Topping screen printing machine

A screen printing machine and color registration technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of high maintenance frequency, low work efficiency, poor operation stability, etc., to improve work efficiency and The stability of work, the extension of maintenance cycle, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

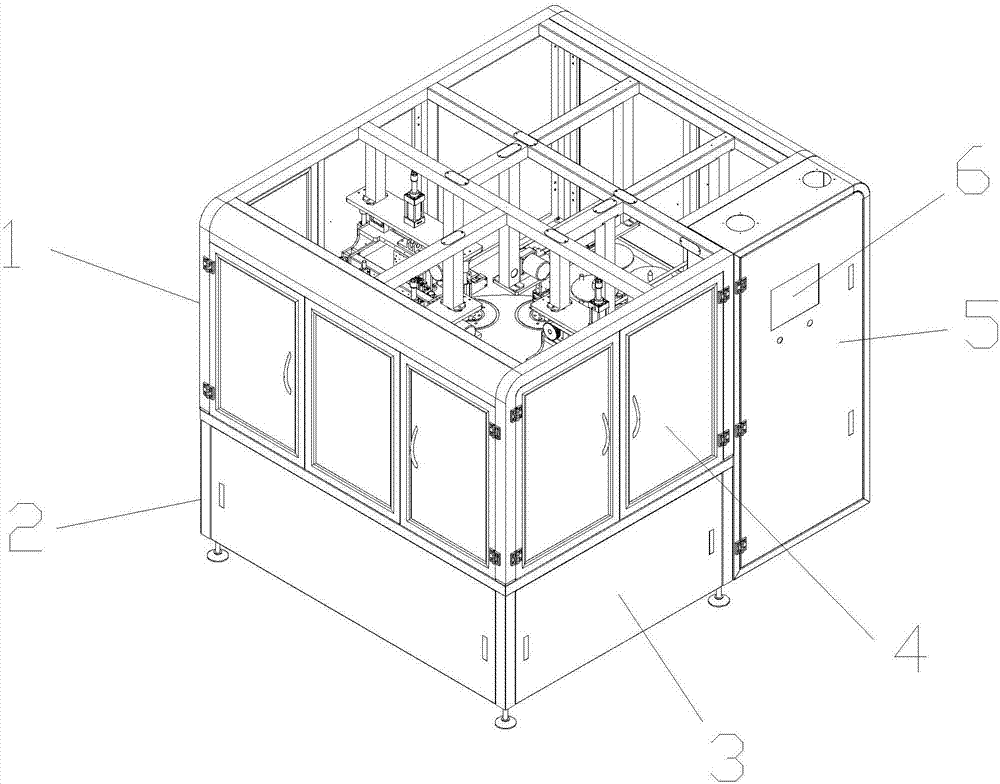

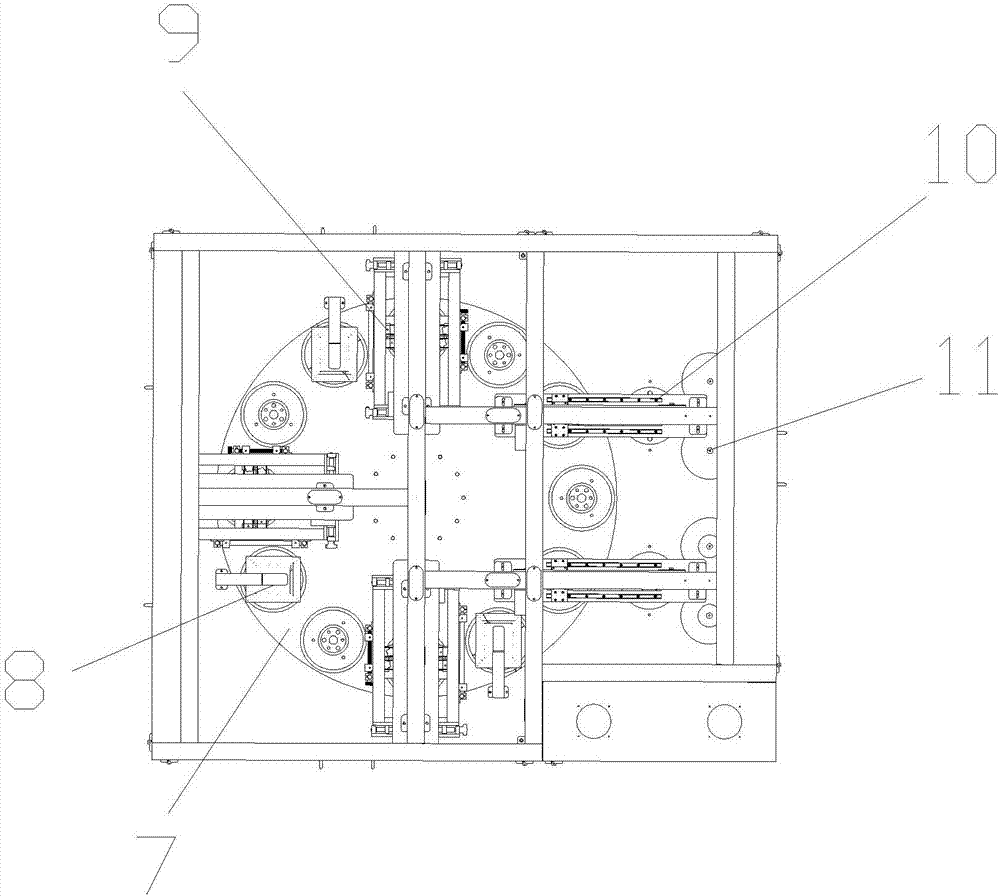

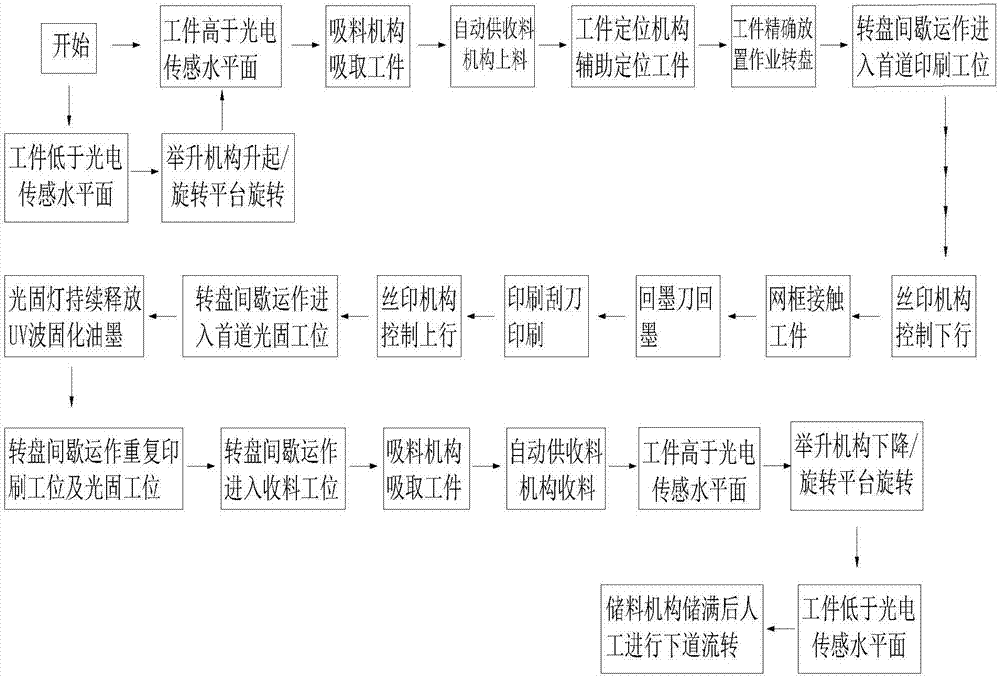

[0019] see Figure 1-Figure 3 , the present invention provides a scheme of a new computer information processing device for a color screen printing machine: its structure includes a protective cover 1, a bottom frame 2, a bottom inspection door 3, a working observation window 4, an electric box 5, a touch screen 6, Operation turntable 7, light-fixing mechanism 8, silk screen mechanism 9, automatic feeding mechanism 10, storage and discharge mechanism 11, the lower part of the protective cover 1 is fixed by welding and the bottom frame 2, and the protective cover 1 is provided with a working Observation window 4, the working observation window 4 is movably connected with the protective cover 1 through a hinge, the front, rear, left, and right sides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap