High-strength concrete plate and forming process thereof

A concrete and high-strength technology, applied in the field of building materials, can solve problems such as insufficient strength and insufficient compactness of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

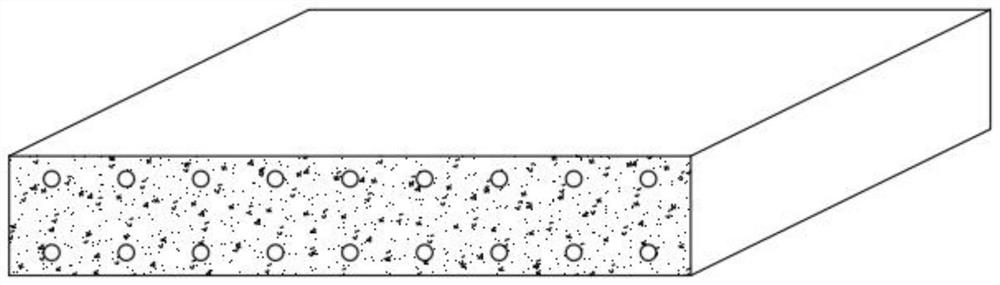

[0041] see figure 1 , a high-strength concrete plate, including the following raw materials in parts by weight: 150 parts of ordinary portland cement, 50 parts of mineral powder, 50 parts of fly ash, 400 parts of crushed stone, 200 parts of sand, and 100 parts of glass beads , 180 parts of water, 4 parts of polycarboxylate superplasticizer, 1 part of anti-crack fiber and 150 parts of thermally expandable microspheres.

[0042] The mineral powder is S95 grade mineral powder with a density of 2880Kg / m3.

[0043] The fly ash is class F class II fly ash with a density of 2150Kg / m3.

[0044] The crushed stone is 5-20mm continuous graded impact crushed stone, the needle flake content is not more than 5%, the mud content is not more than 0.5%, and the mud block content is not more than 0.2%. The parent rock is basalt or limestone, and the parent rock is compressive. The strength is not less than 130MPa.

[0045] The sand is zone II sand with a fineness modulus of 2.7-3.0, MB value i...

Embodiment 2

[0057] A high-strength concrete plate, comprising the following raw materials in parts by weight: 175 parts of ordinary portland cement, 65 parts of mineral powder, 65 parts of fly ash, 450 parts of gravel, 225 parts of sand, 110 parts of glass beads, 190 parts of water, 6 parts of polycarboxylate superplasticizer, 2 parts of anti-split fiber and 175 parts of heat-expandable microspheres.

[0058] The rest are consistent with Example 1.

Embodiment 3

[0060] A high-strength concrete plate, comprising the following raw materials in parts by weight: 200 parts of ordinary portland cement, 80 parts of mineral powder, 80 parts of fly ash, 500 parts of gravel, 250 parts of sand, 120 parts of glass beads, 200 parts of water, 8 parts of polycarboxylate superplasticizer, 3 parts of anti-crack fiber and 200 parts of thermally expandable microspheres.

[0061] The rest are consistent with Example 1.

