A battery pack welding packaging method

A technology for welding packaging and battery packs, applied in battery pack components, circuits, electrical components, etc., can solve problems such as low welding efficiency, many processes, and virtual welding, achieve a high degree of automation, improve welding efficiency, and ensure welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

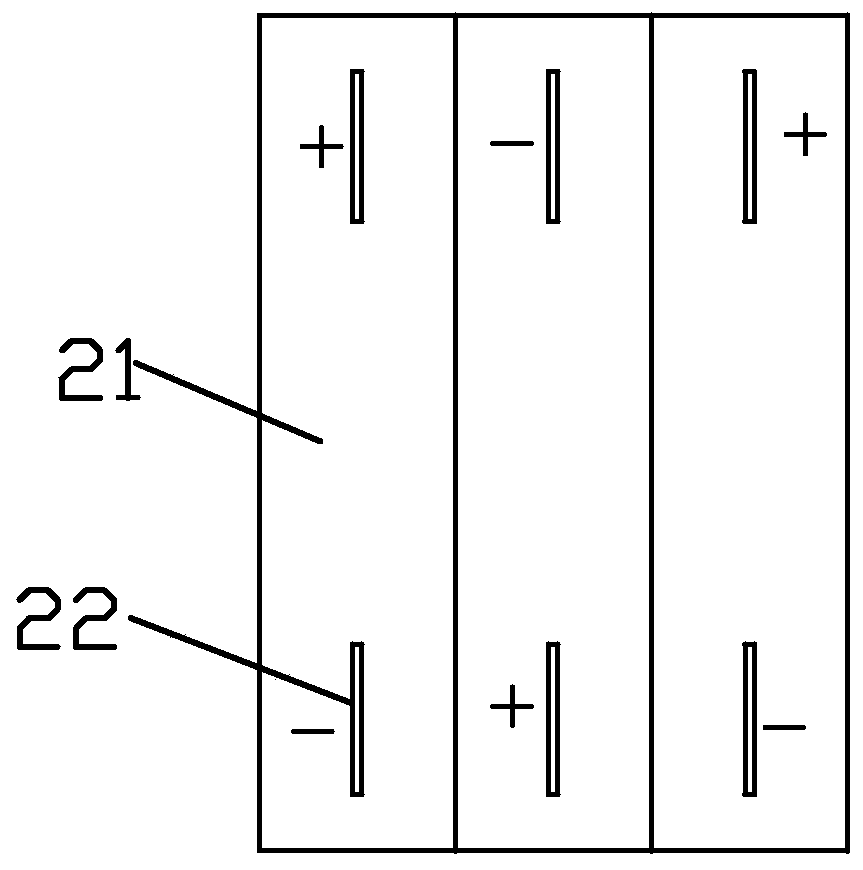

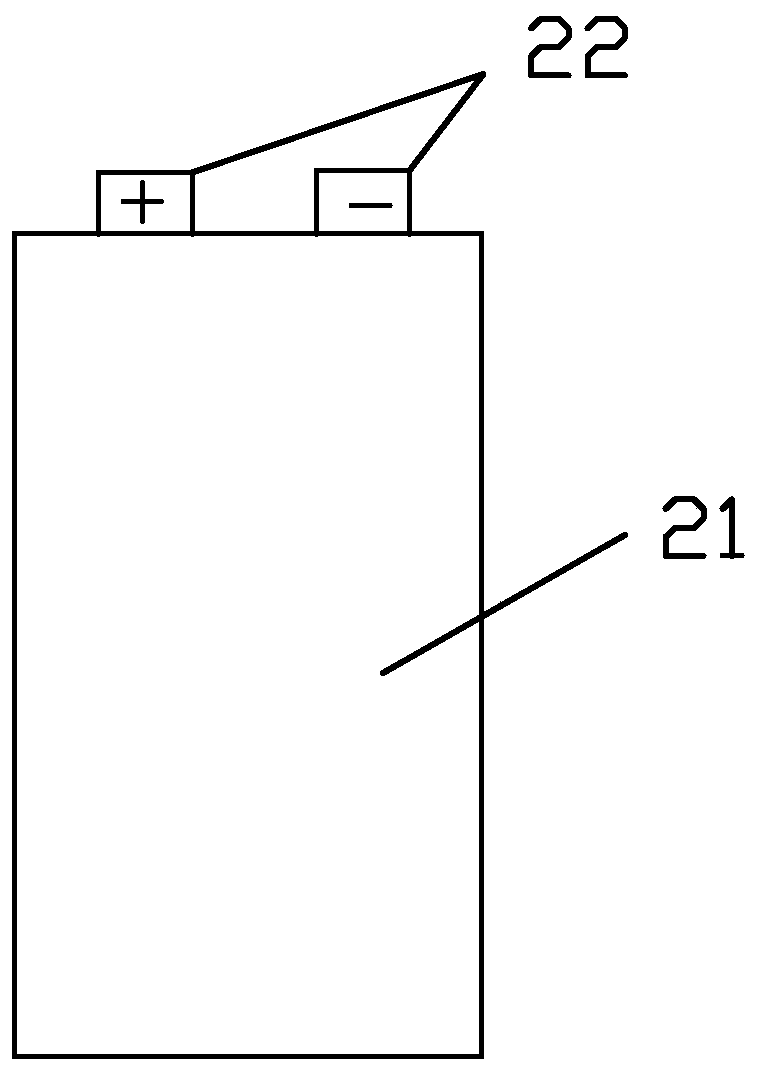

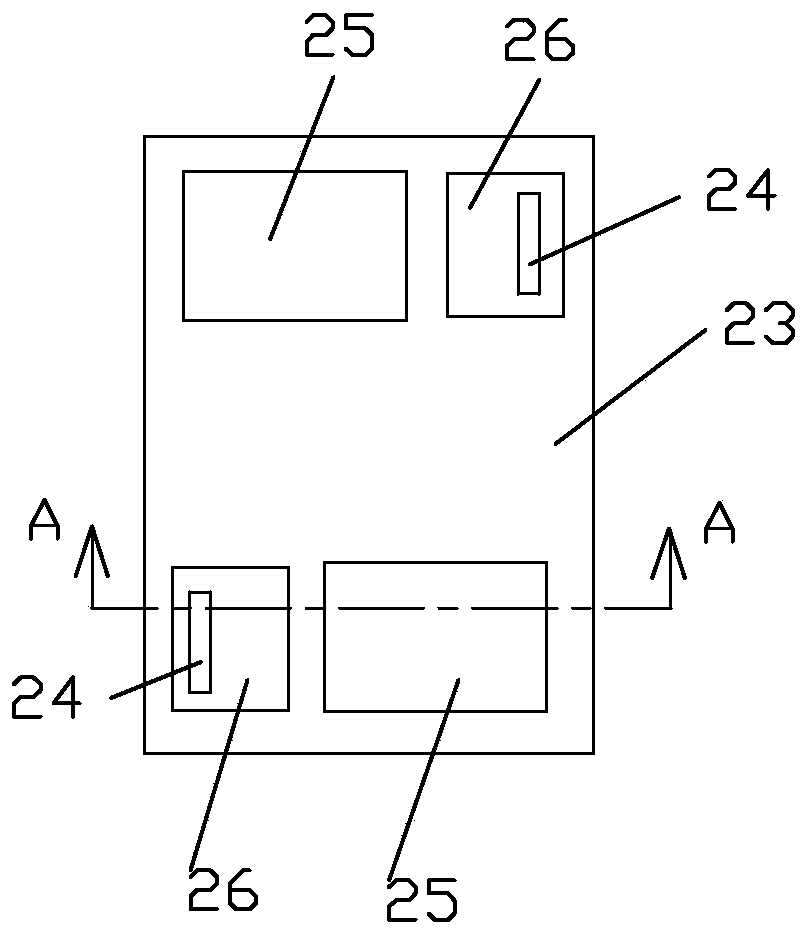

[0112] Embodiment 1: as Figure 3-5 , a battery module based on a mouth-type connector, including a battery pack and a connector; the battery pack is formed by stacking three batteries 21;

[0113] The connecting seat includes a seat body; 4 recesses are arranged on the top of the seat body 23;

[0114] Welding depressions, or called accommodating grooves; here, the two tabs of the battery pack are welded together by soldering or the tabs are welded together with the lead-out end of the battery pack's main electrodes.

[0115] The relationship between the number n of welding depressions and the number N of batteries is: n=N+1; specifically, 2 total power outlets are welded with depressions, and N-1 battery cell electrodes are welded with depressions; (total power supply terminals The welding recesses are used to lead out the general electrodes of the battery pack (ie the overall positive and negative electrodes).

[0116] Among the welding depressions, two welding depression...

Embodiment 2

[0123] Embodiment 2: as Figure 6-8 ; On the basis of Embodiment 1, a battery pack socket 32 for accommodating the battery pack or the end of the battery pack is provided on the upper side of the base body (that is, on the same side as the recessed portion).

Embodiment 3

[0124] Embodiment 3: as Figure 9-13 , On the basis of Embodiment 1, the difference from Embodiment 1 is that a pin 33 is inserted into the bottom of the welding recess of the lead-out end of the general power supply. The pin is connected with a power supply auxiliary plug-in terminal 30 through a wire, which is generally used as a mainboard power supply terminal. The power supply auxiliary plug-in end can be a socket or a plug. way of manufacturing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com