A high temperature, high pressure and high turbulence single droplet evaporation experimental device and method thereof

A high-temperature, high-pressure, experimental device technology, applied in the direction of measuring devices, engine testing, machine/structural component testing, etc., can solve problems such as the inability to study the influence of turbulent evaporation on turbulent single droplet evaporation, and achieve uniform heating and high heating efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

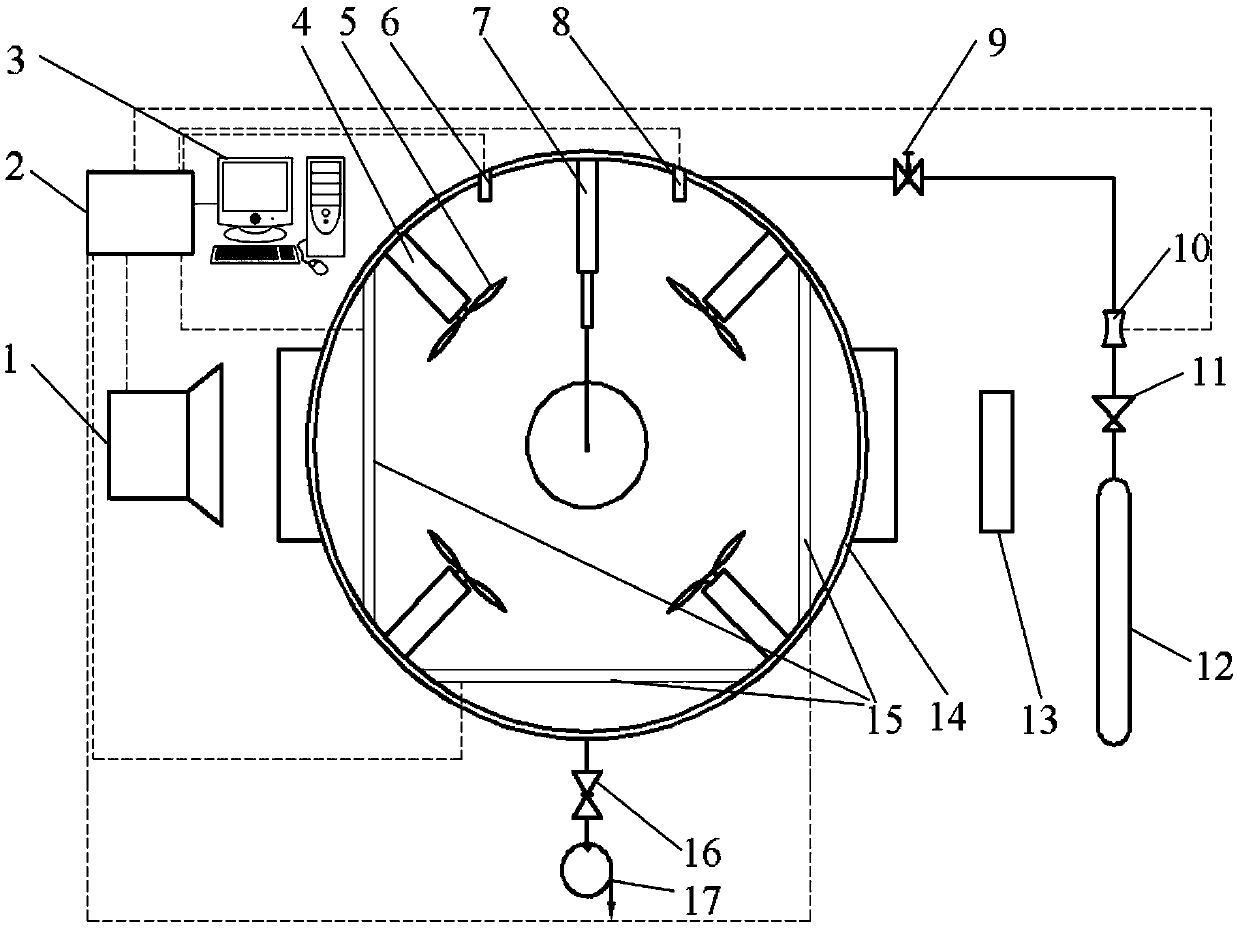

[0028] figure 1 It is a schematic structural diagram of a high-temperature, high-pressure, high-turbulence single-droplet evaporation device described in an embodiment of the present invention. Such as figure 1 As shown, a high-temperature, high-pressure, and high-turbulence single-droplet evaporation device includes: an air supply device, an evaporation constant-volume projectile 14 , a fan 5 , a telescopic droplet suspension device 7 , a control unit 2 and a computer 3 .

[0029] The gas supply device also includes: a pressure reducing valve 11 connected between the high-pressure nitrogen cylinder 12 and the evaporation constant volume projectile 14 , a micro mass flow meter 10 and an inlet valve 9 .

[0030] The high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com