Walking wheel assembly

A traveling wheel and assembly technology, applied in conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of difficult disassembly and maintenance of rotating systems, complex orbital rotating systems, and large space for avoidance, and achieve compact structure. , The effect of flexible rotation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

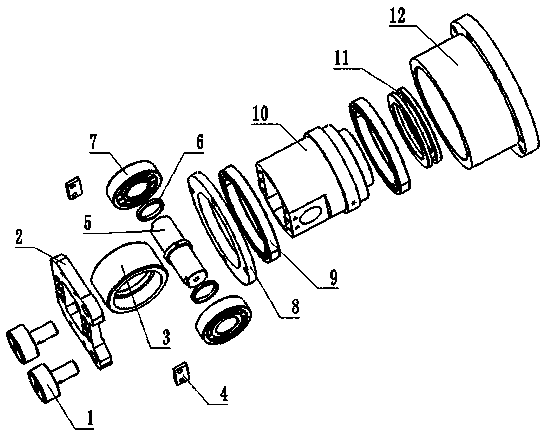

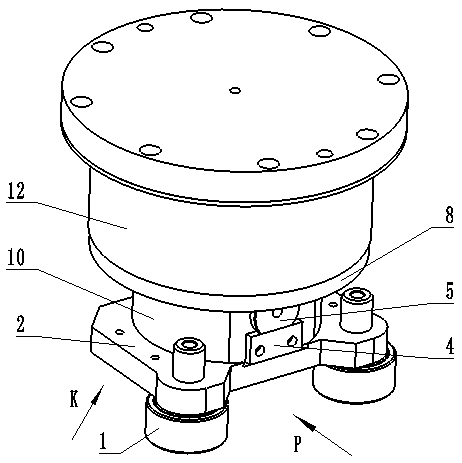

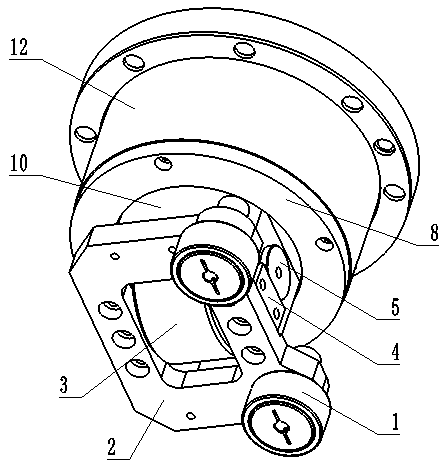

[0021] Such as figure 1 , figure 2 , image 3 A walking wheel assembly shown includes a load-bearing shaft 12 rotatably connected to the upper part of the rotating shaft 10 for placing a fixture. The axis line is basically vertical. The rotating shaft 10 has a cavity with an opening downward, and the traveling wheel 3 is located in the cavity and is mounted on the rotating shaft 10 by the wheel shaft 5. Two first bearings 7 are housed between the wheel shaft 5 and the traveling wheel 3, and the two second bearings An axial limit block fixed on the wheel shaft 5 is installed between the first bearings 7, a spacer 6 is installed on the outer end of the first bearing 7, and a first oil hole for delivering lubricating oil to the first bearing 7 is provided on the wheel shaft 5 ; The first bearing 7 of this embodiment adopts a cylindrical roller bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com