Grid scanning drive circuit and liquid crystal display device

A driving circuit, gate scanning technology, applied in static indicators, nonlinear optics, instruments, etc., can solve problems such as the negative impact of thin film transistors, and achieve the effect of improving repairability and adding auxiliary repair modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

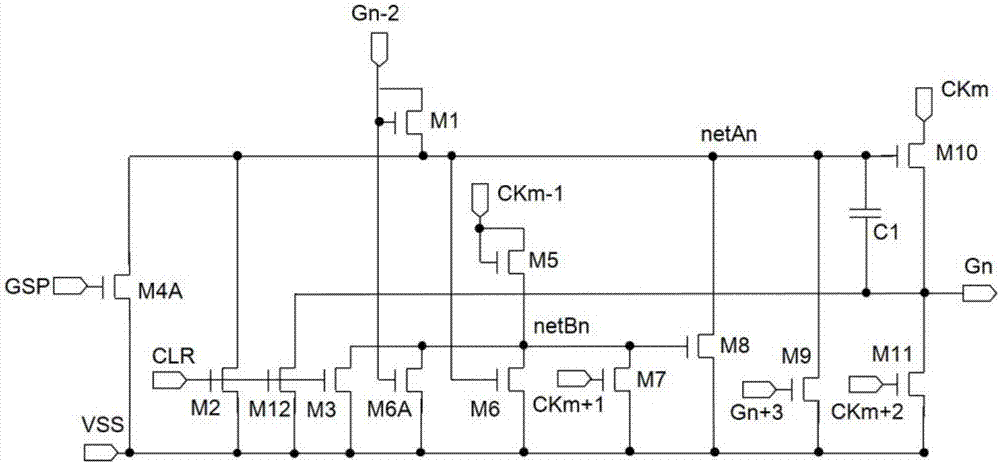

[0063] figure 2 It is a schematic circuit diagram of Embodiment 1 of a gate scanning drive circuit of the present invention, as shown in figure 2 As shown, a gate scanning driving circuit includes a multi-level gate driving unit, each gate driving unit includes: a pull-up control module 01, a pull-up module 03, a pull-down clearing module 04, and a main maintenance module 05; The main maintenance module 05 includes a maintenance control node generation module and a node maintenance module connected thereto; both the pull-up control module 01 and the maintenance control node generation module are connected to the first front-end signal; the pull-up module 03 is connected to the current-level scanning signal line Gn ; Pull-down clearing module 04 is connected to the rear level signal; pull-up control module 01, pull-up module 03 and pull-down clearing module 04 are all connected to the pull-up control node netAn; maintain the control node to generate module input low level VSS...

Embodiment 2

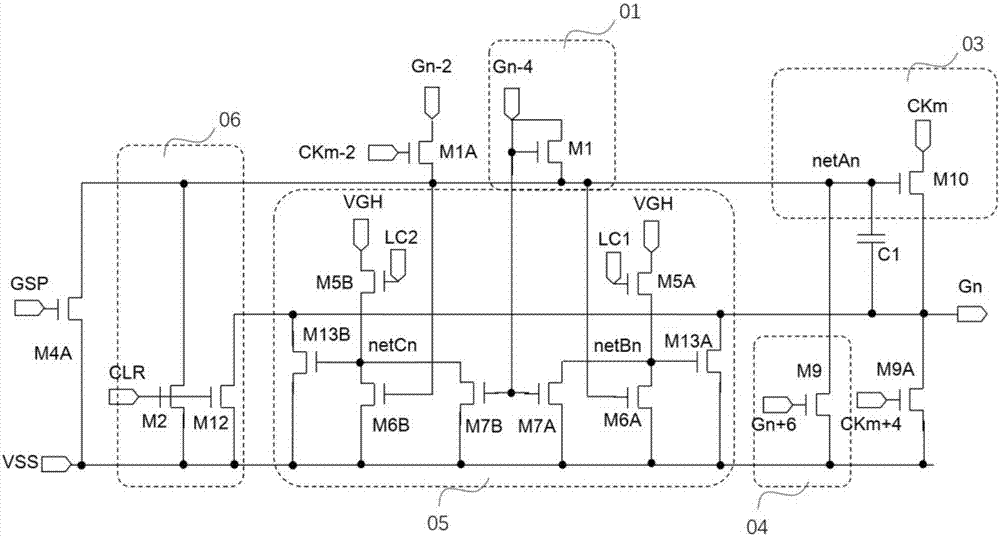

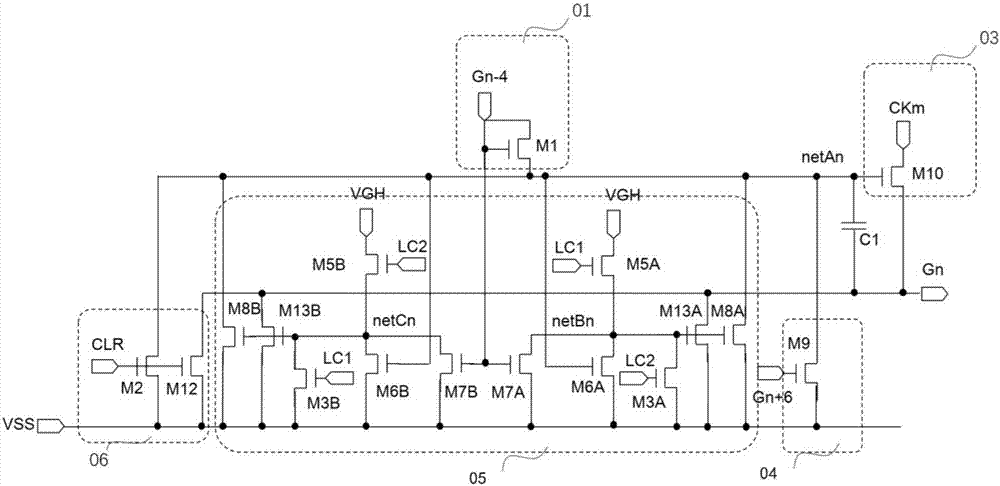

[0088] image 3 It is a schematic circuit diagram of Embodiment 2 of a gate scanning driving circuit of the present invention, as shown in image 3 As shown, the circuit composition structure of the second embodiment is basically the same as that of the first embodiment above, and does not include the stage transmission module 02 and the stage transmission signal maintenance module 053. The node maintenance control module further includes a pull-up control node maintenance module for maintaining the pull-up control node netAn, the pull-up control node maintenance module includes an eighth thin film transistor M8A and an eighteenth thin film transistor M8B, and the eighth thin film transistor The gate of M8A is connected to the first maintenance control point netBn, the source of the eighth thin film transistor M8A is connected to the pull-up control node netAn, the drain of the eighth thin film transistor M8A is connected to the low level VSS, the eighteenth thin film transist...

Embodiment 3

[0093] Figure 4 It is a schematic circuit diagram of Embodiment 3 of a gate scanning driving circuit of the present invention, as shown in Figure 4 As shown, the circuit composition structure of the third embodiment is basically the same as that of the second embodiment above, and does not include the stage transmission module 02 and the stage transmission signal maintenance module 053. The nineteenth thin film transistor M1A and the twentieth thin film transistor M4A can be set as functional modules that assist in maintaining the pull-up control node netAn.

[0094] The gate of the nineteenth thin film transistor M1A is connected to the front stage clock signal CKm-2, the source of the nineteenth thin film transistor M1A is connected to the second front stage signal, and the drain of the nineteenth thin film transistor M1A is connected to the pull-up control node net An.

[0095] The gate of the twentieth TFT M4A is connected to the start signal GSP, the source of the twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com