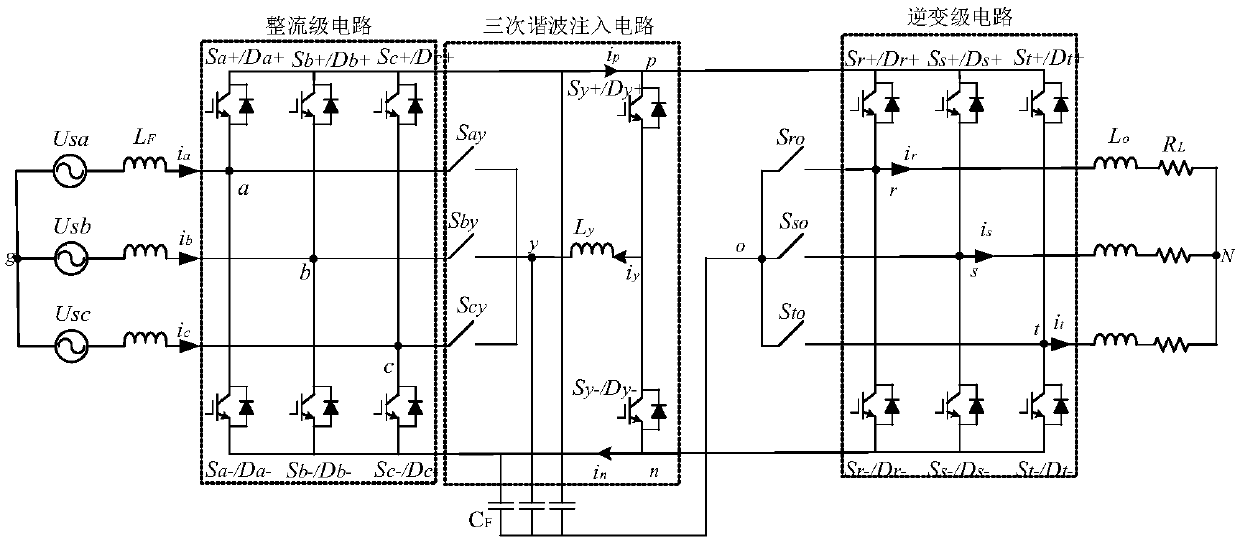

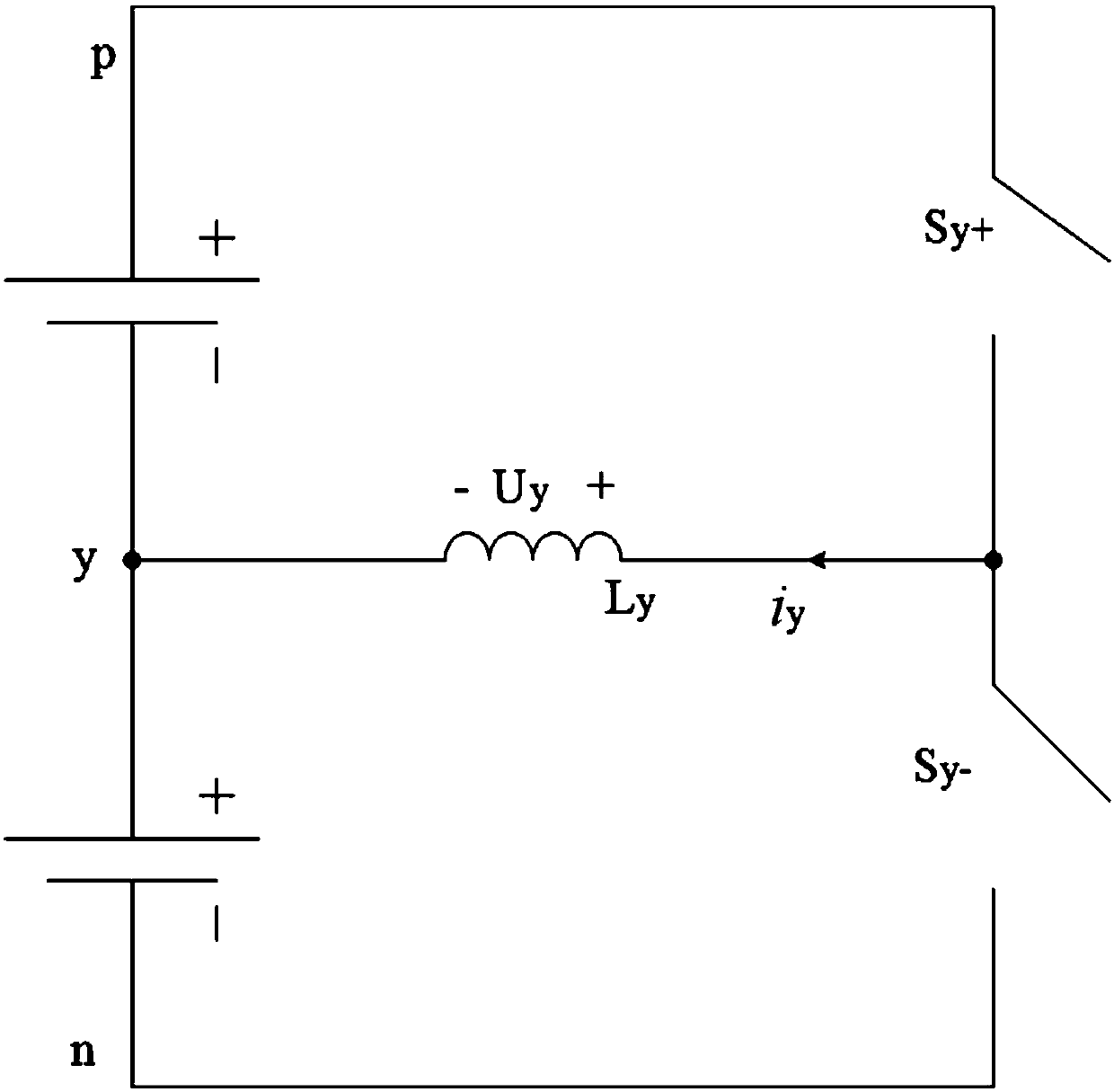

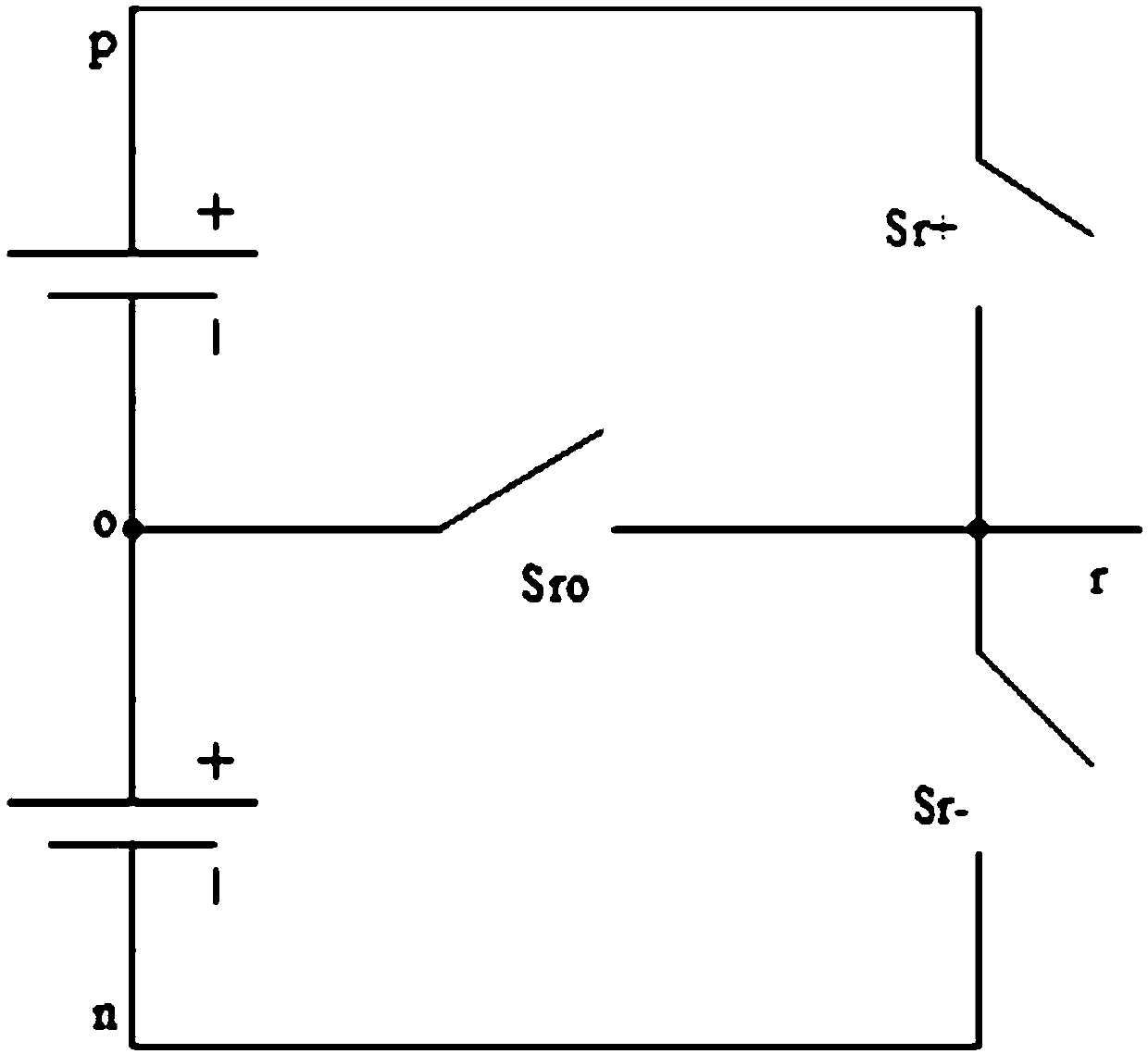

[0039] In order to overcome the disadvantages of unidirectional flow of energy, poor input current quality, low power density and reliability in the prior art, and the existence of dual-level active third harmonic injection matrix converters, the harmonics of the output voltage are too large at the same time The problem. There is a T-shaped three-level active third harmonic injection matrix converter in the matrix converter, such as figure 1 As shown, including: rectification stage circuit, third harmonic injection circuit, inverter stage circuit and input LC filter;

[0040] The input end of the rectification stage circuit is connected to the three-phase input power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com