Experimental facility for simulating flow condition variations of multiple diameter expanding sections in natural gas hydrate well drilling

A technology of flow state and experimental device, applied in drilling equipment, earthmoving, wellbore/well components, etc., can solve the problems of high torque, high friction, and poor cleaning effect of horizontal section wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

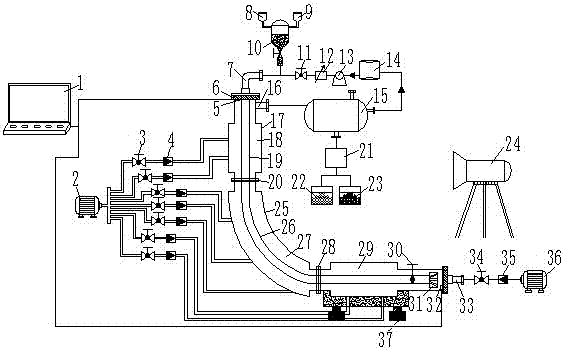

[0023] Such as figure 1 As shown, an experimental device for simulating the flow state change of various expansion sections of natural gas hydrate drilling, which includes a mixture inlet 7 connected sequentially from top to bottom, a casing joint A6, a vertical section outer pipe 17, and a flange joint A20 , the outer pipe 25 of the inclined well section, the flange joint B28, the outer pipe of the horizontal section and the casing joint B, the outer pipe 17 of the vertical section is provided with the inner pipe 19 of the vertical section, and the outer pipe 25 of the inclined well section is provided with the inclined well Section inner pipe 26, the horizontal section outer pipe is provided with a horizontal section inner pipe, one end of the horizontal section inner pipe is connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com