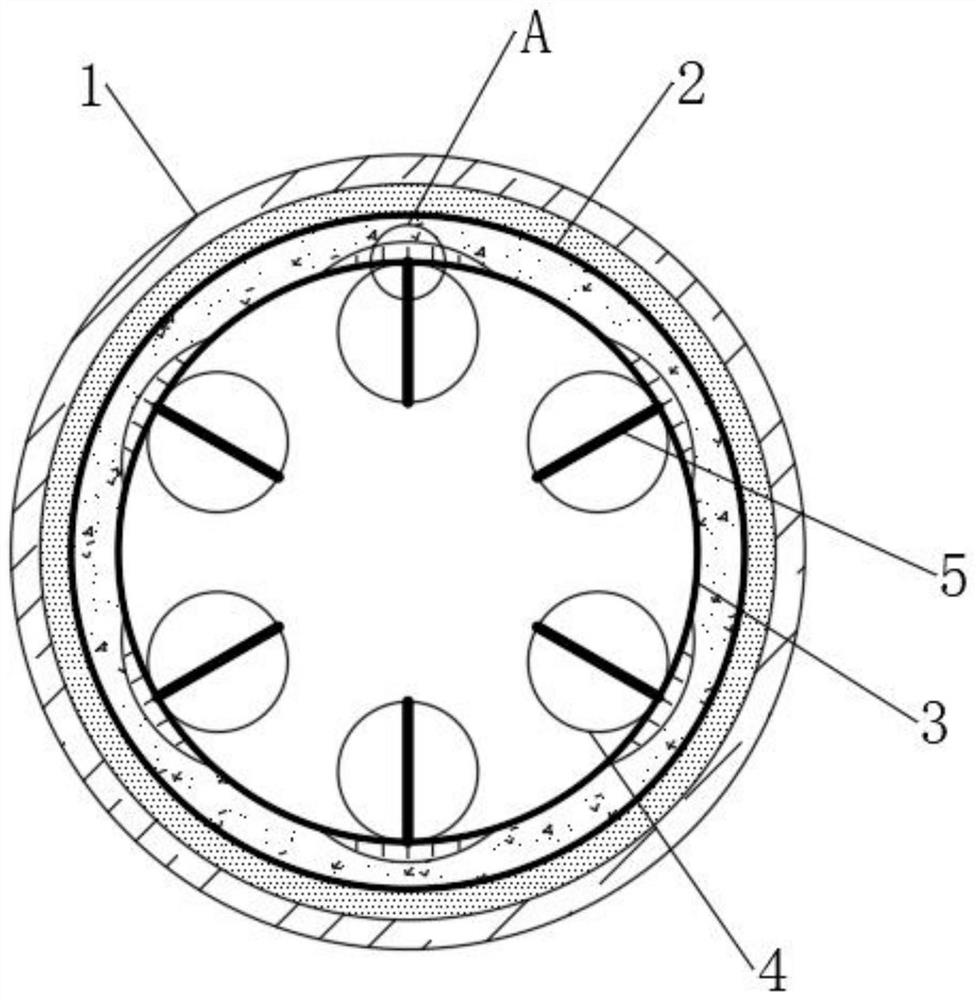

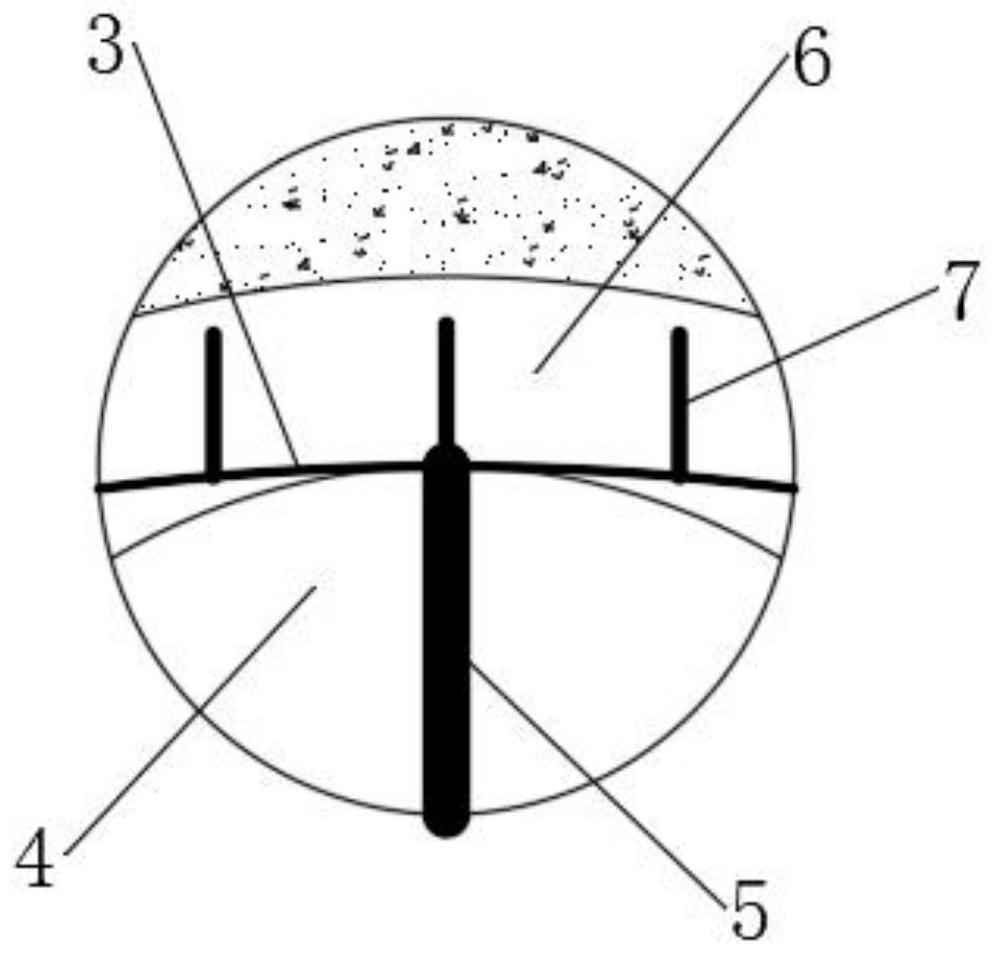

[0062] see Figure 5 , the present invention can mix heat-expandable microspheres in the raw material before concrete molding, and directly embed them in the plate in a pre-embedded manner. When solidifying and forming in the mold, firstly, the method of external pressure is used, and secondly, the thermal expansion is triggered by heating. The expansion action of the microspheres inside the concrete forms multi-point extrusion inside, and the external pressure can effectively improve the compactness of the concrete. Peeling, at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com