Circuit assembly for high-voltage tests and high-voltage testing system

A technology of circuit device and high voltage test, which is applied in the direction of test circuit, measuring device, transformer test, etc., can solve the problem of high cost and achieve the effect of eliminating cost and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

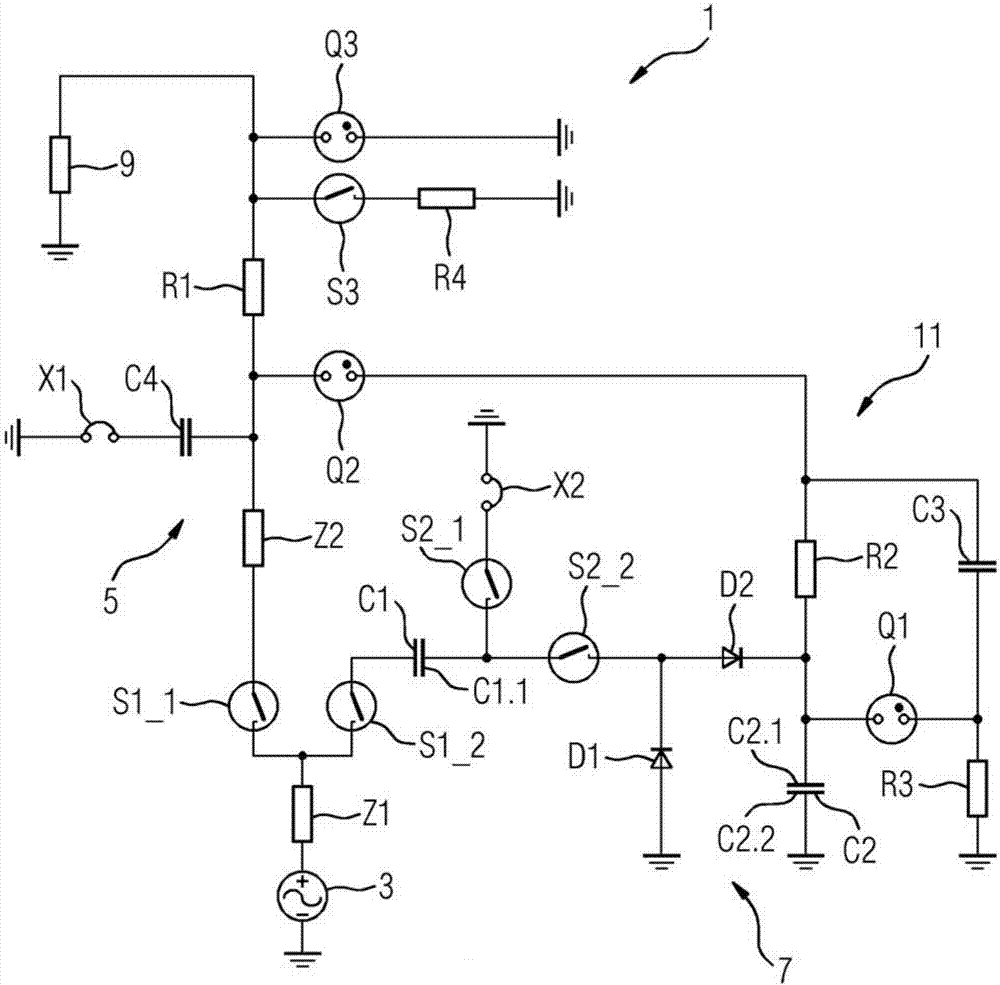

[0038] figure 1 shown in figure 1 A circuit diagram of a circuit arrangement 1 of a high-voltage test device 13 for a high-voltage test, not shown in FIG. 2 , wherein, as described below, the various components of the circuit arrangement 1 shown are optional.

[0039] The circuit arrangement 1 comprises an AC voltage source 3, a first circuit branch 5 electrically connectable to the AC voltage source 3 via a first switch S1_1 and a second circuit branch 7 electrically connectable to the AC voltage source 3 via a second switch S1_2 . The switches S1_1 and S1_2 can also be realized together as a transfer switch.

[0040] The AC voltage source 3 preferably includes a variable transformer for generating relatively high AC voltages, for example with an effective value of up to 750 kV.

[0041] An alternating voltage can be applied to the test piece 9 by means of the first circuit branch 5 .

[0042] For performing alternating current partial discharge measurements, the first ci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap