Wax injection molding device and casting method for article using wax injection molding device

A technology of injection molding device and wax mold, which is used in casting molding equipment, cores, casting molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

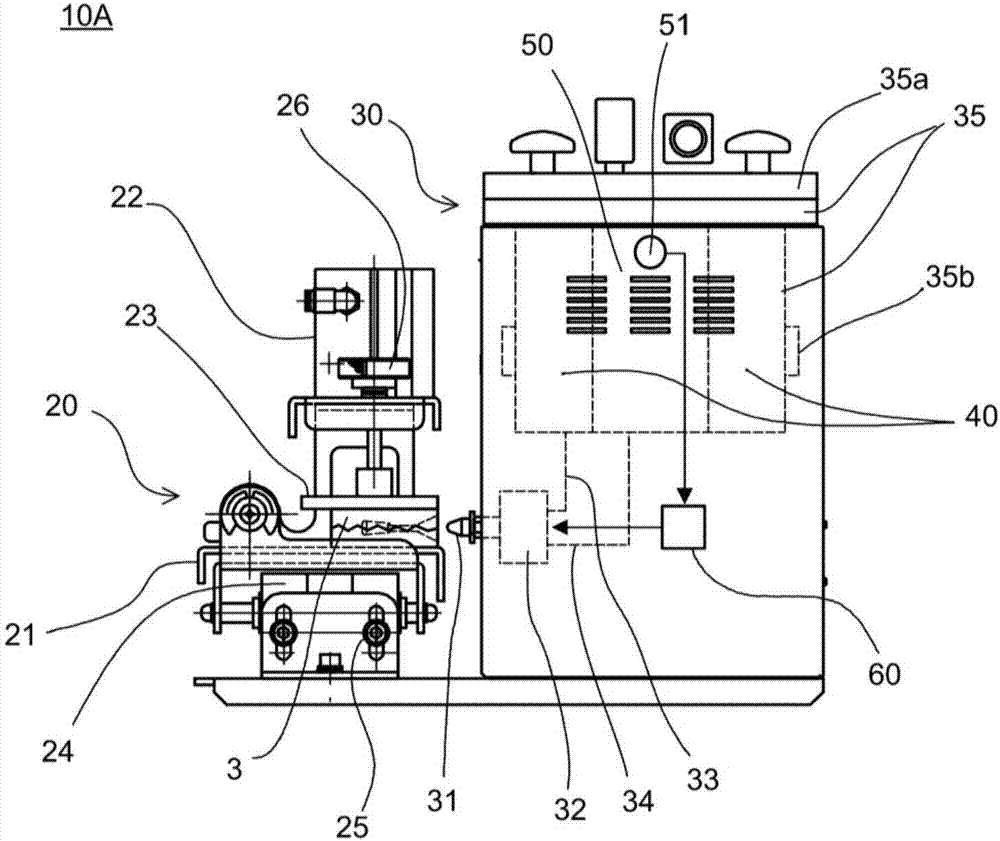

[0127] The wax pattern injection molding apparatus 10A of the present embodiment includes a clamp unit 20 , a wax injection unit 30 , and an operation control unit 60 . The clamp unit 20 and the wax injection unit 30 basically have the same structure as the clamp unit 20 and the wax injection unit 30 of the wax mold injection molding apparatus 10 .

[0128] Figure 4 The vacuum tank 50 of the wax injection unit 30 of this embodiment is shown.

[0129] As shown in the figure, a pressure sensor 51 and a vacuum pump 52 are connected to the vacuum chamber 50 . The pressure sensor 51 is used to measure the pressure (air pressure) inside the vacuum tank 50 . The pressure sensor 51 can be any device, structure, or structure that can measure the pressure inside the vacuum chamber 50 . The pressure sensor 51 can be, for example, a vacuum gauge such as a Pirani vacuum gauge, a MacLeod vacuum gauge, or a liquid column vacuum gauge.

[0130] The injection nozzle 31 is connected to the...

Embodiment approach 1-2

[0172] In Embodiment 1-2, the operation control unit 60 controls wax injection based on the pressure P of the vacuum chamber 50 . In a preferred embodiment, the action control unit 60 controls the time from the start of wax injection (for example, the moment when the switching mechanism 32 is switched from state 2 to state 3) to the end of wax injection (for example, the moment when the switching mechanism 32 is switched from state 3 to state 3). State 1 switching moment) this period (called wax injection time Ti) is controlled. In a particularly preferred embodiment, the operation control unit 60 calculates the cavity volume Vg from the pressure P of the vacuum chamber 50, and determines the wax injection time Ti based on the cavity volume Vg. The operation control unit 60 can switch the mechanism 32 from the state 3 to the state 1 after the elapse of time Ti from the time when the switching mechanism 32 is switched from the state 2 to the state 3 .

[0173] The case where t...

no. 2 Embodiment approach

[0185] The vacuum valve 54 of the wax pattern injection molding apparatus 10A can be omitted. Alternatively, the wax injection molding apparatus 10A may be used without opening and closing control with the vacuum valve 54 opened. This embodiment is referred to as a second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com