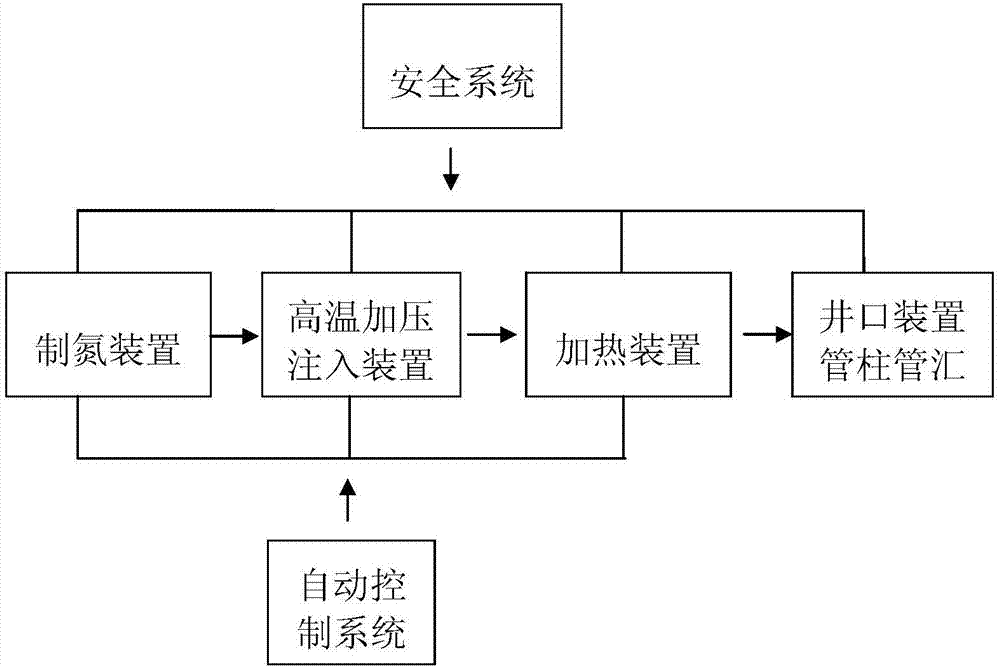

Oil-gas well hot N2 plugging removal technology method and device

A process method and technology for oil and gas wells, applied in isolation devices, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as unsatisfactory effects, and achieve the effects of wide sources, high plugging removal efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

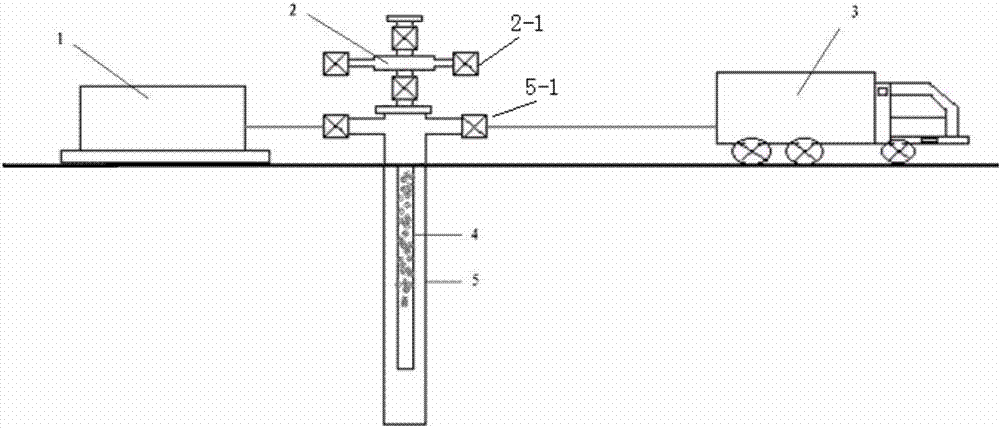

[0028] Example 1: Simple production string plugging

[0029] 1. Connect the nitrogen generating device, high-pressure injection device, and heating device to the oil (gas) production wellhead through the surface pipeline.

[0030] 2. Pressure test the injection pipeline according to the level of oil (gas) production wellhead. Ordinary oil production wellhead pressure test is 21Mpa, and wellhead pressure test of 35MPa or more is 25MPa, and it is qualified without puncture or leakage.

[0031] 3. Inject hot nitrogen from the annular space of the oil jacket, stay for a certain period of time, release the pressure, inject hot nitrogen again, release the pressure again, repeat this several times, and dissolve the wax in the column through the exchange of hot nitrogen.

Embodiment 2

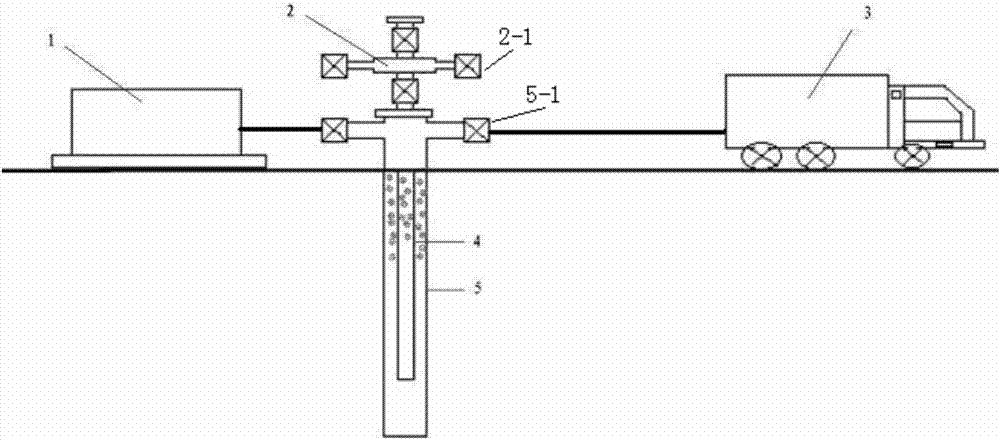

[0032] Example 2: The tubing annulus and the production string are blocked and there is no circulation channel

[0033] 1. Connect the nitrogen generating device, high-pressure injection device, and heating device to the oil (gas) production wellhead through the surface pipeline.

[0034] 2. Pressure test the injection pipeline according to the level of oil (gas) production wellhead. Ordinary oil production wellhead pressure test is 21Mpa, and wellhead pressure test of 35MPa or more is 25MPa, and it is qualified without puncture or leakage.

[0035] 3. Alternately inject hot nitrogen from the inside of the production pipe string or the annular space of the oil jacket, and after staying for a certain period of time, release the pressure and vent, then inject hot nitrogen again, and release the pressure again, repeat this several times, through the exchange of hot nitrogen, dissolve the inside Wax, so that the solid section of the blockage in the column gradually moves down, an...

Embodiment 3

[0036] Example 3: The oil casing of the pipe string with a packer on the bottom is blocked

[0037] 1. Connect the nitrogen generating device, high-pressure injection device, and heating device to the oil (gas) production wellhead through the surface pipeline.

[0038] 2. Pressure test the injection pipeline according to the level of oil (gas) production wellhead. Ordinary oil production wellhead pressure test is 21Mpa, and wellhead pressure test of 35MPa or more is 25MPa, and it is qualified without puncture or leakage.

[0039] 3. Install the coiled tubing, inject hot nitrogen from the coiled tubing, lift and release the coiled tubing and circulate the hot nitrogen to dissolve the blockage in the string.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com