Super-soft, insulated and fireproof mineral cable containing graphene

A technology for mineral insulated and fireproof cables, applied in insulated cables, insulated conductors, bendable cables, etc., can solve the problems of undiscovered graphene and lack of carbon atoms, and achieve strong signal transmission and electrical conductivity, strong fire resistance, Improve the effect of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

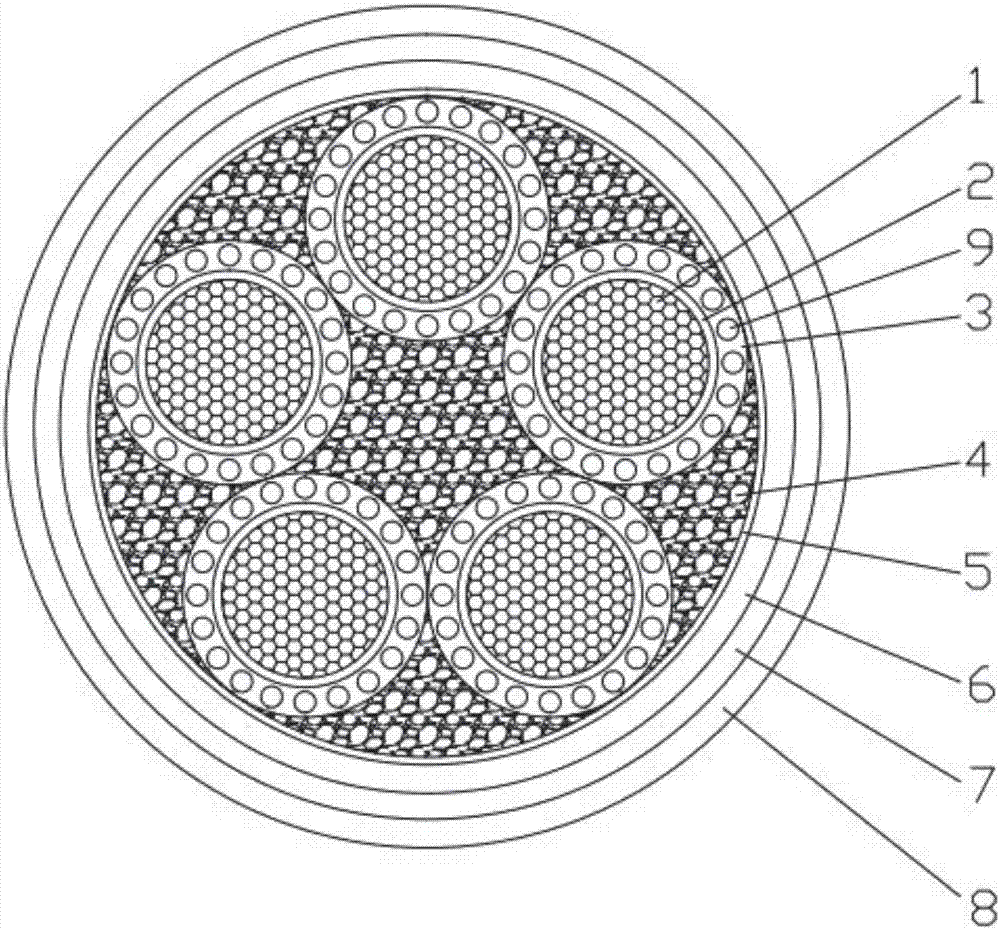

[0033] Please refer to the attached figure 1 , The graphene super-flexible mineral insulated fireproof cable of the present invention includes:

[0034] The sheath 8, the sheath 8 is placed on the outermost layer, the sheath 8 is a halogen-free low-smoke flame-retardant polyolefin sheath; the sheath 8 has strong fire resistance; the halogen-free low-smoke flame-retardant polyolefin sheath does not It is easy to burn, even if it produces very little smoke after burning, the flame retardant material can prevent the fire from expanding;

[0035] Copper tape interlocking armor layer 7, the copper tape interlocking armor layer 7 is placed in the sheath 8; the copper tape interlocking armor layer 7 has the ability to prevent damage, and this layer is a shielding layer; the copper tape interlocking armor The mounting layer is a copper layer or a copper-aluminum alloy layer or an aluminum layer.

[0036] The isolation layer 6, the isolation layer 6 is placed in the coppe...

Example Embodiment

[0042] Example 2:

[0043] A cable core includes a graphene conductor 9, and the graphene conductor 9 includes the following materials by mass:

[0044] Graphene 99%;

[0045] Conductive glue 1%.

[0046] The above two materials of the graphene conductor 9 of the present invention are only the main materials, and it is not limited to only these two materials.

Example Embodiment

[0047] Example 3:

[0048] A method for preparing a cable core, the method comprising the following steps:

[0049] Step 1: Preparation of graphene conductor 9 by mixing 99% by mass of graphene powder and 1% by mass of liquid conductive adhesive 1%, and then preparing the graphene conductor 9 wire body through an extrusion process;

[0050] Step 2: The copper conductor 1 is placed in the synthetic mica-wrapped refractory layer 2 through the outer skin coating technology to form an inner core;

[0051] Step 3: Place the inner core of step 2 in the center of the glue mold. The glue mold is a clamping mold. The graphene conductor 9 wires of step 1 are placed in a ring array in the glue mold. The ceramicized polyolefin insulating layer 3 is prepared in an inverted mold;

[0052] Step 4: After curing, take out the finished product in step 3, which is the cable core.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap