High-performance curing agent and preparation method thereof and application of high-performance curing agent in epoxy anticorrosive coating material

A technology of epoxy anti-corrosion coatings and curing agents, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of less inorganic powder and organic matrix, and achieve improved water resistance, reinforced defoaming, Effect of improving mechanical properties and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

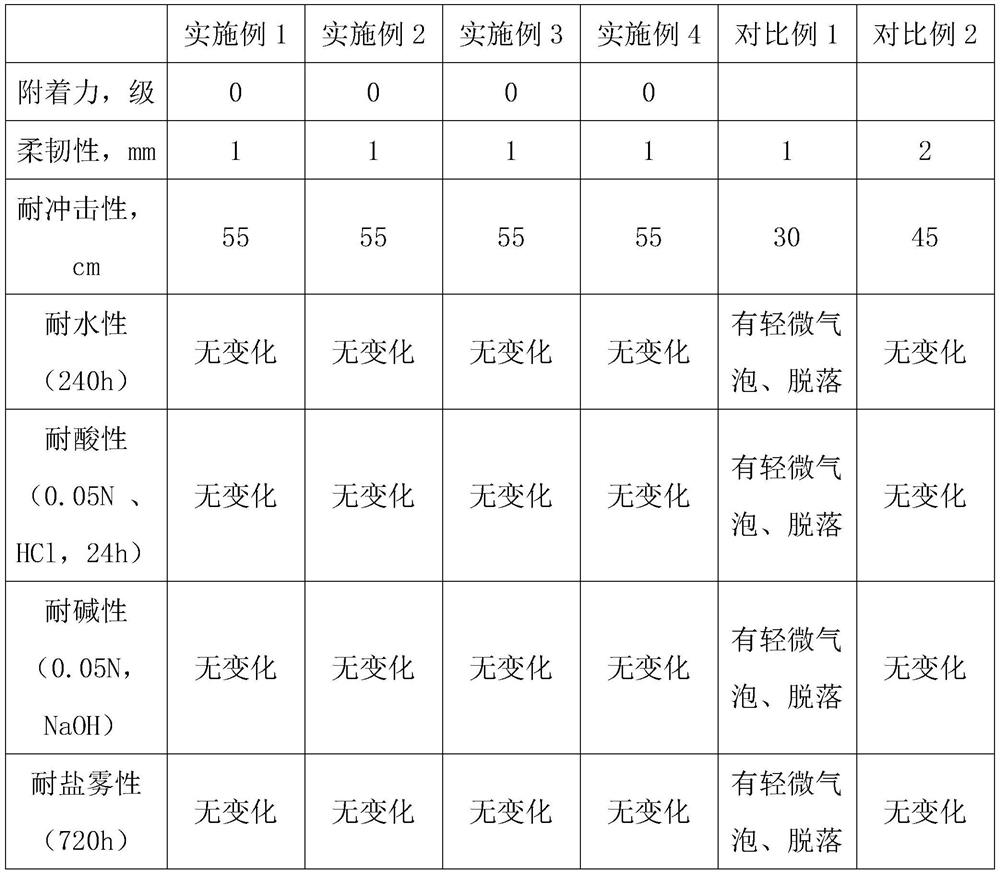

Examples

Embodiment 1

[0027] (1) In parts by weight, add 50.5g of bifunctional glycidyl ether epoxy resin into the first mixer, add 0.5g of organic silicon polymer while stirring, heat and control the material temperature to 55°C, add 10g of bisphenol A , Stir for the first time at 50 rpm for 30 minutes, adjust the rotation speed to 10 rpm after dissolving bisphenol A, then add 5g xylene, 5g n-butanol, 1g isopropanol, 2g bisphenol A liquid epoxy Resin, 8g cardanol-modified active diluent, then adjust the rotation speed, stir for the second time at 50 rpm for 10 minutes, and let it stand for 30 hours to obtain the mixed material A;

[0028] (2) Under nitrogen protection, add 7.5g of N,N-diethyl-1,3-propylenediamine and 8g of low-molecular-weight epoxy resin to the second mixer, heat the material to a temperature above 25°C and stop stirring. Place and process for 30h to obtain the mixed material B;

[0029] (3) Add the mixed material B to the mixed material A in the first mixer, then add 1g of hydr...

Embodiment 2

[0033] (1) In parts by weight, add 50.5g of bifunctional glycidyl ether epoxy resin to the first mixer, add 0.5g of organic silicon polymer while stirring, heat and control the temperature of the material to 65°C, add 10g of bisphenol A , Stir for the first time at 60 rpm for 45 minutes, adjust the rotation speed to 20 rpm after bisphenol A dissolves, then add 5g xylene, 5g n-butanol, 1g isopropanol, 2g bisphenol A liquid epoxy Resin, 8g cardanol-modified active diluent, then adjust the rotation speed, stir for the second time at 60 rpm for 15 minutes, and let it stand for 26 hours to obtain the mixed material A;

[0034] (2) Under nitrogen protection, add 7.5g of N,N-diethyl-1,3-propylenediamine and 8g of low-molecular-weight epoxy resin to the second mixer, heat the material to a temperature above 25°C and stop stirring. Place and process for 27h to obtain the mixed material B;

[0035] (3) Add the mixed material B to the mixed material A in the first mixer, then add 1g of ...

Embodiment 3

[0039] (1) In parts by weight, add 50.5g of bifunctional glycidyl ether epoxy resin into the first mixer, add 0.5g of organic silicon polymer while stirring, heat and control the material temperature to 60°C, add 10g of bisphenol A , Stir for the first time at 55 rpm for 35 minutes, adjust the rotation speed to 15 rpm after dissolving bisphenol A, then add 5g xylene, 5g n-butanol, 1g isopropanol, 2g bisphenol A liquid epoxy Resin, 8g cardanol-modified active diluent, then adjust the rotation speed, stir for the second time at 55 rpm for 10 minutes, and let it stand for 33 hours to obtain the mixed material A;

[0040] (2) Under nitrogen protection, add 7.5g of N,N-diethyl-1,3-propylenediamine and 8g of low-molecular-weight epoxy resin to the second mixer, heat the material to a temperature above 25°C and stop stirring. Place and process for 30h to obtain the mixed material B;

[0041] (3) Add the mixed material B to the mixed material A in the first mixer, then add 1g of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com