Ammonia gas sensor for room temperature and preparation method thereof

An ammonia sensor and room temperature technology, applied in the field of sensors, can solve problems such as poor selectivity, poor stability, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Step 2. Preparation of nanotubes: connect the needle of the disposable syringe to the positive pole of the high-voltage DC power supply, and fix it at a height of 15-20cm from the collection plate, set the spinning voltage to 15-20KV, and fix the clean aluminum foil to the desktop. On the negative pole of the high-voltage power supply. Turn on the high-voltage power supply, the needle of the disposable needle tube appears Taylor cone and starts spinning, deposit a sinking nanofiber on the aluminum foil of the receiver, after spinning, put it in the muffle furnace for annealing treatment, the heating rate is 4-6 ℃ / min, heat up to 680-720℃, hold time for 3.5-5 hours, then cool freely to room temperature, and finally get one-dimensional SrGe 4 O 9 nanotube;

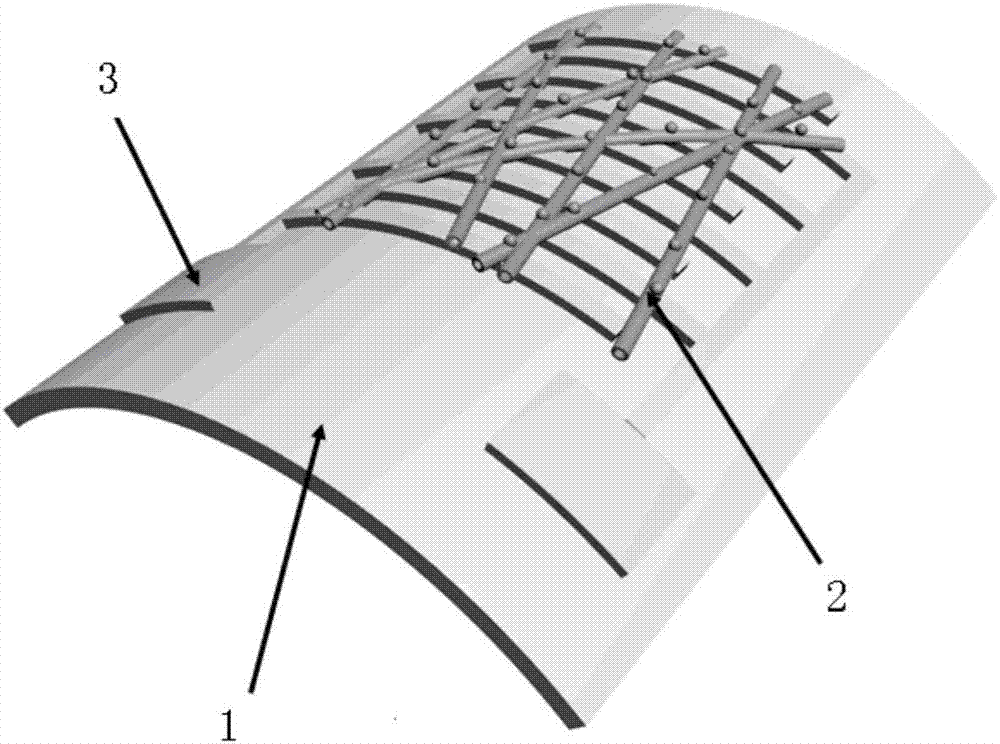

[0043] Step 3. Production of the sensor:

[0044] Step 3.1: Use acetone, ethanol and distilled water to clean the substrate in sequence, and set aside;

[0045] Step 3.2: Weigh an appropriate amount of one-dimensional SrGe...

Example Embodiment

[0048] Example 1:

[0049] One-dimensional SrGe 4 O 9 Take nanotubes as an example to introduce the preparation process in detail:

[0050] (1) Precursor solution configuration: at room temperature, 0.1046g strontium nitrate Sr(NO 3 ) 2 Powder and 0.5g ethoxy germanium ([Ge(OEt) 4 ]) mixed, put into 3.5g absolute ethanol, 17.5g N,N-dimethylformamide (DMF) and 0.5g deionized water mixed solution to dissolve, then add 2.99g polyvinylpyrrolidone (PVP, 130 10,000 molecular weight) powder. Finally, the mixed solution is magnetically stirred for 4 hours until the mixed solution is clear, transparent and uniform. Then, use a dropper to suck about 1ml of the solution into the disposable syringe, ready to start electrospinning.

