Aluminum-magnesium alloy dust treatment device for automobile production

A technology of dust treatment and magnesium-aluminum alloy, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of unreasonable discharge of hydrogen, easy dust clogging of filters, incomplete dust treatment, etc. Achieving the effect of avoiding explosion, broad application prospect and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

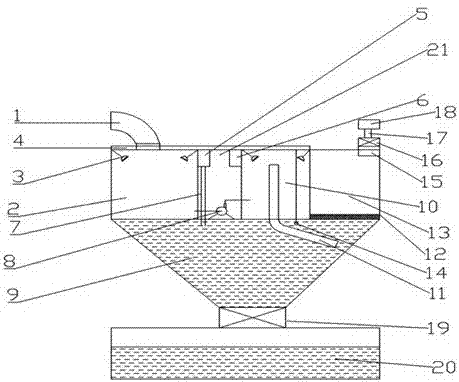

[0021] The lower part of the baffle shared by the first processing chamber and the second processing chamber, the second processing chamber and the third processing chamber described in this example is located at 20 cm below the liquid level, and the sides and top of the baffle are sealed with the filter housing, that is, the four sides are all sealed. Sealing, the air inlet of the trachea is 15cm away from the top of the filter housing, the air outlet of the trachea is 40cm below the water surface, and the adsorption plate is 20cm away from the water surface. When the air containing aluminum-magnesium dust enters into the treatment chamber 2 through the air inlet 1, the water pump B6 is opened, and the water in the water pump B6 enters the nozzle 3 through the water delivery pipe A4 for spraying, and the water contacts the aluminum-magnesium dust to make the aluminum-magnesium dust The dust becomes wet dust, and the wet dust enters into the water of the dust filter 9 by gravit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com