Anti-freezing switch cabinet

A switchgear and cabinet body technology, applied in the field of switchgear, can solve problems such as cracking of the switchgear, freezing of the switchgear, performance change of the switchgear, etc., and achieve the effects of convenient installation and maintenance, high heating efficiency, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

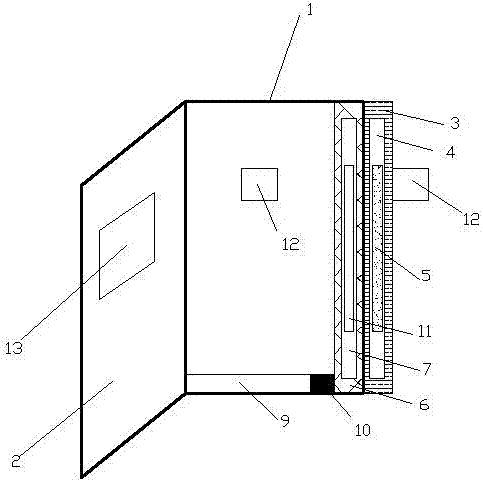

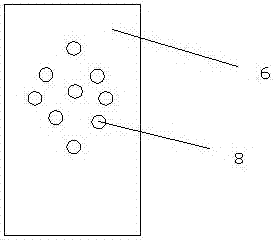

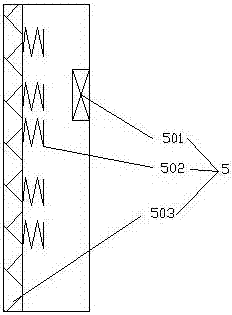

[0029] see figure 1 , figure 2 , image 3 , this embodiment relates to an antifreeze switchgear, comprising a cabinet body 1 and a cabinet door 2, the outer wall of the cabinet body 1 is provided with a thermal insulation board 3, and the thermal insulation board 3 is provided with a heating device accommodating cavity 4, and the heating device accommodating cavity 4. A heating device 5 is provided inside, and the heating device 5 includes a control unit 501, an excitation unit 502 and an induction unit 503. The inner wall of the cabinet body 1 is provided with a heat dissipation layer 6, and the heat dissipation layer 6 is provided with a heat dissipation pipe accommodating cavity 7. The heat dissipation pipe 11 hovers inside the heat dissipation pipe accommodation cavity 7. The heat dissipation layer 6 is provided with a heat dissipation hole 8 connecting the inner cavity of the cabinet body 1 and the heat dissipation pipe accommodation chamber 7. The bottom of the cabinet...

Embodiment 2

[0039] see figure 1 , figure 2 , image 3 , this embodiment relates to an antifreeze switchgear, comprising a cabinet body 1 and a cabinet door 2, the outer wall of the cabinet body 1 is provided with a thermal insulation board 3, and the thermal insulation board 3 is provided with a heating device accommodating cavity 4, and the heating device accommodating cavity 4. A heating device 5 is provided inside, and the heating device 5 includes a control unit 501, an excitation unit 502 and an induction unit 503. The inner wall of the cabinet body 1 is provided with a heat dissipation layer 6, and the heat dissipation layer 6 is provided with a heat dissipation pipe accommodating cavity 7. The heat dissipation pipe 11 hovers inside the heat dissipation pipe accommodation cavity 7. The heat dissipation layer 6 is provided with a heat dissipation hole 8 connecting the inner cavity of the cabinet body 1 and the heat dissipation pipe accommodation chamber 7. The bottom of the cabinet...

Embodiment 3

[0051] see figure 1 , figure 2 , image 3 and Image 6 , this embodiment relates to an antifreeze switchgear, comprising a cabinet body 1 and a cabinet door 2, the outer wall of the cabinet body 1 is provided with a thermal insulation board 3, and the thermal insulation board 3 is provided with a heating device accommodating cavity 4, and the heating device accommodating cavity 4. There is a heating device 5 inside. The heating device 5 includes a control unit 501, an excitation unit 502 and an induction unit 503. The inner wall of the cabinet body 1 is provided with a heat dissipation layer 6, and the heat dissipation layer 6 is provided with a heat dissipation pipe accommodation chamber. 7. The heat dissipation pipe 11 hovers inside the heat dissipation pipe accommodation cavity 7. The heat dissipation layer 6 is provided with a heat dissipation hole 8 connecting the inner cavity of the cabinet body 1 and the heat dissipation pipe accommodation chamber 7. The bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com