Pressure-sensitive adhesive composition, pressure-sensitive adhesive, pressure-sensitive adhesive sheet, and display body

A technology of pressure-sensitive adhesive sheets and pressure-sensitive adhesives, applied in the direction of amide/imide polymer adhesives, ester copolymer adhesives, adhesive types, etc., can solve light reflection loss, Existence and other problems, to achieve the effect of dielectric constant suppression, excellent resistance to foaming, excellent resistance to heat and humidity whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] 2. Preparation of pressure-sensitive adhesive composition

[0117] The pressure-sensitive adhesive composition P can be prepared by preparing a (meth)acrylate polymer (A), and combining the obtained (meth)acrylate polymer (A), active energy ray curable Component (C), if necessary, crosslinking agent (B), photopolymerization initiator (D), and additives are mixed.

[0118] The (meth)acrylate polymer (A) can be produced by polymerizing a mixture of monomers constituting the polymer by a normal radical polymerization method. It is preferable to perform polymerization of a (meth)acrylate polymer (A) by the solution polymerization method using a polymerization initiator as needed. Examples of the polymerization solvent include ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, and the like, and two or more of them may be used in combination.

[0119] As a polymerization initiator, an azo compound, an organic peroxide, etc. are ...

manufacture example

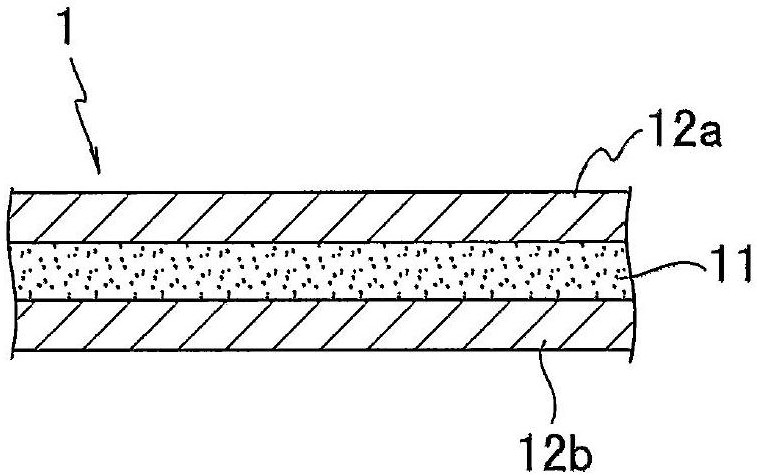

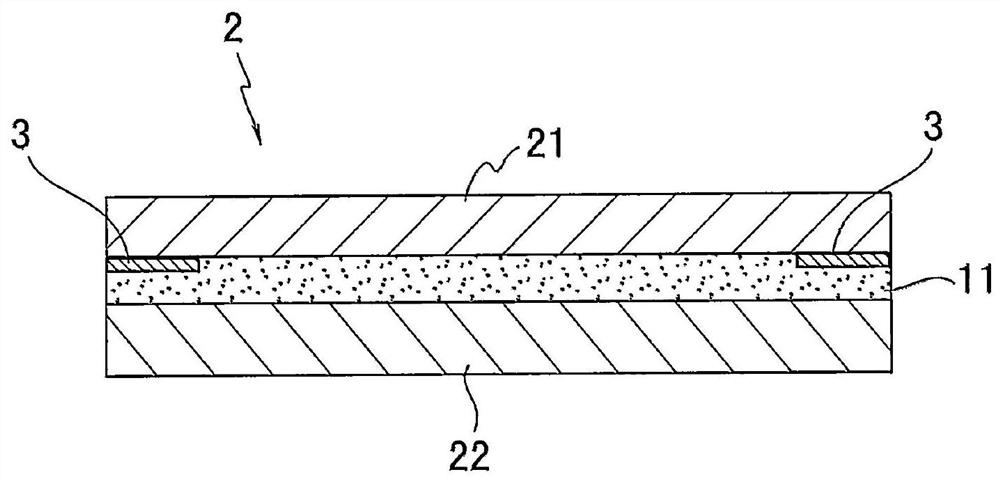

[0161] As another production example of the pressure-sensitive adhesive sheet 1, the above-mentioned coating solution of the pressure-sensitive adhesive composition P is applied to the release surface of one release sheet 12a, and heat treatment is performed to combine the pressure-sensitive adhesive properties. The substance P is thermally cross-linked to form a coating layer, and the peeling sheet 12a with the coating layer is obtained. In addition, the coating liquid of the above-mentioned pressure-sensitive adhesive composition P is coated on the release surface of the other release sheet 12b, and heat treatment is performed to thermally crosslink the pressure-sensitive adhesive composition P to form a coating layer. , to obtain a release sheet 12b with a coating layer. Next, the peeling sheet 12a with a coating layer and the peeling sheet 12b with a coating layer are bonded together so that both coating layers may contact each other. When a curing period is required, the...

Embodiment 1

[0201] 1. Preparation of (meth)acrylate polymer (A)

[0202] 60 parts by mass of 2-ethylhexyl acrylate, 5 parts by mass of 4-acryloylmorpholine, 15 parts by mass of isobornyl acrylate, 5 parts by mass of N-vinylacetamide, and 2-hydroxyl acrylate by solution polymerization 15 parts by mass of ethyl ester were copolymerized to prepare a (meth)acrylate polymer (A). When the molecular weight of this (meth)acrylate polymer (A) was measured using the method mentioned later, it was 500,000 in weight average molecular weight (Mw).

[0203] 2. Preparation of pressure-sensitive adhesive composition

[0204] 100 parts by mass of the (meth)acrylate polymer (A) obtained in the above step 1 (value in terms of solid content; the same applies below), and trimethylolpropane-modified toluene as a crosslinking agent (B) 0.15 parts by mass of diisocyanate (manufactured by TOYOCHEM CO., LTD., product name "BHS8515"), ε-caprolactone-modified tris(2-acryloyloxyethyl) isocyanate as active energy ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com