Six-gear automatic transmission

An automatic transmission, six-speed technology, applied in the field of automobile transmission system, can solve the problems affecting the stability and service life of the transmission, complicated control oil circuit, and many layout spaces, etc., and achieves shortened axial length, simple connection, and reduced The effect of idling losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

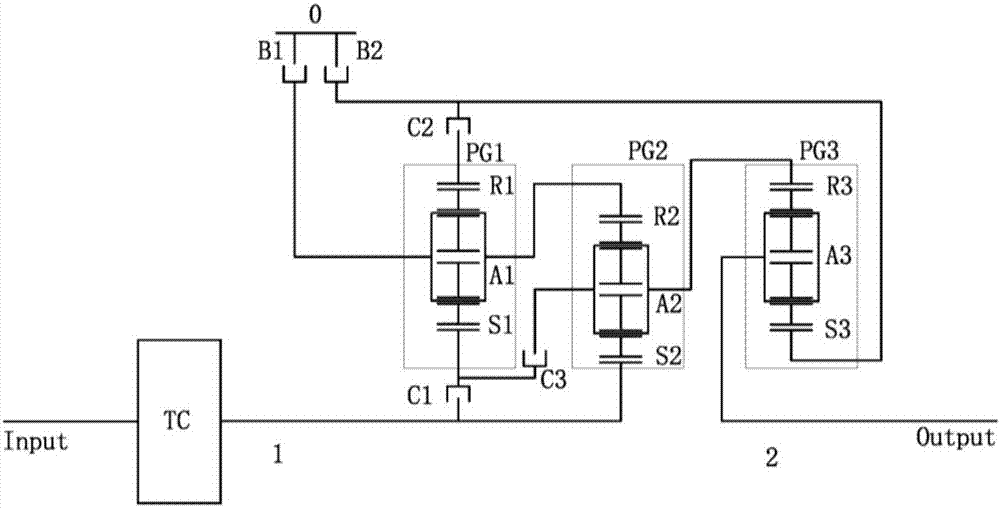

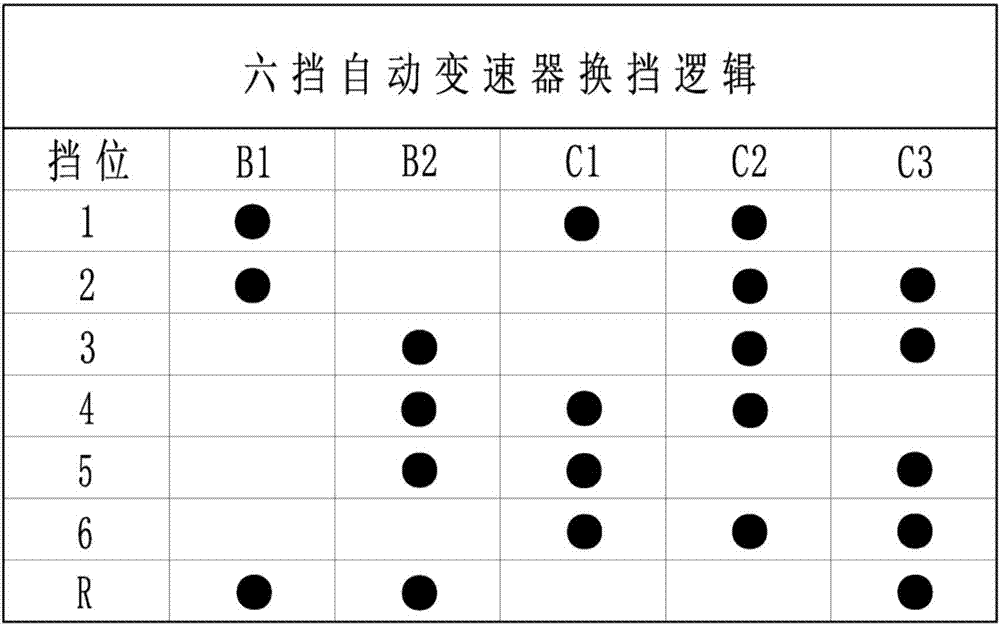

[0030] Such as figure 1 Shown: the present invention provides a six-speed automatic transmission, which consists of 3 planetary gear sets (the first planetary gear set PG1, the second planetary gear set PG2, the third planetary gear set PG3) and 5 shift elements (the first Brake B1, second brake B1, first clutch C1, second clutch C2, third clutch C3), six-speed automatic transmission case 0, first shaft 1 of six-speed automatic transmission, second shaft of six-speed automatic transmission 2 components, and in order to illustrate the route of power transmission through the six-speed automatic transmission, figure 1 The components shown include the input shaft Input, the torque converter TC, and the output terminals on both sides of the differential; the relationship between them is: 3 planetary gear sets, 5 shifting elements, and a six-speed automatic transmission The first shaft 1 of the six-speed automatic transmission and the second shaft 2 of the six-speed automatic trans...

no. 2 example

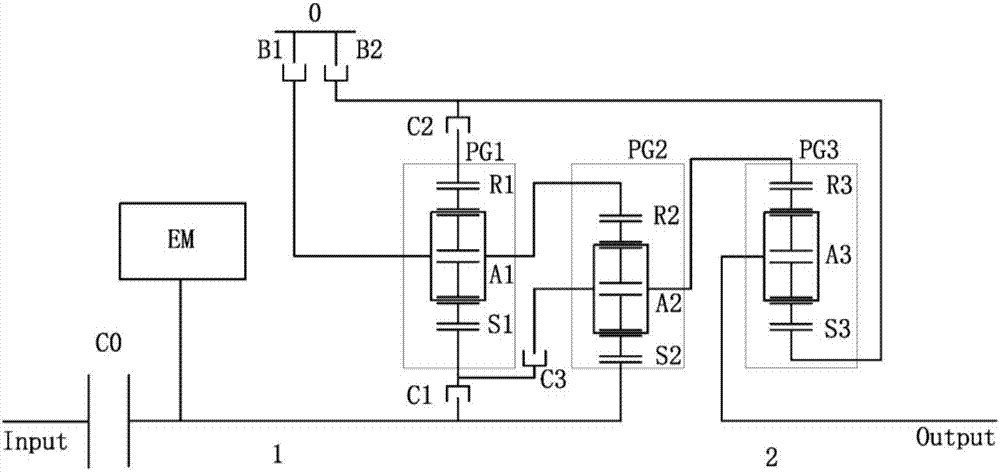

[0036] Such as figure 2 Shown: the second embodiment is another application of the six-speed automatic transmission described in the first embodiment, which is called a hybrid power transmission scheme. The structure of the second embodiment is basically the same as that of the first embodiment, except that the torque converter TC is replaced by the electric motor TM, and the zeroth clutch C0 is added. The zeroth clutch C0 is arranged between the input shaft Input and the first shaft 1 of the six-speed automatic transmission and is connected with them, and the motor TM is connected with the first shaft 1 of the six-speed automatic transmission;

[0037] The zeroth clutch C0 is used to cut off and connect the power provided by the engine of the vehicle. When the vehicle starts or runs at low speed, the clutch C0 is opened, and only the motor TM drives the transmission system; when the vehicle requires high power, such as high-speed driving conditions, the clutch C0 is closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com