Velvet cutting machine system and using method thereof

A cashmere cutting machine and cashmere machine technology, applied in the field of cashmere cutting machine systems, can solve the problems of uncontrollable gravity free fall and swing up and down, uneven cut surface, uneven length of finished fibers, etc., to achieve smooth surface and improve production. Quality, the effect of solving overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

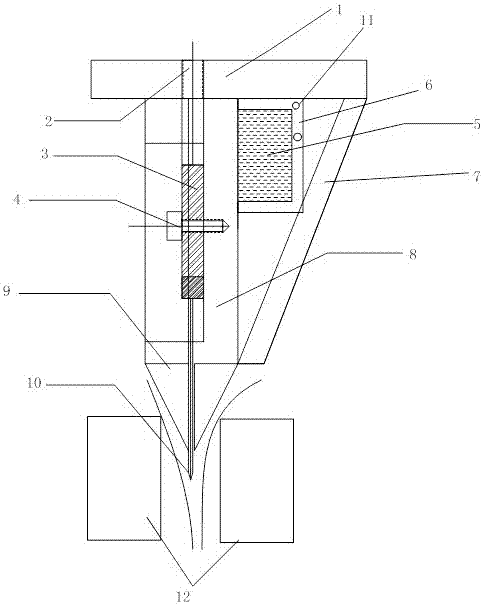

[0023] Such as figure 1 As shown, the velvet cutting machine system of the present invention includes:

[0024] The clamping part of the pile cutting machine is used to move the cut pile blank vertically upwards, fix the pile blank between the two clamping beams 12, and prevent the pile blank from swinging on both sides; between the knife edge and the two clamping beams Corresponding; this part also includes the fixed plate 1, the limit block adjustment bolt 2, the blade stabilization limit block 3, the blade limit block fixing bolt 4, the blade and the blade cooling channel 5, the water tank 6, the inclined stop Plate 7, inner clamping plate 8, outer clamping plate 9, knife strip 10, outer circulation interface 11, limit block adjusting bolt 2 is located in the middle of the fixed plate 1 and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com