A kind of metallographic corrosion solution and metallographic corrosion method of zirconium-based alloy

A zirconium-based alloy and metallographic corrosion technology, which is applied in the field of zirconium-based alloy metallographic corrosion solution and metallographic corrosion, can solve the problems of low corrosion efficiency of zirconium-based alloy, poor metallographic sample effect, etc. The effect of high corrosion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

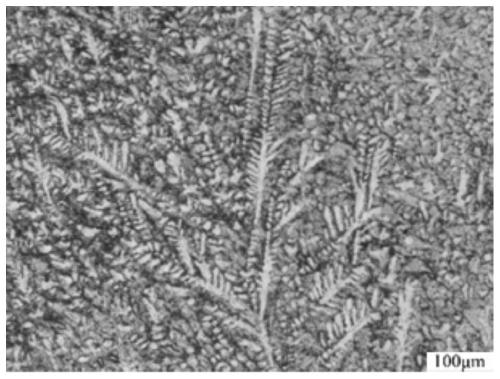

Embodiment 1

[0057] (1) Use a 100ml graduated cylinder to measure 80ml of deionized water and put it in a plastic beaker, use a 10ml plastic graduated cylinder to measure 5ml of hydrofluoric acid, and use a 10ml glass graduated cylinder to measure 5ml of sulfuric acid and 10ml of nitric acid respectively, and the measured hydrofluoric acid , sulfuric acid and nitric acid were poured into a beaker filled with deionized water, and stirred for 30 seconds until uniform, to obtain zirconium-based alloy metallographic etching solution A1.

[0058] (2) Completely immerse the ground and polished zirconium-based alloy in the zirconium-based alloy metallographic corrosion solution A1 obtained in step (1), and take out the zirconium-based alloy after soaking for 30 seconds.

[0059] (3) Rinse the surface of the zirconium-based alloy taken out in step (2) with deionized water for 40 seconds, dry it, and then wipe the surface of the sample with absorbent cotton with alcohol to obtain a zirconium-based a...

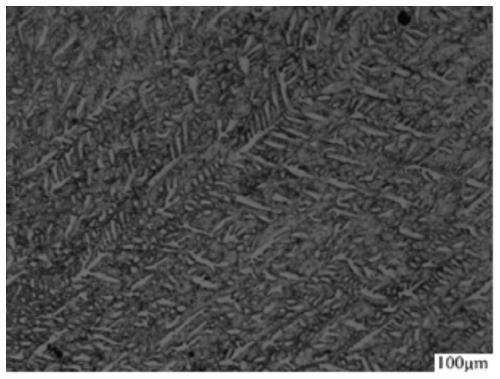

Embodiment 2

[0062] (1) Measure 60ml of deionized water with a 100ml graduated cylinder and place it in a plastic beaker, measure 10ml of hydrofluoric acid with a 10ml plastic graduated cylinder, measure 10ml of sulfuric acid with a 10ml glass graduated cylinder, and measure 20ml of nitric acid with a 25ml glass graduated cylinder. Measured hydrofluoric acid, sulfuric acid and nitric acid were poured into a beaker filled with deionized water, and stirred for 30 seconds until uniform, to obtain a zirconium-based alloy metallographic corrosion solution A2.

[0063] (2) Completely immerse the ground and polished zirconium-based alloy in the zirconium-based alloy metallographic corrosion solution A2 obtained in step (1), and take out the zirconium-based alloy after soaking for 30 seconds.

[0064] (3) Rinse the surface of the zirconium-based alloy taken out in step (2) with deionized water for 40 seconds, dry it, and then wipe the surface of the sample with absorbent cotton with alcohol to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com