Double-surface adhesion sheet, display member and manufacturing method of display member

An adhesive sheet and display technology, applied in the directions of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as step difference and light reflection loss, and achieve the effect of excellent step followability and good processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] (1) Preparation of a laminate having a first adhesive layer or a second adhesive layer

[0183] (1-1) Preparation of (meth)acrylate polymer (A)

[0184] 65 parts by mass of 2-ethylhexyl acrylate, 5 parts by mass of N-acryloylmorpholine, 15 parts by mass of isobornyl acrylate, and 15 parts by mass of 2-hydroxyethyl acrylate were copolymerized to prepare (methyl ) acrylate polymer (A). When the molecular weight of this (meth)acrylate polymer (A) was measured by the method mentioned later, the weight average molecular weight (Mw) was 500,000.

[0185] (1-2) Preparation of adhesive composition P

[0186] 100 parts by mass of the (meth)acrylate polymer (A) obtained in the above step (1-1) (value in terms of solid content; the same applies hereinafter), 5 parts by mass of the active energy ray-curable compound (B) ε-caprolactone-modified tris(2-acryloyloxyethyl)isocyanurate (manufactured by Shin Nakamura Chemical Co., Ltd., product name "NK ESTER A-9300-1CL"), 0.15 parts b...

Embodiment 2

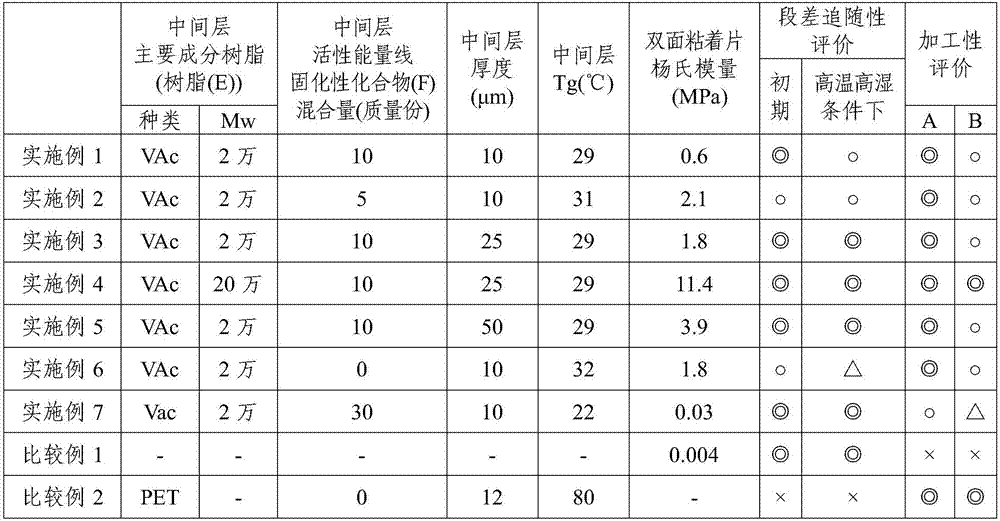

[0208] A resin composition was prepared in the same manner as in Example 1 except that the compounding amount of the active energy ray-curable compound (F) was changed to 5 parts by mass and the compounding amount of the photopolymerization initiator (G) was changed to 0.5 parts by mass. Q coating solution to produce the third laminated body. Except having used this 3rd laminated body, it carried out similarly to Example 1, and produced the double-sided adhesive sheet with a release sheet.

Embodiment 3

[0210] A double-sided adhesive sheet with a release sheet was produced in the same manner as in Example 1 except that the thickness of the intermediate layer was changed to 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com