Energy-saving type emulsified asphalt production device

A technology for emulsified asphalt and production equipment, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, and the petroleum industry. It can solve the problems of waste of water resources and low production efficiency, and achieve energy saving and small footprint. , the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

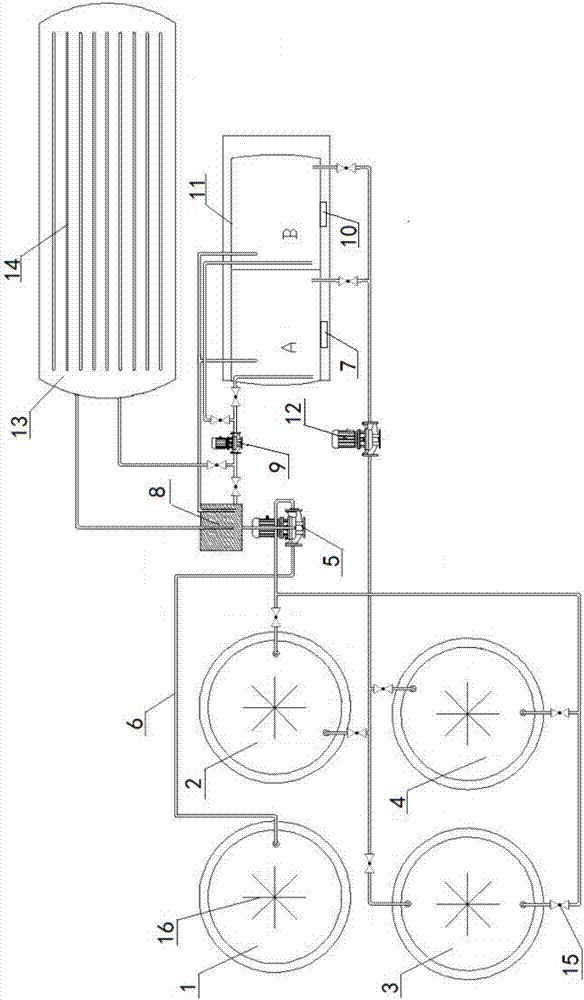

[0029] The present invention will be further described in detail below with reference to the accompanying drawings.

[0030] like figure 1 As shown, the energy-saving emulsified asphalt production device of the present invention mainly includes: asphalt tank 1, soap liquid tank one 2, soap liquid tank two 3, soap liquid tank three 4, emulsification mill 5, multiple conveying pipes 6, temperature Monitoring device one 7, heat exchanger 8, water pump one 9, temperature monitoring device two 10, cooling water tank 11, water pump two 12, finished product tank 13, finished product tank cooling water coil 14, multiple valves 15, four agitators 16.

[0031] The size configuration of the soap tank and the cooling water tank 11: the three soap tanks are all 10T vertical tanks, and the cooling water tank 11 is a 40T horizontal tank, that is, the volume of the cooling water tank is four times that of the soap tank.

[0032] An agitator 16 is respectively provided in the asphalt tank 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap