Production method of medicinal plastic bag

A production method and technology for plastic bags, applied in the field of hygienic packaging, can solve the problem that the formula cannot meet user requirements, etc., and achieve the effects of good water vapor permeability and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A production method of a medicinal plastic bag, wherein: raw materials and their percentages are as follows: polyethylene 5000S 50%;

[0015] Low density polyethylene 2426H 25%;

[0016] Metallocene linear polyethylene 3505HH 25%.

[0017] The production method steps are as follows:

[0018] 1) Feed polyethylene 5000S, low-density polyethylene 2426H and metallocene linear polyethylene 3505HH into the mixer according to the above ratio, and mix them uniformly at a temperature of 180°C to form a blank; then put the blank into a plastic granulator , plasticized and cut out particles at a temperature of 180°C;

[0019] 2) Throw the particles into the hopper of the film blowing machine, heat up to 180°C and extrude the film;

[0020] 3) Put the film into a sealing and cutting machine to seal and cut into medical plastic bags.

Embodiment 2

[0022] A production method of a medicinal plastic bag, wherein: raw materials and their percentages are as follows: polyethylene 5000S 50%;

[0023] Low density polyethylene 2426H 25%;

[0024] Metallocene linear polyethylene 3505HH 25%.

[0025] The production method steps are as follows:

[0026] 1) Feed polyethylene 5000S, low-density polyethylene 2426H and metallocene linear polyethylene 3505HH into the mixer according to the above ratio, and mix them uniformly at a temperature of 200°C to form a blank; then put the blank into a plastic granulator , plasticized and cut out particles at a temperature of 300°C;

[0027] 2) Throw the particles into the hopper of the film blowing machine, heat up to 230°C and extrude the film;

[0028] 3) Put the film into a sealing and cutting machine to seal and cut into medical plastic bags.

Embodiment 3

[0030] A production method of a medicinal plastic bag, wherein: raw materials and their percentages are as follows: polyethylene 5000S 50%;

[0031] Low density polyethylene 2426H 25%;

[0032] Metallocene linear polyethylene 3505HH 25%.

[0033] The production method steps are as follows:

[0034] 1) Feed polyethylene 5000S, low-density polyethylene 2426H and metallocene linear polyethylene 3505HH into the mixer according to the above ratio, and mix them uniformly at a temperature of 1900°C to form a blank; then put the blank into a plastic granulator , plasticized and cut out particles at a temperature of 250°C;

[0035] 2) Throw the particles into the hopper of the film blowing machine, heat up to 200°C and extrude the film;

[0036] 3) Put the film into a sealing and cutting machine to seal and cut into medical plastic bags.

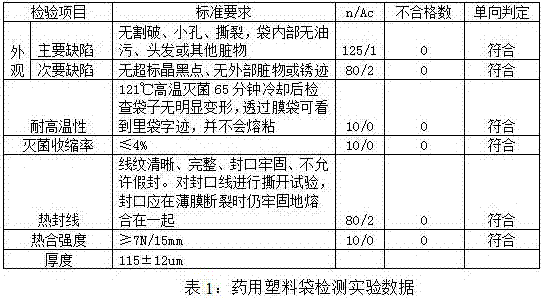

[0037] According to the following table 1 of the medical plastic bag detection result that above-mentioned embodiment one to three produces:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com