Metal polishing solution and metal polishing method

A technology of polishing liquid and metal, which is applied in the field of metal polishing liquid and metal polishing, can solve the problems of large environmental pollution and environmental pollution, and achieve the effect of reducing pollution, reducing corrosion efficiency and improving the quality of metal surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

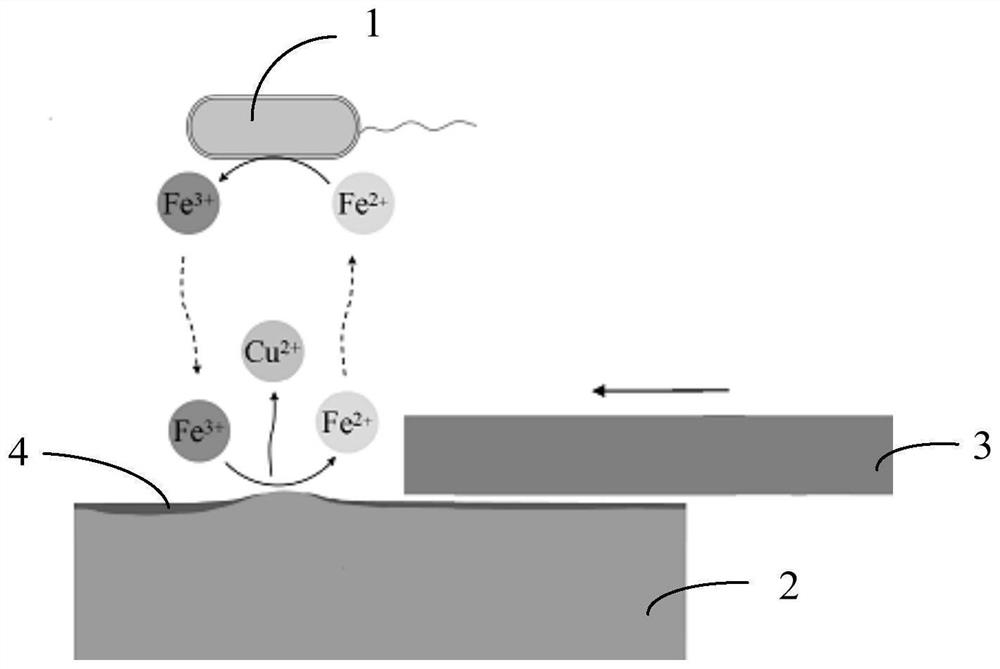

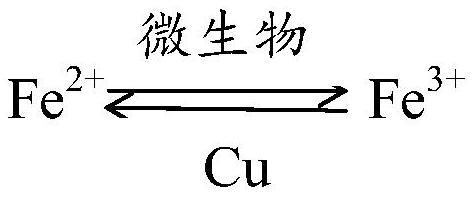

Method used

Image

Examples

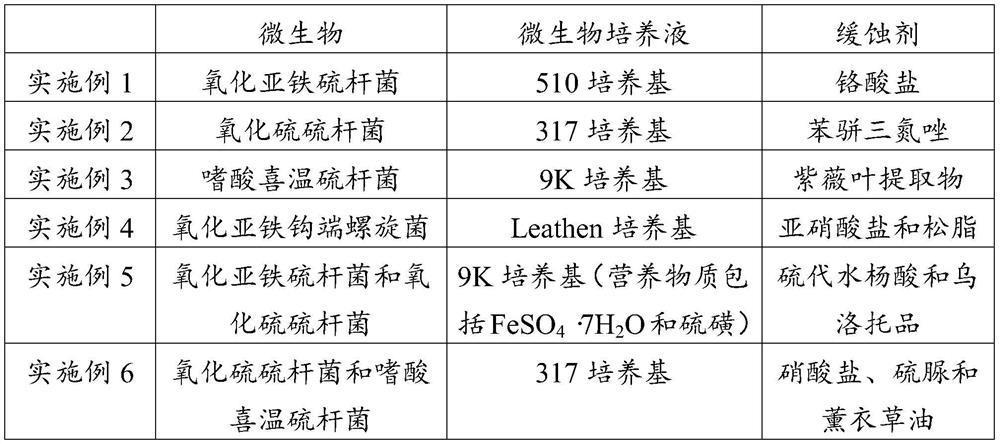

Embodiment 1

[0054] (1) Microorganism 1 (Thiobacillus ferrooxidans) in 8.5×10 5 The concentration of each / mL was inoculated in 510 medium (the pH value of the medium was 2), and after culturing at 25°C for 20 hours, the color of the culture solution turned yellowish brown (due to the light green Fe in the medium). 2+ ions are continuously converted by Thiobacillus ferrooxidans into yellow Fe 3+ ion), after detection, the concentration of Thiobacillus ferrooxidans was 7.5×10 6 individual / mL, and Fe 3+ When the ion concentration reaches 5g / L, the cultivation is stopped; chromate is added to the above-mentioned microorganism 1 and the microorganism culture solution at a concentration of 10mg / L, and mixed evenly to obtain a metal polishing solution, which is set aside.

[0055] (2) Copper 2 is degreased, deburred, and metal shavings are removed, and then copper 2 is soaked in the above-mentioned metal polishing solution for polishing treatment, and the temperature of the polishing treatment ...

Embodiment 2

[0058] (1) Thiobacillus thiooxidans was treated with 1.2×10 4 The concentration of each / mL was inoculated in 317 medium (the pH value of the medium was 1), and after culturing at 20°C for 48h, the concentration of Thiobacillus thiooxidans was 8.5×10 6 individual / mL, and the metabolite SO 4 2- When the ion concentration reaches 10g / L, and the pH value reaches below 1, stop the cultivation; add benzotriazole at a concentration of 5 mg / L to the above-mentioned microorganisms and the microorganism culture solution, mix well to obtain a metal polishing solution, and set aside.

[0059] (2) Degrease, remove burrs, and remove metal shavings from the iron, then soak the iron in the above metal polishing solution for polishing, and the temperature of the polishing treatment is 20°C, and use a flexible polishing pad made of fiber to perform auxiliary polishing deal with.

[0060] (3) After about 12 minutes, the iron is taken out from the metal polishing solution, and the soaked iron is...

Embodiment 3

[0062] (1) Thiobacillus acidophilus was treated with 2.3×10 6 The concentration of each / mL was inoculated in 9K medium (the pH value of the medium was 3), and after culturing at 40°C for 28 hours, the concentration of Thiobacillus acidophilus was 9.3×10 8 individual / mL, and the metabolite SO 4 2- When the ion concentration reaches 15g / L, and the pH value reaches below 1, stop the cultivation; add the crape myrtle leaf extract at a concentration of 20mg / L to the above-mentioned microorganisms and microorganism culture solution, mix well, and obtain a metal polishing solution for future use.

[0063] (2) Degrease, remove burrs, and remove metal shavings from the lead, then soak the lead in the above metal polishing solution for polishing, and the temperature of the polishing treatment is 40°C, and use a flexible polishing pad made of leather for auxiliary polishing deal with.

[0064] (3) After about 10 minutes, the lead is taken out from the metal polishing solution, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com