Aircraft

A technology of aircraft and wire mesh, applied in the field of aircraft, can solve problems such as crashworthiness, easy deformation, fuselage damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

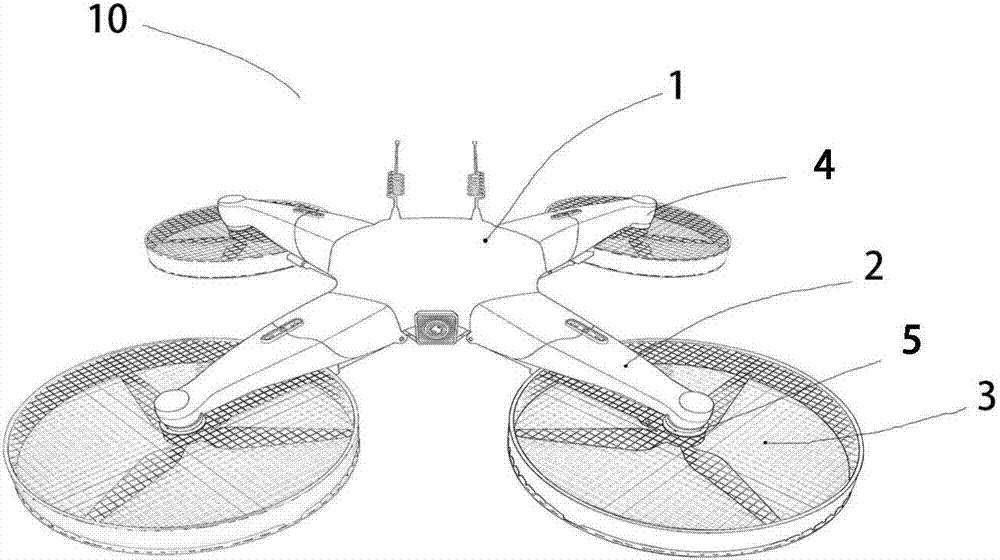

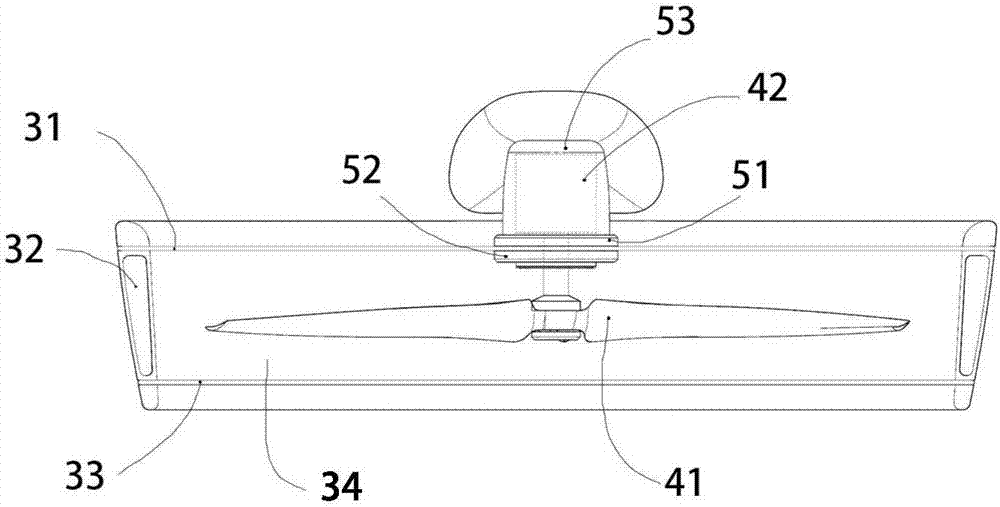

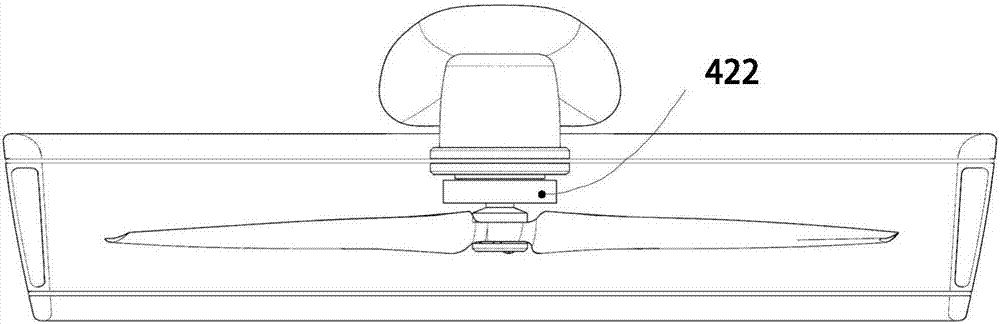

[0027] like figure 1 , figure 2 As shown, the aircraft 10 mainly includes a fuselage 1 , an arm 2 , a protective frame 3 , a power unit 4 and a mount 5 . Wherein the protective frame 3 includes the upper wire mesh 31, the side wall protective frame 32 and the lower mesh wire 33; the power unit 4 includes the driving rotor 41, the driving motor 42; the mounting seat 5 includes the mounting seat 51, the mounting plate 52 and the power mounting seat 53 . The upper wire mesh 31 , the side wall protection frame 32 and the lower wire mesh 33 are combined to form an accommodation space 34 of the power protection frame 3 ; the driving rotor 41 is placed in the accommodation space 34 and does not contact with the surroundings. The driving rotor 41 is installed on the rotating shaft of the driving motor 42, the driving motor 42 is placed in the power mounting seat 53, and the driving motor 42 and the power mounting seat 53 are installed on the mounting seat simultaneously. The upper...

no. 2 example

[0034] The difference between this embodiment and the first embodiment lies in the structure of the offline network.

[0035] like Figure 7 As shown, a support ring 8 is arranged in the middle of the lower wire mesh 332, and thread holes (not shown) for threading are processed on the side wall protection frame 322 and the support ring 9, and the pull wires are criss-crossed and run through the side wall protection frame 322 and the support ring 9 Between them, a lower wire mesh 332 is formed, and there are gasket sleeves (not shown) at the contact places between the pull wires and the holes. The seal between the gasket sleeve and the lower wire mesh 332 and the side wall protection frame 322 is completely sealed to prevent airflow from passing through the small holes on the frame form jitter. Setting the support ring 9 facilitates the installation of the aircraft drive rotor 412 .

[0036] preferred, such as Figure 8 As shown, the support ring 82 is provided with a mounti...

no. 3 example

[0039] The difference between this embodiment and the first embodiment lies in the mechanism arrangement and control of the power unit.

[0040] like Figure 9 As shown, the arms and power units are evenly distributed or symmetrically distributed on both sides of the aircraft 500 along the circumference of the aircraft 500 . The diameter of the driving rotor of the first power unit 503 is larger than the diameter of the driving rotor of the second power unit 505 , and is arranged along the general direction of the length of the fuselage 501 . The first arm 502 has a longer wheelbase than the second arm 504 and is arranged along the length of the fuselage 501 . The arm 504 is hinged to the fuselage 501 through a hinge axis, and the hinge axis is arranged along the width direction O of the arm 504 . By controlling the second arm 504, the second arm 504 can be tilted up or down to form a V-shaped structure. It can be seen that the flight maneuverability of the aircraft 500 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com