Resistance spot welding device for aluminum-steel special plate welding and welding method

A technology of resistance spot welding and resistance spot welding machine, which is applied in the direction of welding/welding/cutting items, resistance welding equipment, welding equipment, etc., which can solve the problems of warping and deformation of aluminum plates, low production efficiency, unsafe operation, etc., and achieve suppression Effects of warpage deformation, high production efficiency, and simplified rotating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

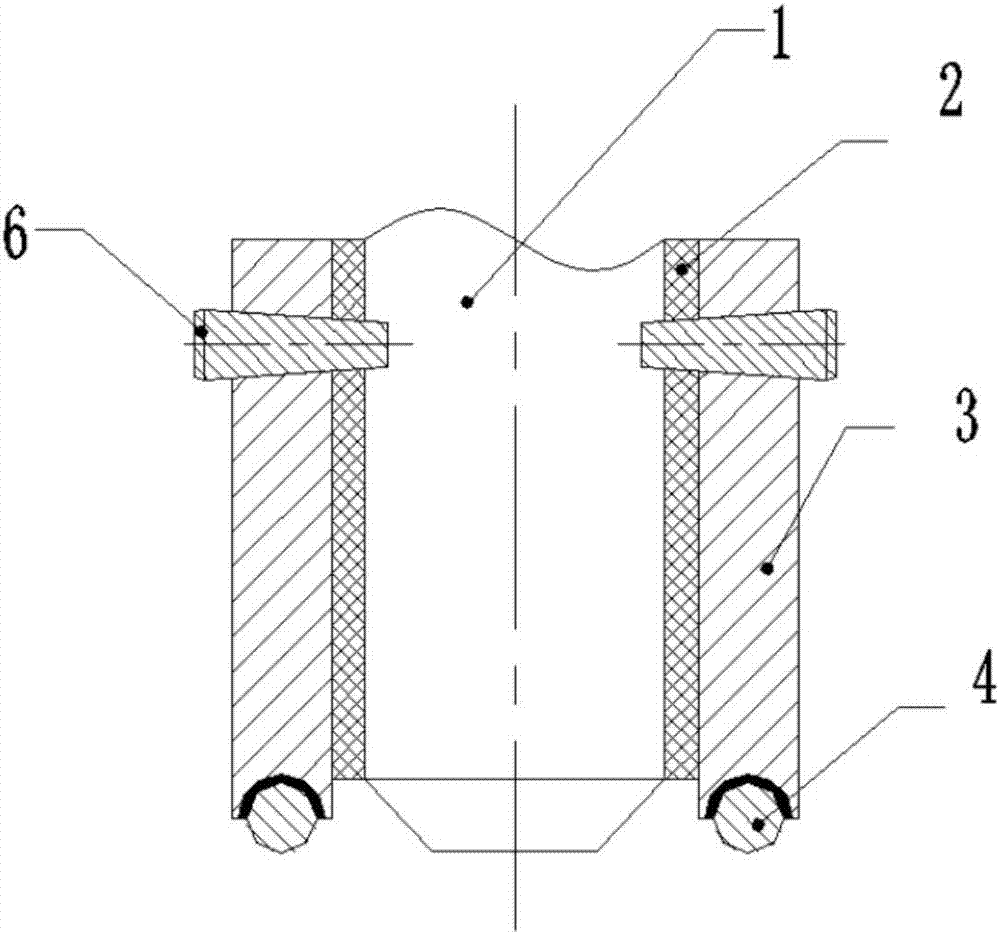

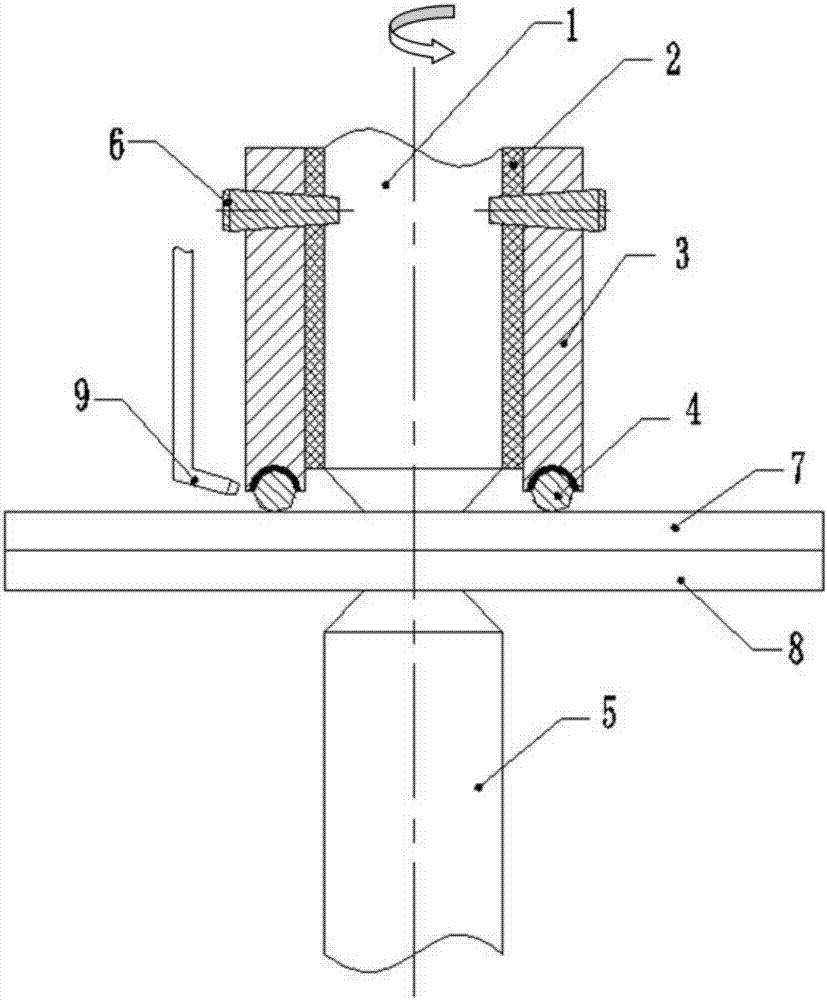

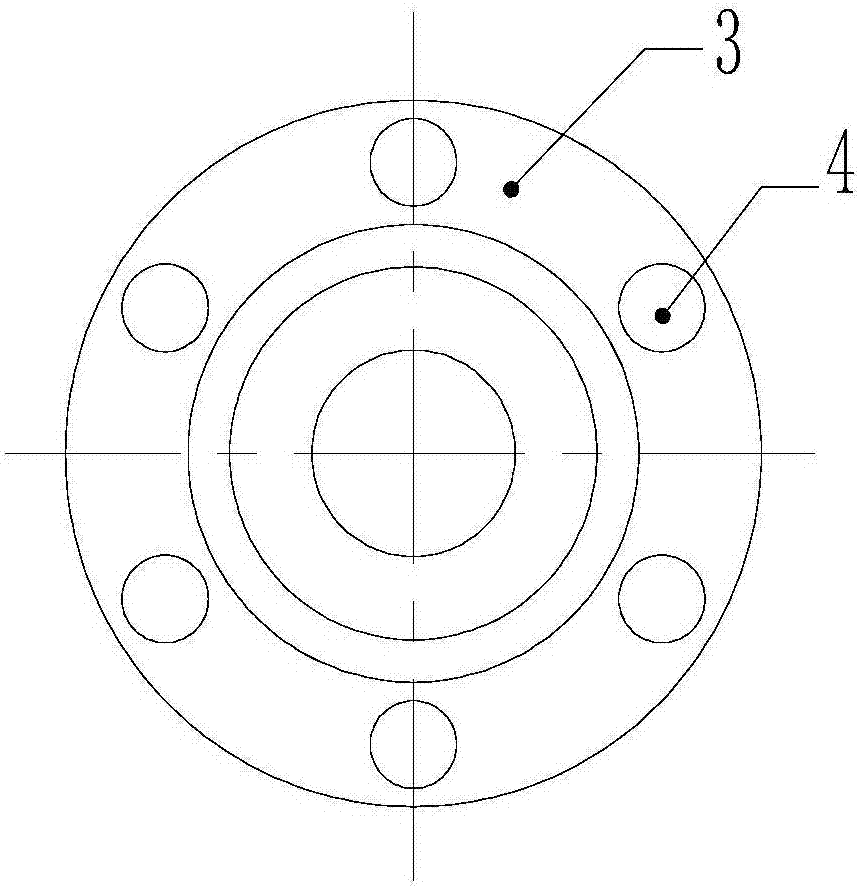

[0037] Embodiment 1, with reference to attached figure 1, 2 , 3, the thickness of the aluminum plate 7 to be welded and the steel plate 8 to be welded are 1mm; the diameter of the center copper electrode 1 of the resistance spot welding device is 16mm, the wall thickness of the insulating ring 2 is 0.5mm, and the wall thickness of the steel sleeve 3 is 6mm. The diameter of the hard wear-resistant steel ball 4 is 5 mm, the diameter of the lower copper electrode 5 is 16 mm, and the bottom plane formed by the hard wear-resistant steel ball 4 is 0.3 mm higher than the lower surface of the central copper electrode.

[0038] The method for welding aluminum-steel dissimilar materials by using the above-mentioned resistance spot welding device comprises the following steps:

[0039] 1) Fix the steel plate 8 to be welded horizontally on the welding table of the resistance spot welding machine, place the aluminum plate 7 to be welded on the upper surface of the steel plate 8 to be weld...

Embodiment 2

[0045] Embodiment 2, with reference to attached figure 1 , 2 , 3, the thickness of the aluminum plate 7 to be welded and the steel plate 8 to be welded are 1.5mm; the center copper electrode 1 diameter of the resistance spot welding device is 16mm and the wall thickness of the insulating ring 2 is 0.8mm, and the wall thickness of the steel sleeve 3 is 8mm, The diameter of the hard wear-resistant steel ball 4 is 6 mm, the diameter of the lower copper electrode 5 is 16 mm, and the bottom plane formed by the hard wear-resistant steel ball 4 is 0.5 mm higher than the lower surface of the central copper electrode.

[0046] The method for welding aluminum-steel dissimilar materials by using the above-mentioned resistance spot welding device comprises the following steps:

[0047] 1) Fix the steel plate 8 to be welded horizontally on the welding table of the resistance spot welding machine, place the aluminum plate 7 to be welded on the upper surface of the steel plate 8 to be welde...

Embodiment 3

[0053] Embodiment 3, with reference to attached figure 1 , 2 , 3, the plate thickness of the aluminum plate 7 to be welded and the steel plate 8 to be welded are 2mm; the diameter of the center copper electrode 1 of the resistance spot welding device is 16mm and the wall thickness of the insulating ring 2 is 1mm, and the wall thickness of the steel sleeve 3 is 10mm, hard The ball diameter of the wear-resistant steel ball 4 is 8 mm, the diameter of the lower copper electrode 5 is 16 mm, and the bottom plane formed by the hard wear-resistant steel ball 4 is 0.5 mm higher than the lower surface of the central copper electrode.

[0054] The method for welding aluminum-steel dissimilar materials by using the above-mentioned resistance spot welding device comprises the following steps:

[0055] 1) Fix the steel plate 8 to be welded horizontally on the welding table of the resistance spot welding machine, place the aluminum plate 7 to be welded on the upper surface of the steel plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com