Control system for automatically preparing aqueous-phase solution of emulsified explosive

An automatic preparation and control system technology, which is applied in the direction of explosives, explosives composite components, explosives processing equipment, etc., can solve the problems of high computing power requirements for batching operators, the need to improve the automation level, and increase the workload of the squad leader, so as to achieve the essence of upgrading Safety level, improvement of automation level, effect of labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

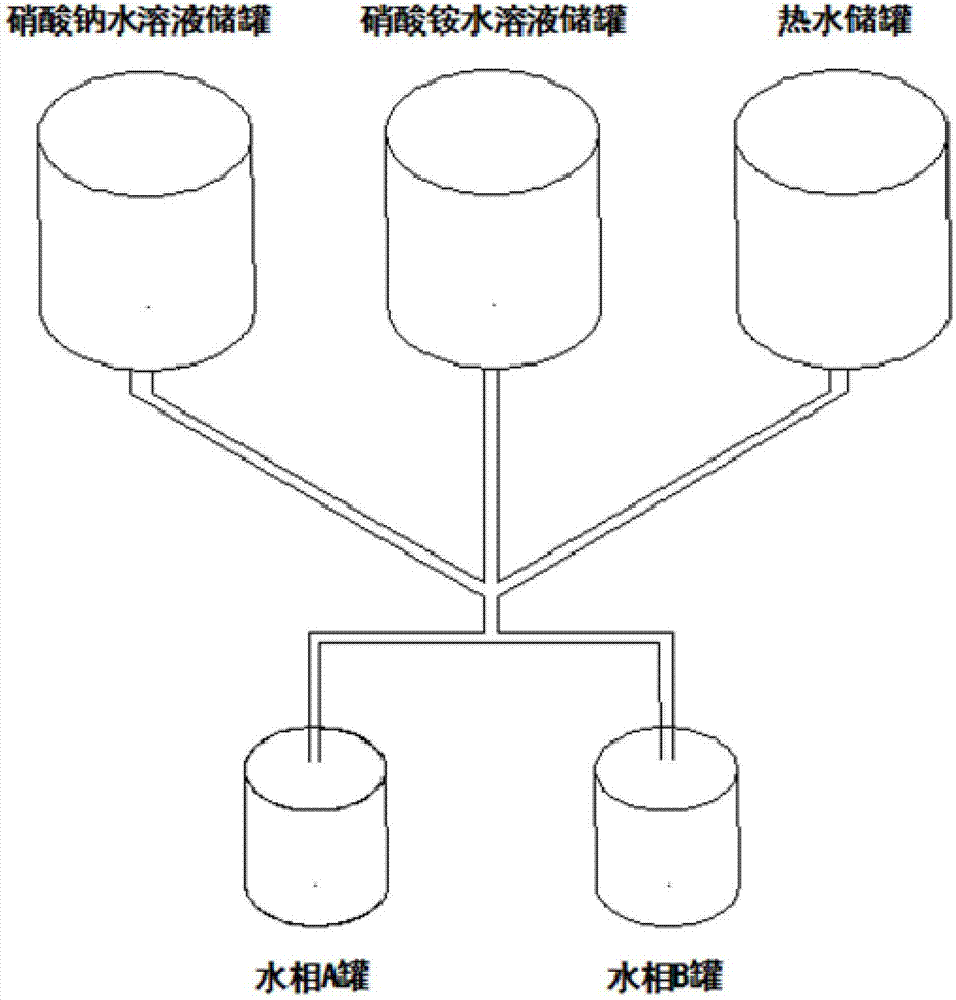

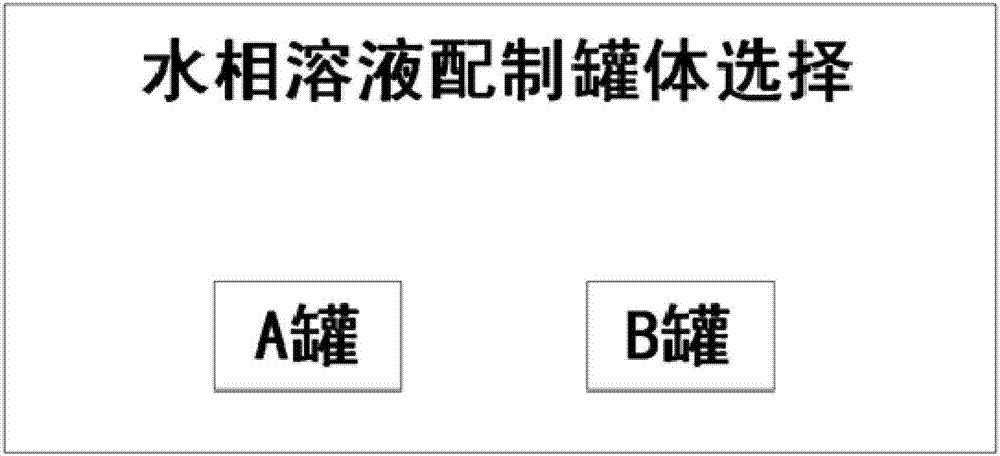

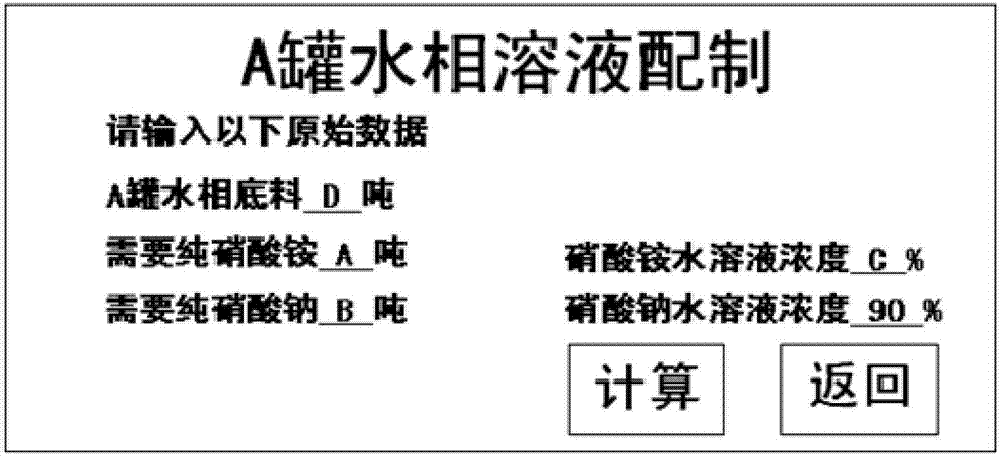

[0035] refer to Figure 1 to Figure 6 , the present invention adds a sodium nitrate aqueous solution storage tank and a hot water storage tank on the basis of the existing production equipment, a steam coil needs to be installed in the sodium nitrate aqueous solution storage tank, an electronic scale is installed at the bottom, and a steam coil needs to be installed in the hot water storage tank. At the same time, it is necessary to install an automatic detection and display device for the density of the water phase in the two water phase tanks. The size of the newly added sodium nitrate aqueous solution and hot water storage tanks can be determined according to the daily production demand, and the design size can meet the production demand of the shift or the day; the spatial layout of each storage tank is as follows figure 1 .

[0036] The concentration of solution in the ammonium nitrate aqueous storage tank is C% (known), and the temperature in the storage tank is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com