Hydraulic door opening device

A hydraulic and water injection nozzle technology, applied in life-saving equipment, building rescue, etc., can solve the problems of unfavorable protection of indoor hostage personnel safety, large number of killing debris, reducing killing debris, etc., to achieve safe anti-terrorism rescue operations, wide range of blasting, and blasting low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

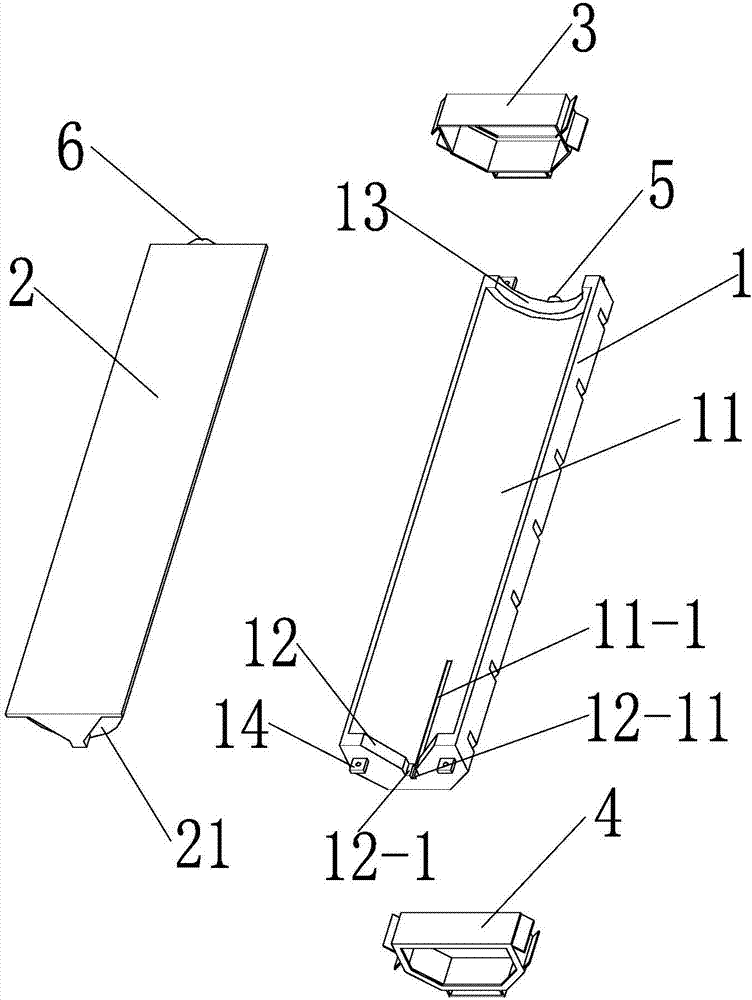

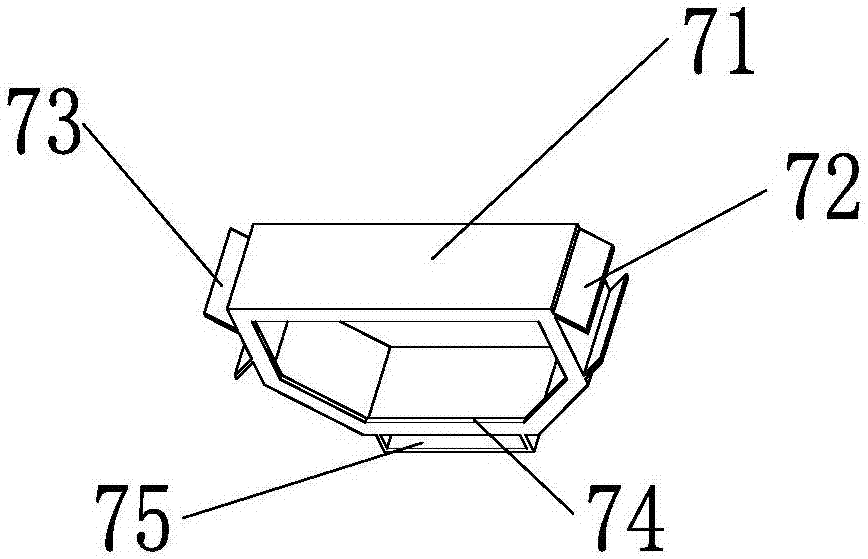

[0030] Such as Image 6 The shown hydraulic door breaking device connects two or more hydraulic door breaking devices side by side. The connection method is: connect the left connecting sleeve 3 on the right side of the inner eight-shaped plug 72 on one of the hydraulic door breaking devices to the corresponding The outer eight-shaped plug 73 on the left side of the left connecting sleeve 3 on the adjacent other hydraulic door breaking device is slidingly inserted into the combination; the outer eight-shaped plug 73 on the right side of the left connecting sleeve 3 on the right connecting sleeve 4 and The interlocking combination of the eight-shaped plug 72 on the left side of the left connecting collar 3 on another adjacent hydraulic door breaking device realizes the mutual locking between two or more hydraulic door breaking devices side by side.

Embodiment 2

[0032] Such as Figure 7 The shown hydraulic door breaking device connects two or more hydraulic door breaking devices in series. The connection method is: use a suitable piece of wood to pass through the left connecting collar 3 and the first hydraulic door breaking device in turn. The insert ring 75 of the right connecting ring 4 passes through the left connecting ring 3 and the insert ring 75 of the right connecting ring 4 on the first hydraulic door breaking device arranged axially, realizing two or more hydraulic power The series combination of door breaking device, the length of wood strip is about 5cm*0.8cm.

[0033] A hydraulic door breaking device of the present invention, the specific process of using this device:

[0034] 1. Remove the left connecting collar 3 and the right connecting collar 4 from both sides, and separate the energy-concentrating bottle 1 from the broken bottle 2. The volume of the energy-forming bottle 1 is 1.1L, and the volume of the broken bottle 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com