Air compressor noise reduction pipe

An air compressor and noise reduction technology, which is applied in the field of connecting pipes, can solve the problems of not being able to meet the market demand, the working environment is not optimistic, and increase the noise reverberation, and achieve the effect of easy promotion, convenient installation, and reduced vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

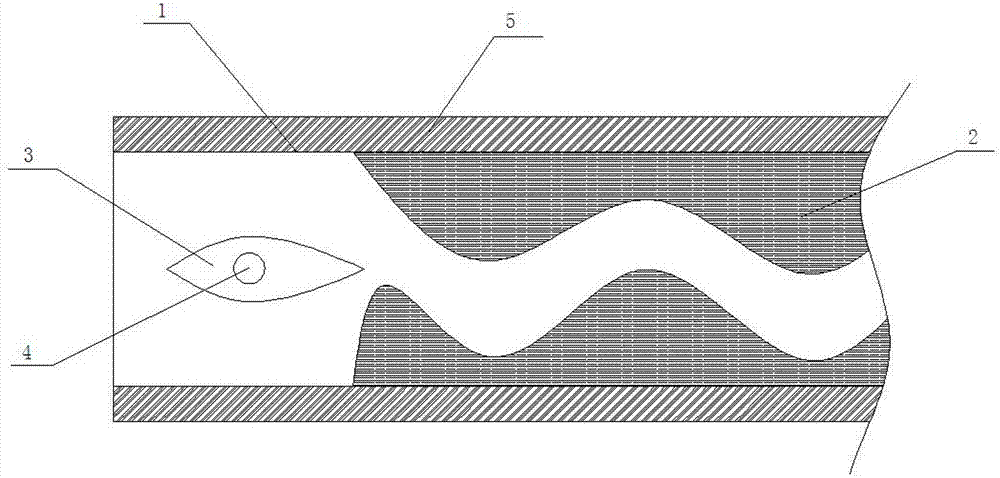

[0018] An air compressor noise reduction tube, including a tube body 1; it is characterized in that: one end of the tube body 1 is provided with a shuttle-shaped airflow buffer 3, and the two sides of the shuttle-shaped airflow buffer 3 are connected by connecting rods 4 On the inner wall of the pipe body 1; the inside of the pipe body 1 is provided with a shock-absorbing and impact-resistant material 2 behind the shuttle-shaped airflow buffer 3, and the shock-absorbing and impact-resistant material 2 forms a spiral channel inside the pipe body 1; the pipe A sound-insulating material layer 5 is provided on the outer wall of the body 1 .

[0019] The sound-insulating material layer 5 is made of sound-insulating cotton.

[0020] The shock-absorbing and impact-resistant material 2 is made of rubber.

Embodiment 2

[0022] Working principle of the present invention: the present invention divides the air entering the pipe through the shuttle-shaped airflow buffer 3, thereby reducing the pressure of the air in the pipe, and reduces the impact force of the air through the shock-absorbing and impact-resistant material 2 in the pipe, and at the same time Compressed air flows in the path inside the tube, and the spiral channel formed in the tube prolongs the flow path of the air, increases the flow distance, reduces the flow velocity of the air, and increases the thickness of the tube body 1, increasing the shock absorption method, thereby The noise generated by high-speed air flow is reduced; and the noise inside the pipe body 1 is further reduced by wrapping the pipe wall with the sound-insulating material layer 5 , achieving a good noise reduction purpose.

Embodiment 3

[0024] The present invention is suitable for high-speed airflow transmission device, which is convenient to reduce the noise generated by high-speed air flow, effectively reduces the vibration frequency in the high-speed air flow, and further absorbs the generated noise through the outer layer of sound-absorbing material or diffuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com