Semiconductor device

A semiconductor, conductive type technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increased switching loss, increased carrier concentration on the emitter side, etc., to achieve reduced switching loss, On-state voltage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

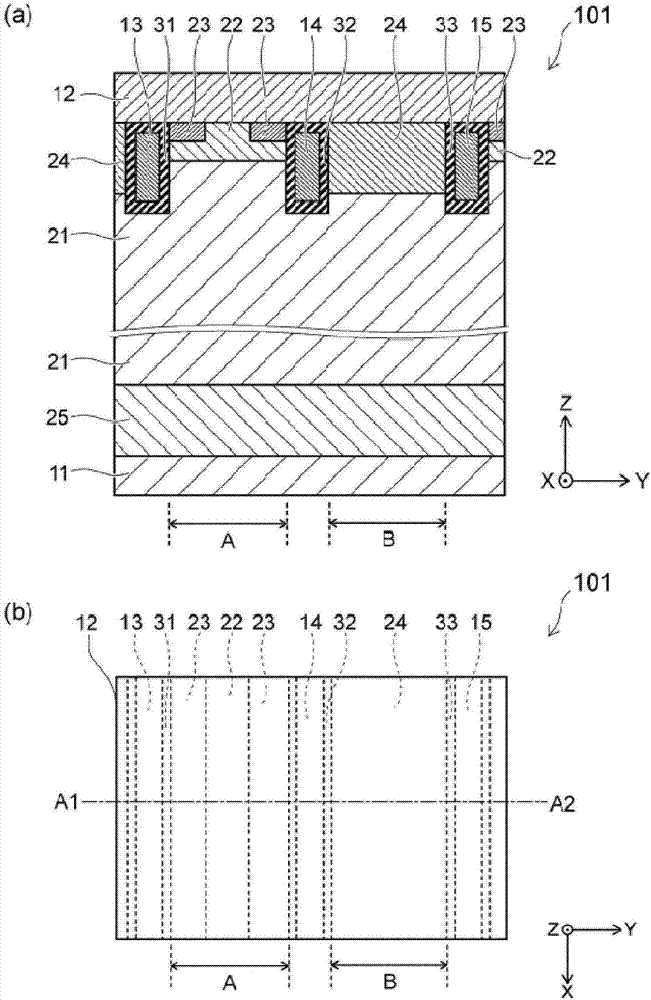

[0033] figure 1 (a) is a schematic cross-sectional view showing the semiconductor device according to the first embodiment. figure 1 (b) is a schematic plan view showing the semiconductor device of the first embodiment. exist figure 1 (a), shows along the figure 1 (b) A cross section of line A1-A2.

[0034] figure 1 The semiconductor device 101 shown in (a) is an IGBT having an upper and lower electrode structure. The semiconductor device 101 includes a first electrode (hereinafter, referred to as a collector electrode 11 , for example), a second electrode (hereinafter, referred to as an emitter electrode 12 , for example), a third electrode 13 , a fourth electrode 14 , a fifth electrode 15 , and a third electrode 13 . 1 semiconductor region (hereinafter, referred to as n - type base region 21), second semiconductor region (hereinafter, referred to as p-type base region 22, for example), third semiconductor region (hereinafter, referred to as n, for example, + type emit...

no. 2 Embodiment approach

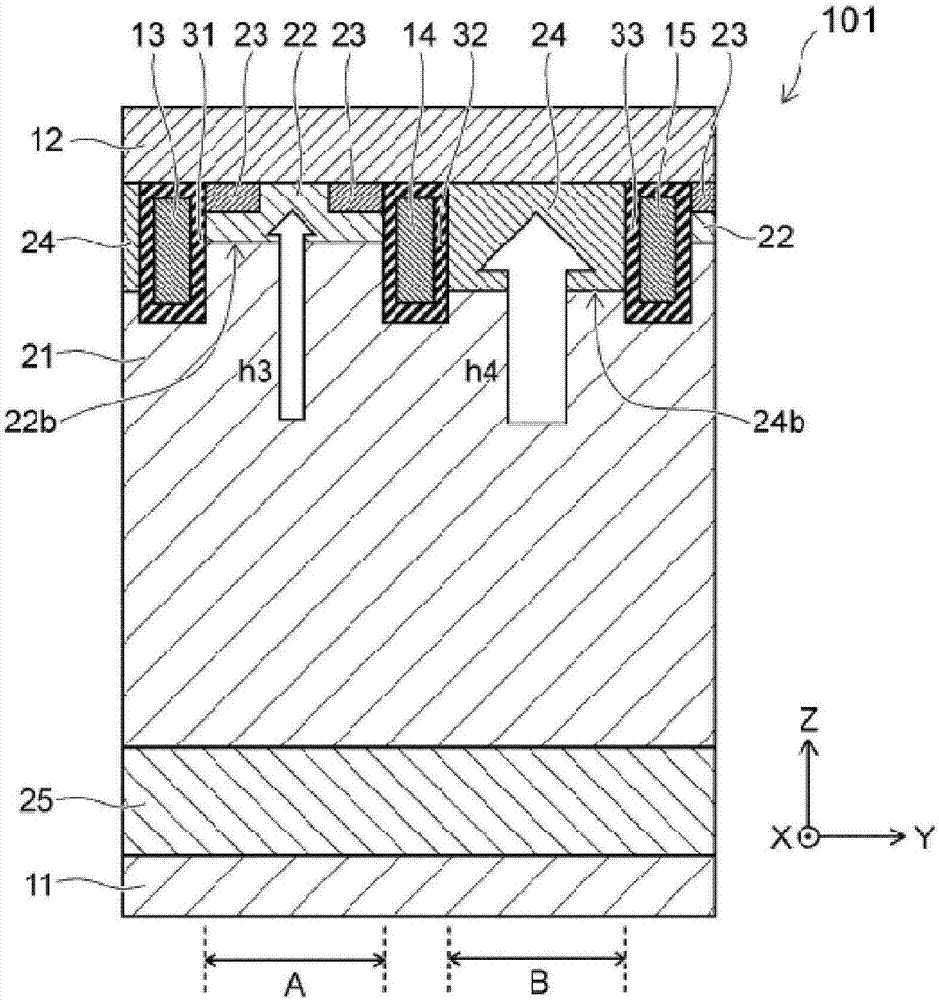

[0078] Figure 4 It is a schematic cross-sectional view showing the semiconductor device of the second embodiment.

[0079] In the semiconductor device 102 , the length L24 of the p-type semiconductor region 24 is longer than the length L22 of the p-type base region 22 in the Y-axis direction. For example, the length of the A region is 1 μm or more and 6 μm or less. The length of the B region is 2 μm or more and 10 μm or less.

[0080] As a result, at the time of turning off, holes are more quickly discharged to the emitter electrode 12 via the wider p-type semiconductor region 24 . As a result, in the semiconductor device 102 , the switching loss at the time of turn-off is further reduced as compared with the semiconductor device 101 .

no. 3 Embodiment approach

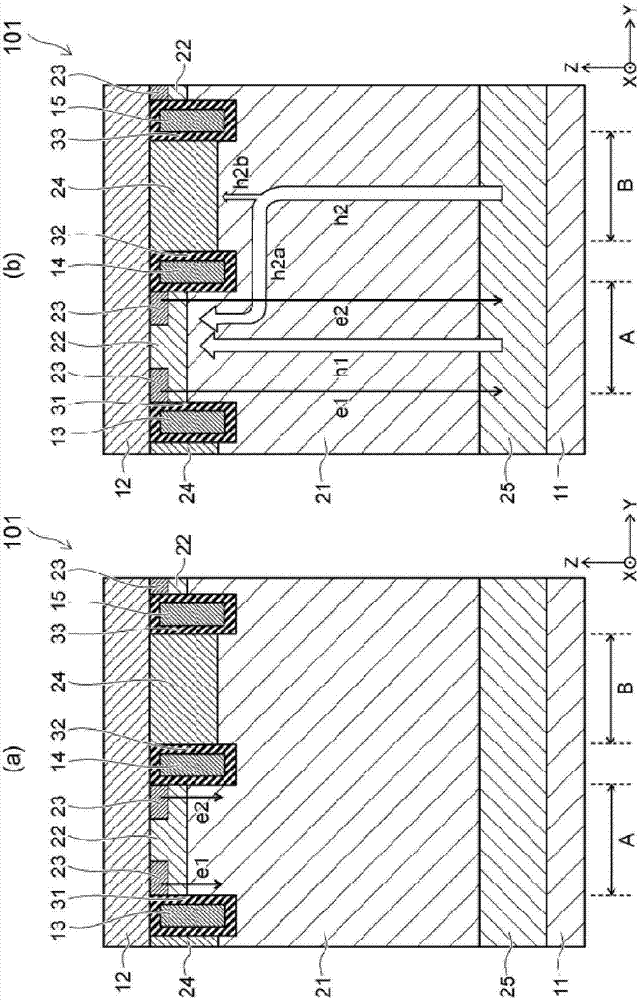

[0082] Figure 5 (a) is a schematic cross-sectional view showing a semiconductor device according to a first example of the third embodiment. Figure 5 (b) is a schematic cross-sectional view showing a semiconductor device according to a second example of the third embodiment.

[0083] exist Figure 5 In the semiconductor device 103A shown in (a), n + The type emitter region 23 is provided on the side of the third electrode 13 and not provided on the side of the fourth electrode 14 . For example, n + The type emitter region 23 is in contact with the first insulating film 31 . n +The type emitter region 23 is not in contact with the second insulating film 32 . In addition, the fourth electrode 14 is electrically connected to the emitter electrode 12 . For example, the fourth electrode 14 is in contact with the emitter electrode 12 .

[0084] In addition, in the Y-axis direction, the p-type base region 22 is arranged in parallel with the p-type semiconductor region 24 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com