Flame-retarding lacquer putty and preparation method thereof

A putty and raw material technology, applied in the direction of filling slurry, etc., can solve the problems that putty has no flame retardancy, putty heat resistance and flame retardancy can not meet special strict requirements, etc., to reduce the effect, improve heat resistance, gas good dry performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

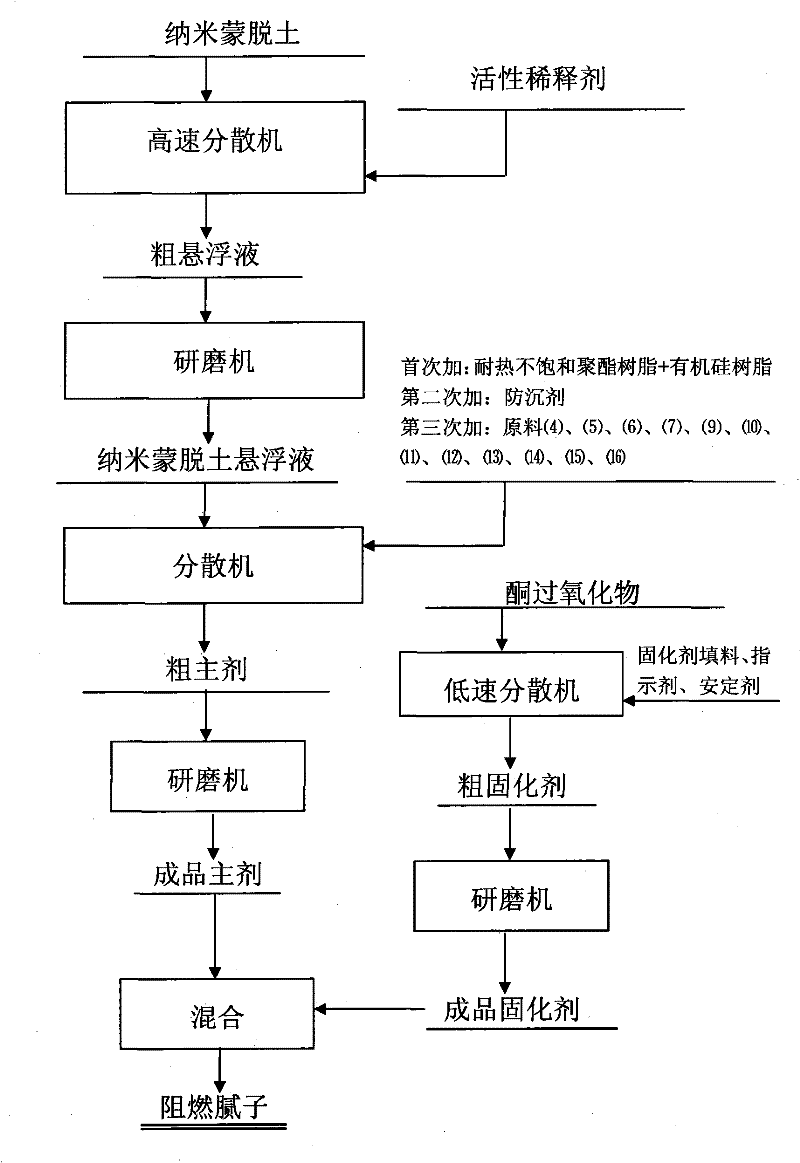

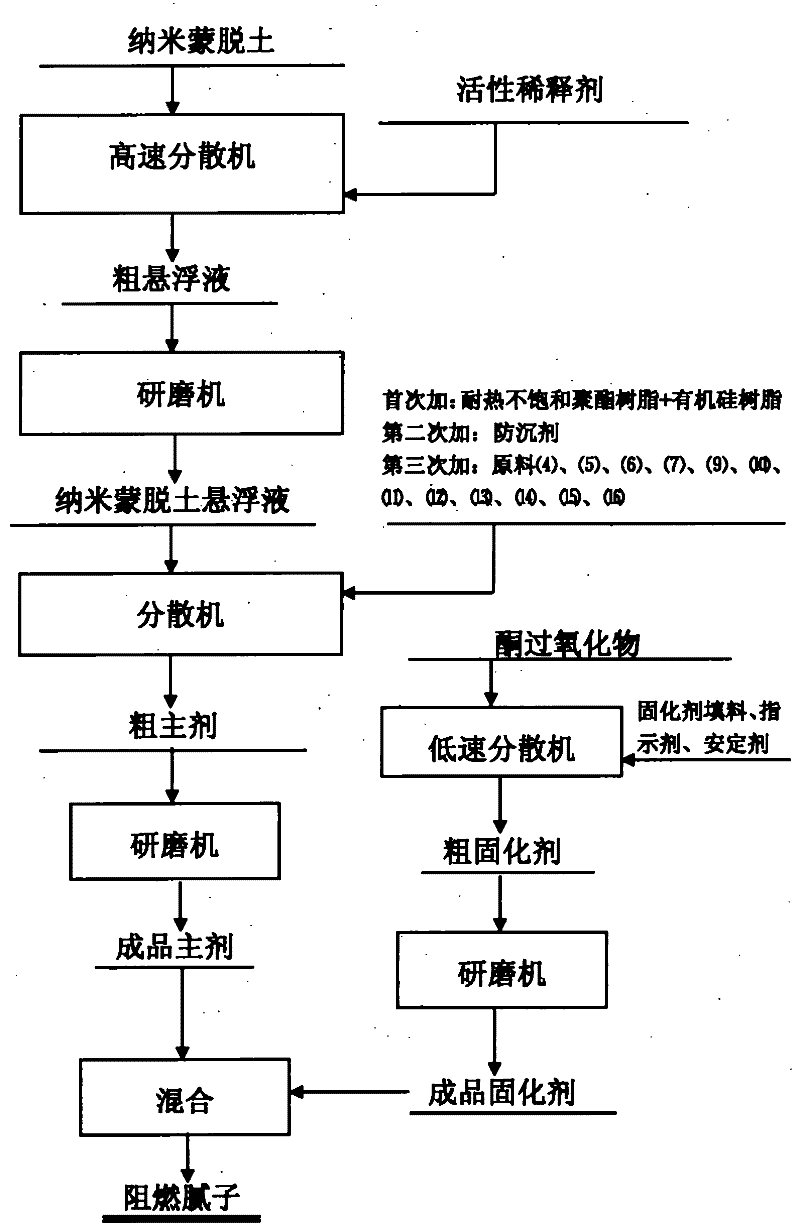

Method used

Image

Examples

preparation example Construction

[0046] B. The preparation of the curing agent is to put the four kinds of raw materials (18)-(21) into the low-speed disperser. After dispersion, the output rough curing agent is produced. The rough curing agent is ground to produce the finished curing agent. tube packaging, ready to use;

[0047] C. Preparation of flame retardant putty. When in use, mix the main agent of the finished product and the finished curing agent in a weight ratio of 100:3-5 to obtain the flame retardant putty of the present invention.

[0048] The flame retardant putty prepared by the method of the present invention.

Embodiment 1

[0051] For the production of the main agent, put 3 parts of nano-montmorillonite as a heat-resistant enhancer and 10 parts of active diluent into a high-speed disperser, and after fully dispersed (5 minutes), a coarse suspension is produced and pumped into the grinder Medium grinding to produce a nano-montmorillonite suspension, then put it into the disperser and add other raw materials three times: the first time: add 70 parts of heat-resistant unsaturated polyester resin, 30 parts of silicone resin, with an interval of 5 minutes, the second time Add 4 parts of anti-settling agent for the second time, with an interval of 5 minutes, add 3 parts of special filler, 5 parts of putty performance modifier, 1 part of flame retardant, 5 parts of low shrinkage additive, and 0.1 part of stabilizer for the third time, as a promotion 0.5 part of dimethyl aniline as agent, 0.5 part of dispersant, 4 parts of titanium dioxide, 5 parts of hollow glass microspheres, 3 parts of drier, 0.5 part ...

example 2

[0056] The production of the main agent, 3 parts of nano-montmorillonite, 15 parts of active diluent, the first time: add 75 parts of heat-resistant unsaturated polyester resin, 25 parts of silicone resin, add 6 parts of anti-settling agent for the second time, and add 6 parts of anti-settling agent for the third time Add 4 parts of special filler, 8 parts of putty performance improver, 3 parts of flame retardant, 6 parts of low shrinkage additive, 0.3 part of stabilizer, 0.8 part of dimethylaniline, 1 part of dispersant, 8 parts of titanium dioxide, hollow glass 5 parts of microbeads, 4 parts of drier, 0.8 parts of molybdenum disulfide, 130 parts of talcum powder;

[0057] The preparation of the curing agent, 6 parts of ketone peroxide, 4 parts of curing agent filler, 1.5 parts of oxacridone blue light red and 0.4 parts of polyvinylpyrrolidone;

[0058] For the preparation of the flame retardant putty, the main agent and the curing agent are mixed and prepared at a ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com