Tight reservoir sweetness evaluation method and device

A tight reservoir and sweetness evaluation technology, applied in the field of exploration and development of tight reservoir gas reservoirs, can solve the problems of low accuracy, failure to consider the development degree of natural fractures and fracturing fluid fluid seepage into fractures, and large errors in characterization results , to improve the evaluation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

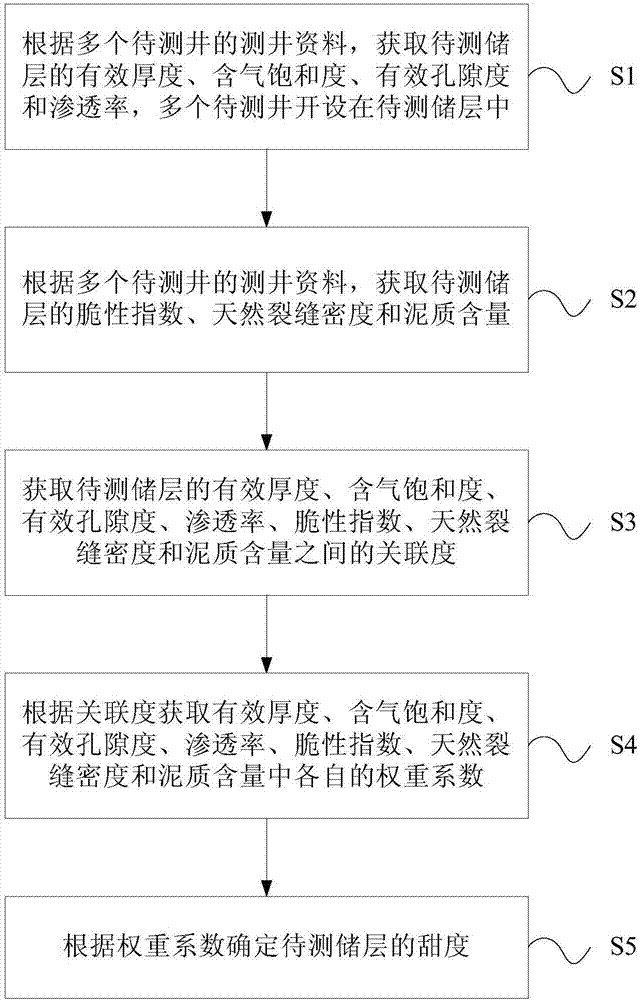

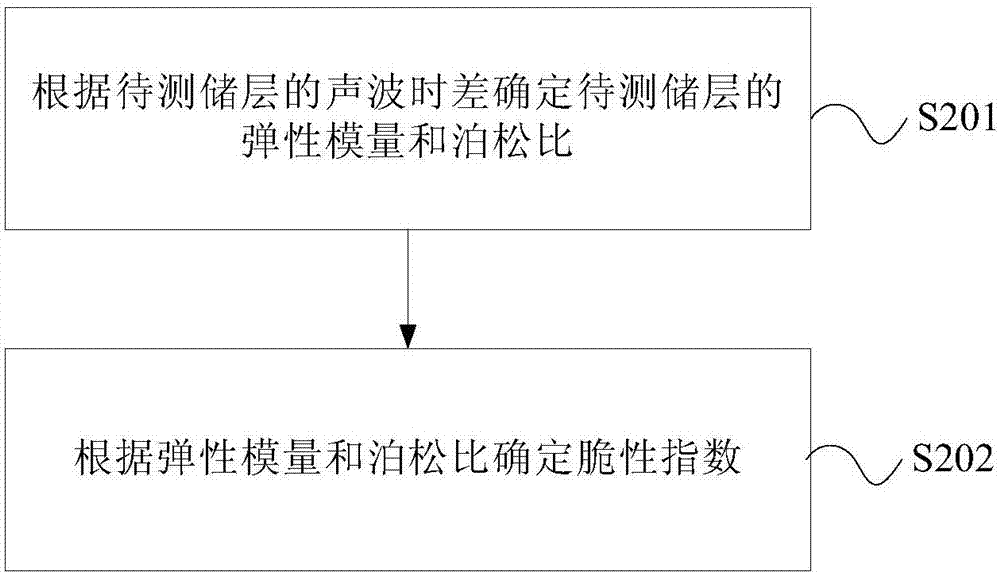

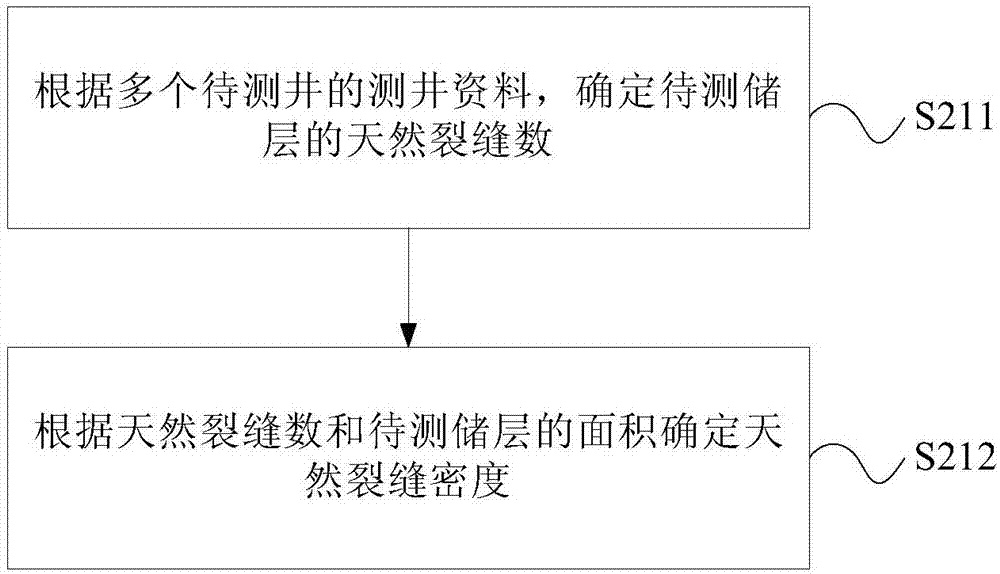

[0028] figure 1 It is a schematic flow chart of the method for evaluating the sweetness of tight reservoirs provided in the first embodiment of the present invention. figure 2 It is a schematic diagram of the process of obtaining the brittleness index of the reservoir to be tested in the method for evaluating the sweetness of tight reservoirs provided in the first embodiment of the present invention. image 3 It is a schematic diagram of the process of obtaining the natural fracture density of the reservoir to be tested in the method for evaluating the sweetness of tight reservoirs provided in the first embodiment of the present invention. Figure 4 It is a schematic flow chart of determining the sweetness of the reservoir to be tested in the method for evaluating the sweetness of tight reservoirs provided in the first embodiment of the present invention.

[0029] Such as Figure 1-Figure 4 As shown, Embodiment 1 of the present invention provides a method for evaluating the sweetn...

Embodiment 2

[0124] In addition, Figure 5 It is a schematic diagram of the structure of a device for evaluating sweetness of tight reservoirs provided in the second embodiment of the present invention. Such as Figure 5 As shown, the tight reservoir sweetness evaluation device 50 provided in the second embodiment of the present invention includes:

[0125] The first analysis module 51 obtains the effective thickness, gas saturation, effective porosity, and permeability of the reservoir to be tested based on the logging data of multiple wells to be logged, and multiple wells to be logged are opened in the reservoir to be tested .

[0126] It should be noted that multiple wells to be logged are opened in the reservoir to be tested, and logging data is obtained through logging. The effective thickness, gas saturation, effective porosity, and permeability of the reservoir to be tested can be measured through logging. The information is obtained directly. By selecting the effective thickness, gas...

Embodiment 3

[0137] In addition, Image 6 It is a schematic diagram of the structure of a device for evaluating sweetness of tight reservoirs provided in the third embodiment of the present invention. Such as Image 6 As shown, the tight reservoir sweetness evaluation device 60 provided in the third embodiment of the present invention includes:

[0138] The memory 61 is used to store instructions; specifically, the storage objects of the memory 61 include software and modules. The processor 62 is configured to run the instructions stored in the memory 61 to execute the method for evaluating the sweetness of the dense reservoir provided in the first embodiment. The processor 62 executes various functions and processing data of the compact reservoir sweetness evaluation device 60 by running or executing software programs and / or modules stored in the memory 61 and calling data stored in the memory 61.

[0139] Specifically, the processor 62 is used to obtain the effective thickness, gas saturatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com