Two-DOF (two-degree-of-freedom) modular joint assembly based on hollow integrated motor

A technology of modular joints and degrees of freedom, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of increasing time and economic cost, reducing reliability and stability, extending the debugging period and maintenance period, etc. Improved reliability and stability, high reliability, optimized footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

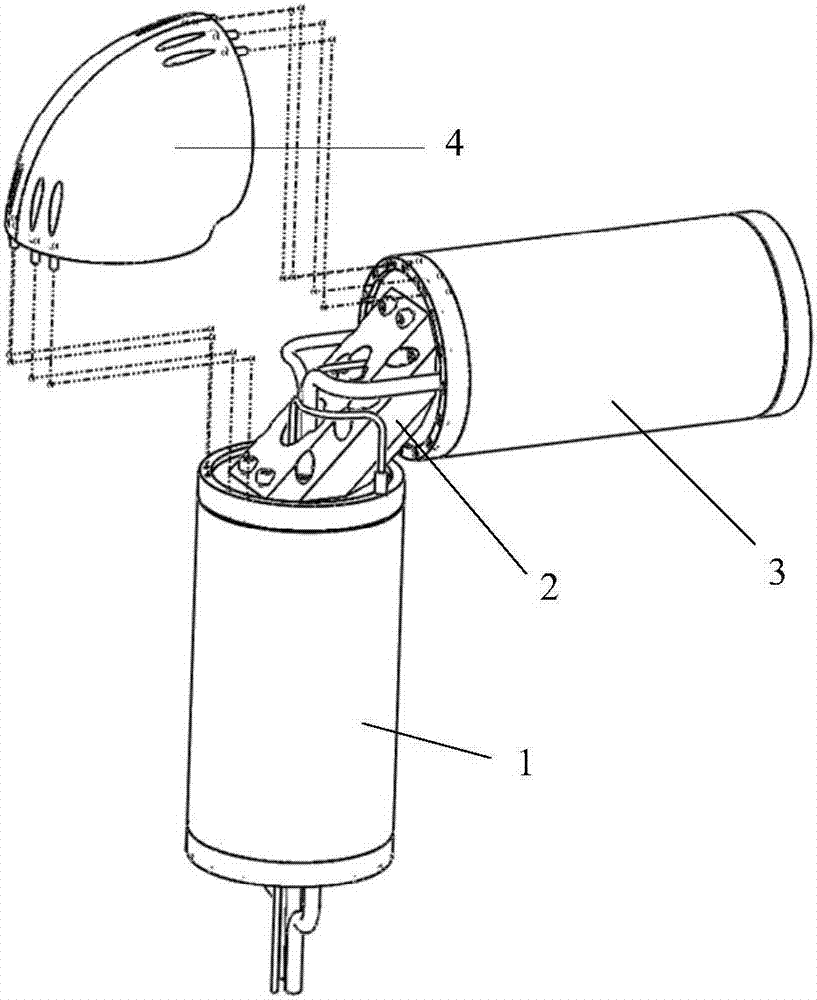

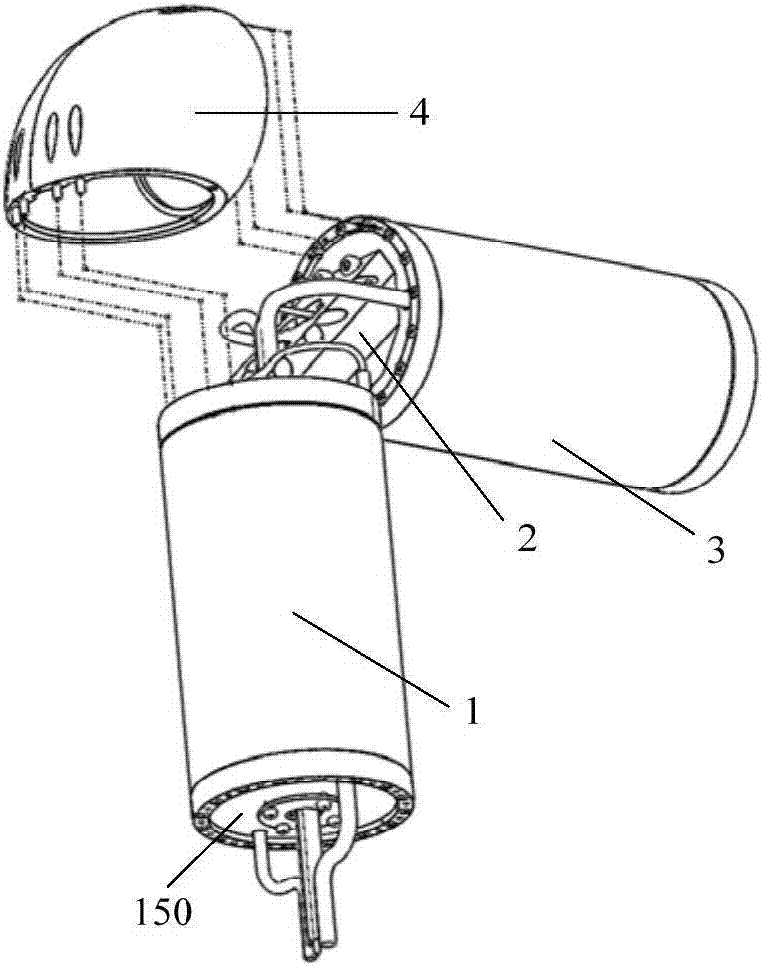

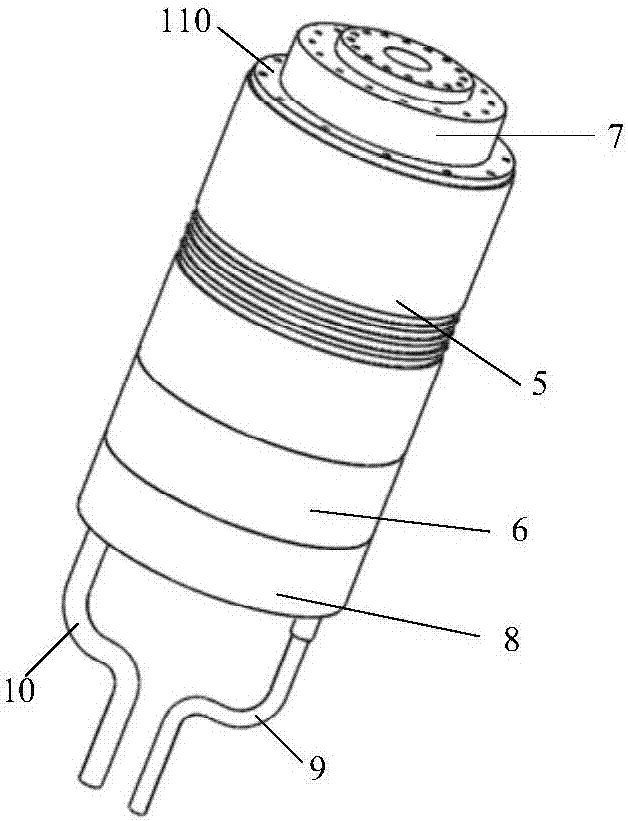

[0027] see Figure 1-7 , the embodiment of the present invention provides a two-degree-of-freedom modular joint assembly based on a hollow integrated motor, which includes: an X-axis motion unit 1 , an elbow 4 and a Y-axis motion unit 3 . The X-axis motion unit 1 is an X-axis motion unit that can rotate around its axis, that is, the X-axis motion unit 1 can rotate along its own axis. The Y-axis motion unit 3 is a Y-axis motion unit that can rotate around its axis, that is, the Y-axis motion unit 3 can rotate along its own axis. The axis of the X-axis motion unit 1 and the axis of the Y-axis motion unit 3 are perpendicular to each other. One end of the elbow 4 (or shell) is connected to the rotating output end of the X-axis motion unit 1, and the other end is connected to the fixed end of the Y-axis motion unit 3, so that the elbow 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com