Preparation method of nano titanium rare-earth composite catalyst and application of catalyst in synthesis of polyesters and copolyesters.

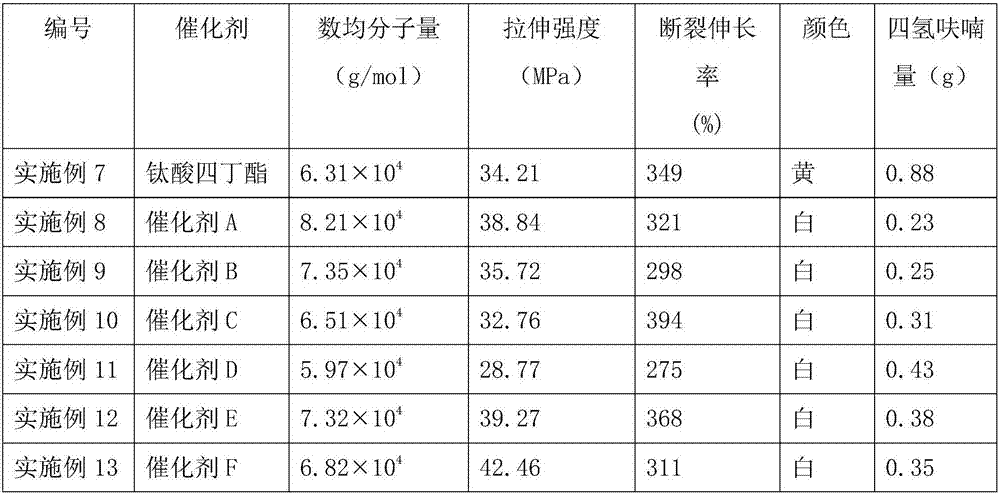

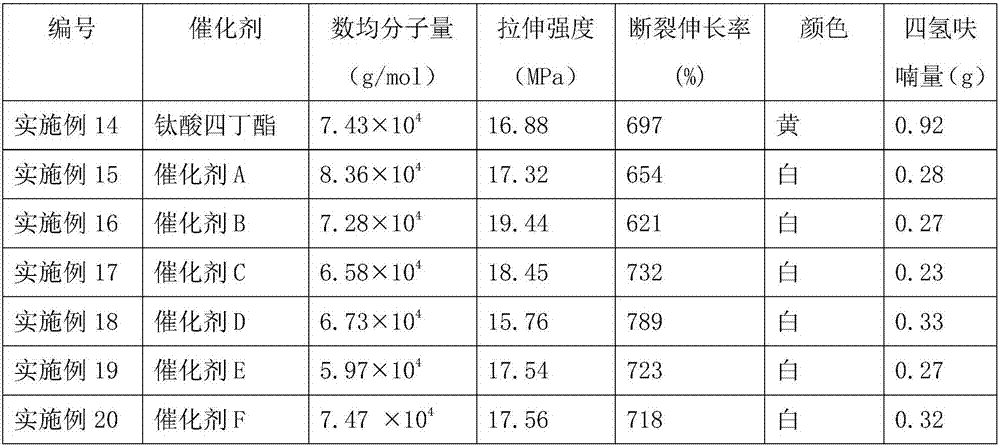

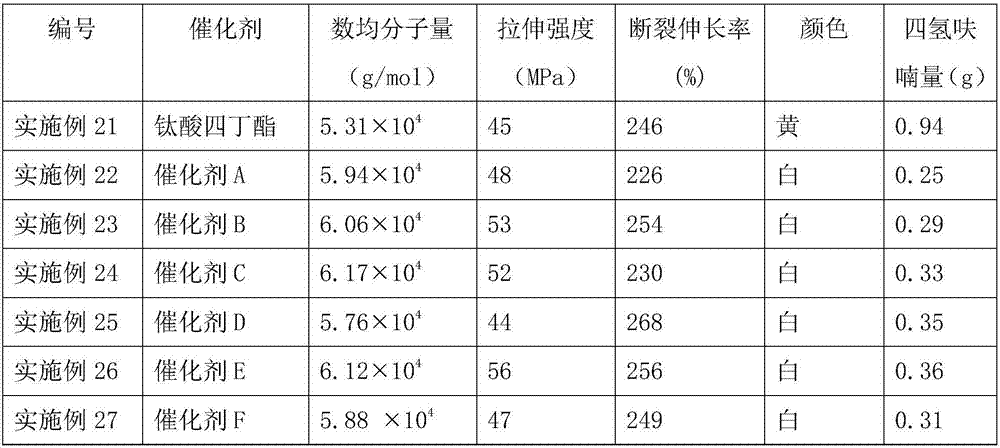

A technology of rare earth compounding and catalyst, which is applied in the field of preparation of nano-titanium rare earth compound catalyst, which can solve the problems of low catalyst reaction efficiency, high by-products, yellow color, etc., and achieve the effect of stable reaction, low carboxyl terminal group and low THF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0035] Embodiment 1-6: the synthesis of nano titanium series rare earth composite catalyst

Embodiment 1

[0037] Add 50g of butanediol into the three-necked flask, add tetrabutyl titanate (0.1mol), nano-silicon dioxide (0.01mol), stir and mix evenly, and slowly mix the lactic acid solution (0.3mol) under stirring (50rpm / min) Add it dropwise to the mixture in the three-necked flask, and control the temperature at 50°C until the lactic acid drops completely. , heat up to 80°C until there is no distillate, add magnesium chloride (0.01mol) and dysprosium acetate (0.02mol), continue to stir and control the temperature to 90°C for 2-8 hours, remove small molecules, and obtain nano-titanium rare earth composite Catalyst A.

Embodiment 2

[0039] In the there-necked flask, add 50g absolute ethanol, add tetraethyl titanate (0.1mol), nano-alumina (0.02mol), stir and mix evenly, under stirring (50rpm / min) citric acid-ethanol solution ( 0.3mol) was slowly added dropwise to the mixture in the three-necked flask, and the temperature was controlled to 50° C. to react for 1 to 4 hours until the citric acid-ethanol solution was added dropwise. Then add sodium stearate (0.02mol) and neodymium stearate (0.02mol), heat up to 100°C and react for 2-8 hours, remove small molecules, and obtain nano-titanium series rare earth composite catalyst B.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap