Polyaspartic acid shielding varnish, and preparation method and application thereof

A technology of polyaspartum and varnish is applied to polyaspartum shielding varnish based on polyaspartum resin and its preparation, and the field of polyaspartum shielding varnish can achieve the effects of prolonging service life, excellent aging resistance and excellent aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

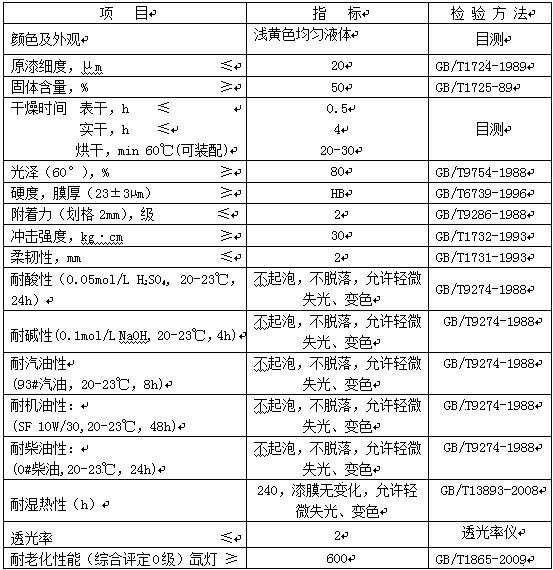

Image

Examples

Embodiment 1

[0070] A kind of polyaspartic shielding varnish, this varnish is made up of the raw material of following parts by weight:

[0071] Raw material ratio of the main agent:

[0072] Polyaspartic resin NH1420 75

[0073] Drier dibutyltin dilaurate 3

[0074] Defoamer SPX-35 0.5

[0075] UV absorber eversorb40 0.5

[0076] Leveling agent 360s 0.3

[0077] Thinner 20

[0078] Xylene 65

[0079] Butyl propionate 25

[0080] PMA (Propylene Glycol Methyl Ether Acetate) 5

[0081] Raw material ratio of hardener:

[0082] Polyisocyanate 75

[0083] Butyl propionate 25

[0084] Water absorption stabilizer OF 0.4

[0085] Preparation:

[0086] Preparation of polyaspartic shielding varnish:

[0087] Main agent: mix polyaspartic resin and some diluents evenly, add defoamer, ultraviolet absorber, leveling agent, drier in turn under stirring state, stir evenly, add diluent according to solid content to adjust solid content , filter package.

[0088] Hardener: mix polyisocyanate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com