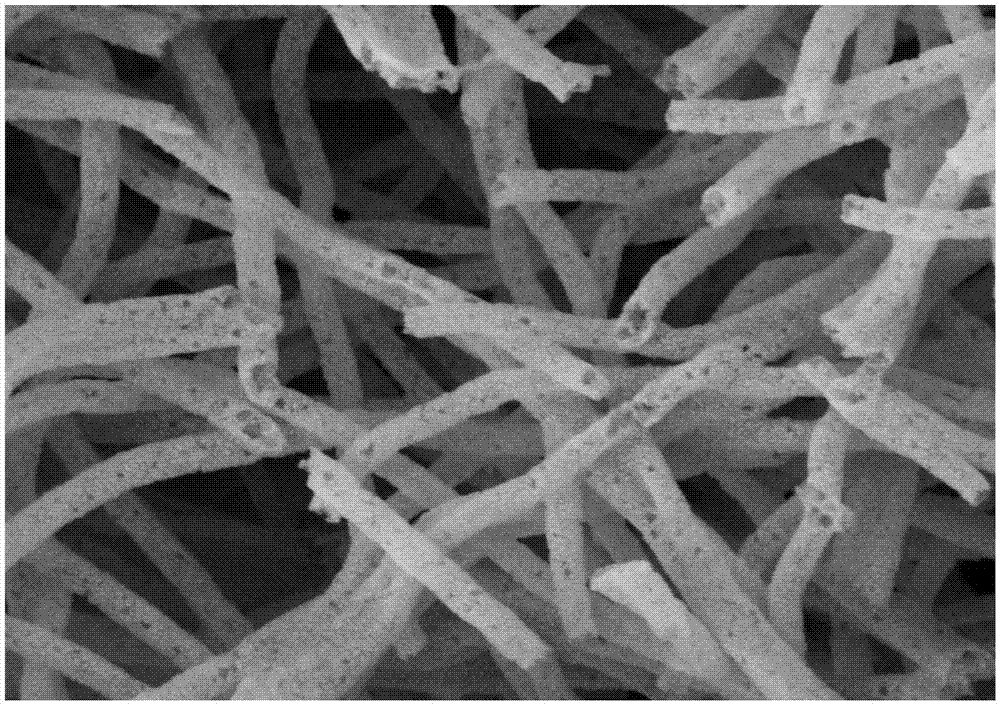

[0051] (2) Preparation of nanotubes: Connect the needle of the disposable syringe to the positive pole of the high-voltage DC power supply and fix it at a height of 15 cm from the collection plate. The spinning voltage is set to about 15KV. Connect the clean alum...

Example Embodiment

[0054] Example 2:

[0055] One-dimensional SrGe 4 O 9 Take nanotubes as an example to introduce the preparation process in detail:

[0056] (1) Precursor solution configuration: at room temperature, 0.1046g strontium acetate Sr(NO 3 ) 2 Powder and 0.5g ethoxy germanium ([Ge(OEt) 4 ]) mixed, put into 3.5g absolute ethanol, 17.5g N,N-dimethylformamide (DMF) and 0.5g deionized water mixed solution to dissolve, then add 2.99g polyvinylpyrrolidone (PVP, 130 10,000 molecular weight) powder. Finally, the mixed solution is magnetically stirred for 4 hours until the mixed solution is clear, transparent and uniform. Then, use a dropper to suck about 1ml of the solution into the disposable syringe, ready to start electrospinning.

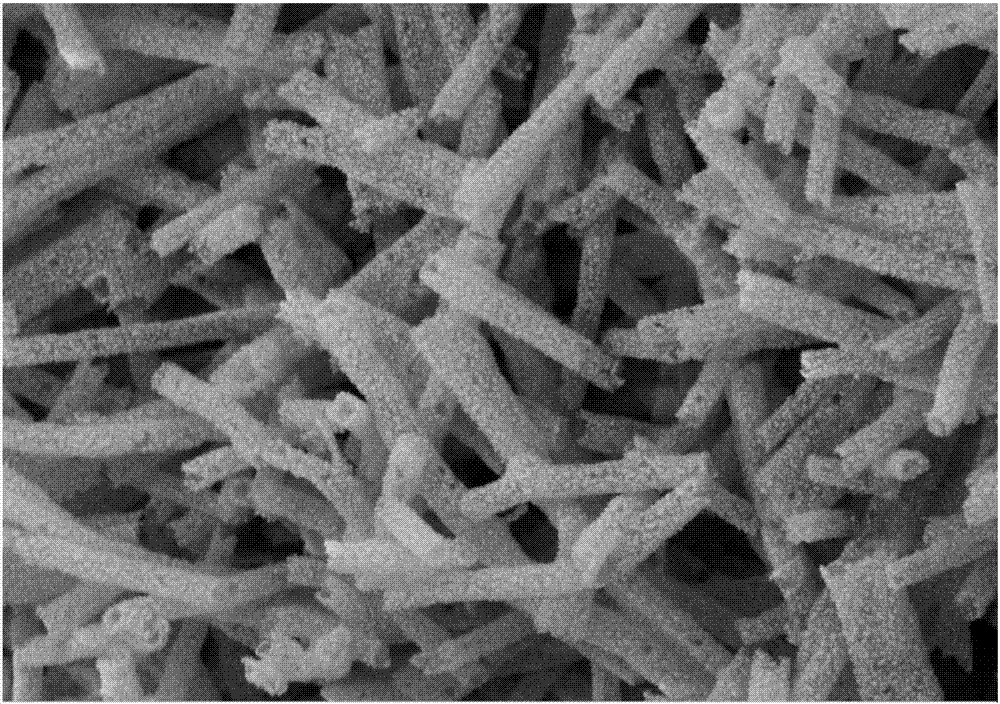

[0057] (2) Preparation of nanotubes: Connect the needle of the disposable syringe to the positive pole of the high-voltage DC power supply and fix it at a height of 20 cm from the collection plate. The spinning voltage is set to about 15KV. Connect the clean alum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap