Strengthened arc-blended-plate-structure supporting leg

A reinforced, reinforced plate technology, used in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of limited static load capacity and small bearing area of the outriggers, and can increase the welding range and increase the static load. Ability, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

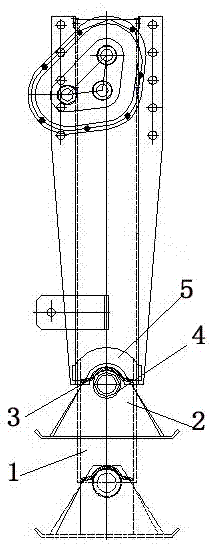

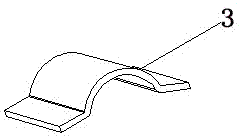

[0016] The present invention includes an inner tube 1 and a base 2 arranged at the lower part of the inner tube 1, and the inner tube 1 and the base 2 are connected through an arc-shaped bent plate 3;

[0017] The upper part of the curved curved plate 3 is connected to the inner tube 1, and the lower part of the curved curved plate 3 is connected to the base 2 through the connecting pipe 4 fixed on the base 2;

[0018] The middle part of the lower surface of the arc-shaped bent plate 3 is a concave arc corresponding to the outer surface contour of the connecting pipe 4 , and the two sides are transverse parts connected with the inner pipe 1 .

[0019] The bottom of the inner tube 1 is provided with a reinforcing plate 5 fixedly connected to the inner tube 1;

[0020] The arc-shaped bent plate 3 is fixedly connected to the reinforcing plate 5 , and the contour of the lower surface of the reinforcing plate 5 is set correspondingly to the contour of the upper surface of the arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com