Stirring machine for mixed fish forages

A mixer and fish feed technology, applied in the direction of mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of unable to meet the daily production needs of factory fish farms, poor utilization rate of fish feed, unstable quality, etc. , to achieve the effect of high production efficiency, good quality and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

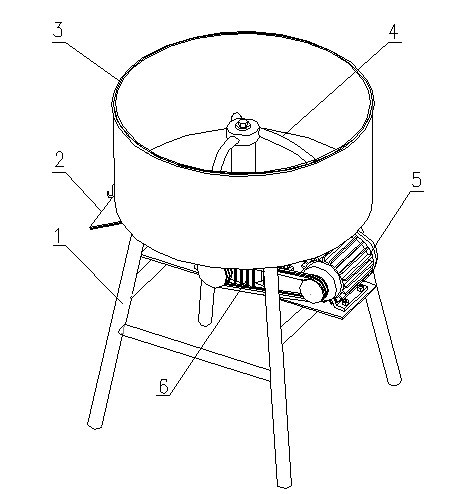

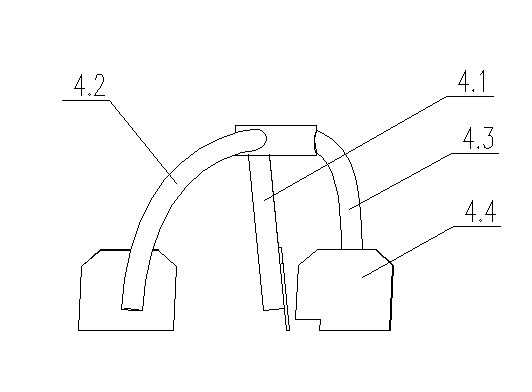

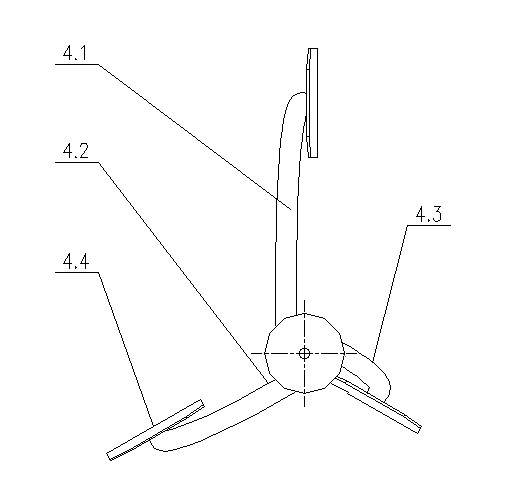

[0015] figure 1 The mixed fish feed mixer shown is a vertical mixing machine, including an underframe 1, a discharge trough 2, a barrel 3, a crank arm assembly 4, a motor 5 and a reducer 6. The material barrel 3 is a cylindrical open container, and the material barrel 3 facing upwards is installed on the bottom frame 1, and the bottom plate of the material barrel 3 is provided with a discharge opening controlled by a movable shutter. The discharge trough 2 is located under the discharge opening and is fixedly connected with the inside high and the outside low. This structure is convenient for the dropped mixed fish feed to be discharged along the slope of the discharge chute 2. The bottom end of the middle shaft of the crank arm assembly 4 built in the barrel 3 runs through the bottom plate and is connected with the lower reducer 6 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com