Hanging system

A suspension system and connecting arm technology, applied in the field of mobile robots, can solve problems such as difficult to meet high performance requirements, achieve the effects of reducing labor intensity and part of the capital expenditure, improving competitiveness, and stable and efficient working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

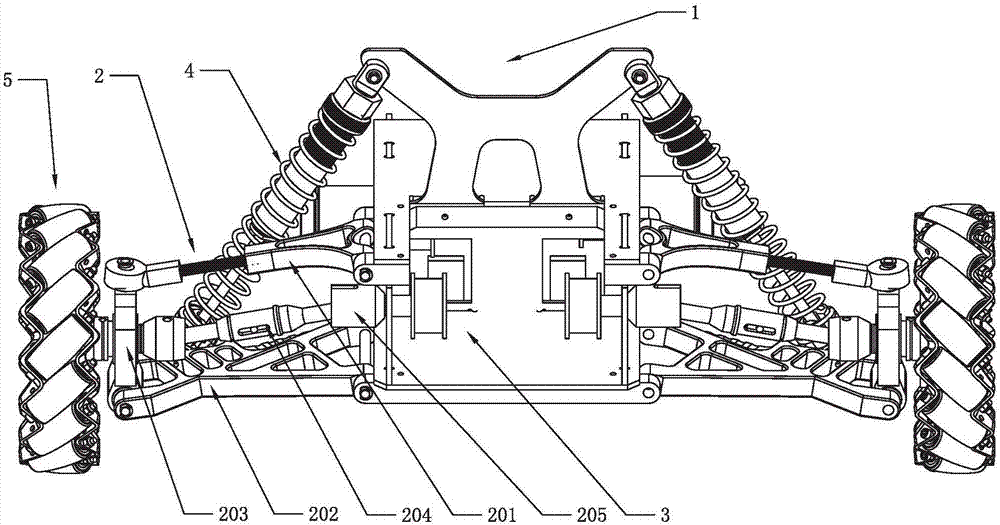

[0031] like figure 1 and figure 2 As shown, the suspension system includes a chassis 1, a connecting module 2, a power module 3, a shock absorber 4 and a Mecanum wheel 5, and the connecting module 2 includes an upper connecting arm 201 and a lower connecting arm 202 arranged in parallel, and the upper connecting arm 201 One end and one end of the lower connecting arm 202 are movably connected with the chassis 1, the other end of the upper connecting arm 201 and the other end of the lower connecting arm 202 are connected with the side connector 203, and the two ends of the shock absorber 4 are connected with the chassis 1 and the connecting module 2 respectively. It is movably connected, and the shaft end of the power module 3 is connected with the mecanum wheel 5 through the side connecting piece 203 .

[0032] The side connecting piece 203 is parallel to the corresponding surface of the chassis 1, and the side connecting piece 203 forms a parallelogram structure with the ch...

Embodiment 2

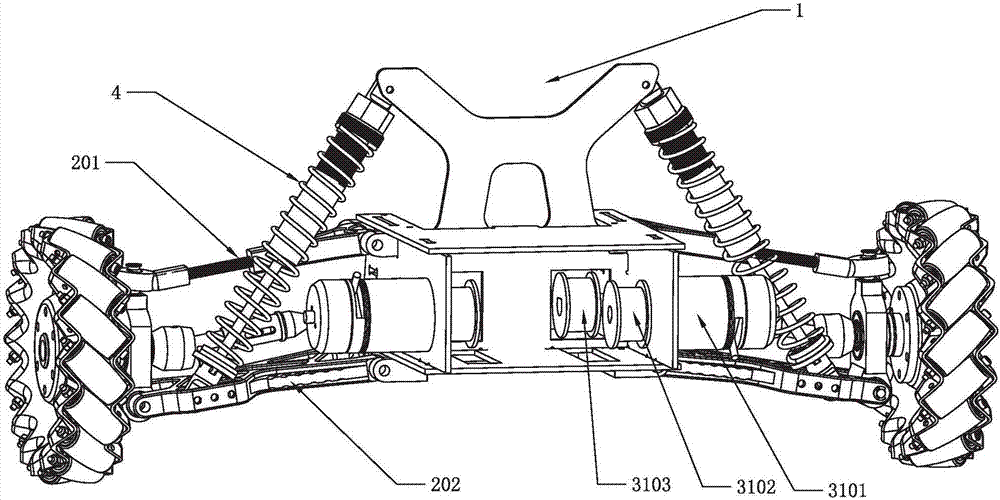

[0041] like Figure 5 and Figure 7 As shown, the suspension system and figure 1 Compared with the first embodiment shown, the difference is that the power module 3 in this embodiment includes a motor 3201, the motor 3201 passes through the chassis 1 and is connected to the driving bevel gear 3202, and the driving bevel gear 3202 and the driven bevel gear 3203 cooperate with each other , the driven bevel gear 3203 is connected with the mecanum wheel 5 through the universal joint 204 . The motor 3201 drives the driving bevel gear 3202 to rotate, and when the driving bevel gear 3202 rotates, it drives the driven bevel gear 3203 to rotate, and the driven bevel gear 3203 drives the mecanum wheel 5 to rotate through the universal joint 204 .

[0042] The driving bevel gear 3202 and the driven bevel gear 3203 are arranged perpendicular to each other, the motor 3201 drives the driving bevel gear 3202 to rotate, and the driving bevel gear 3202 and the driven bevel gear 3203 are clos...

Embodiment 3

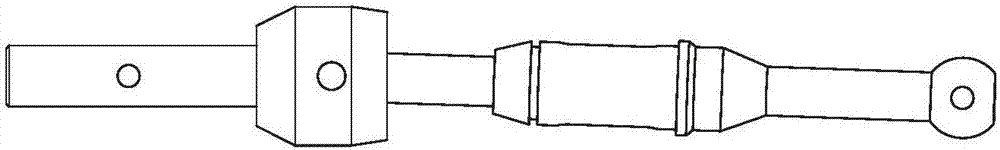

[0045] like Figure 8 and Figure 9 As shown, the suspension system and figure 1 Compared with the first shown embodiment, the difference is that one end of the shock absorber 4 in this embodiment is movably connected with the chassis 1, and the other end of the shock absorber 4 is movably connected with the side connector 203; the upper connecting arm 201 includes The first upper connecting arm 2301 and the second upper connecting arm 2302, the lower connecting arm 202 includes the first lower connecting arm 2303 and the second lower connecting arm 2304; the power module 3 includes a motor 3301, and the motor 3301 is installed on the side connecting member 203, The motor 3301 is located between the first lower connecting arm 2303 and the second lower connecting arm 2304 .

[0046] The rotating shaft of the motor 3301 passes through the side connector 203 and is connected with the mecanum wheel 5 through a coupling;

[0047]One end of the first upper connecting arm 2301 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com