a support mechanism

A support mechanism and support seat technology, which is applied in packaging, large containers, transportation and packaging, etc., can solve the problems of large instantaneous impact force and easy impact damage of the device, so as to reduce impact damage, prolong action time and rotation angle big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

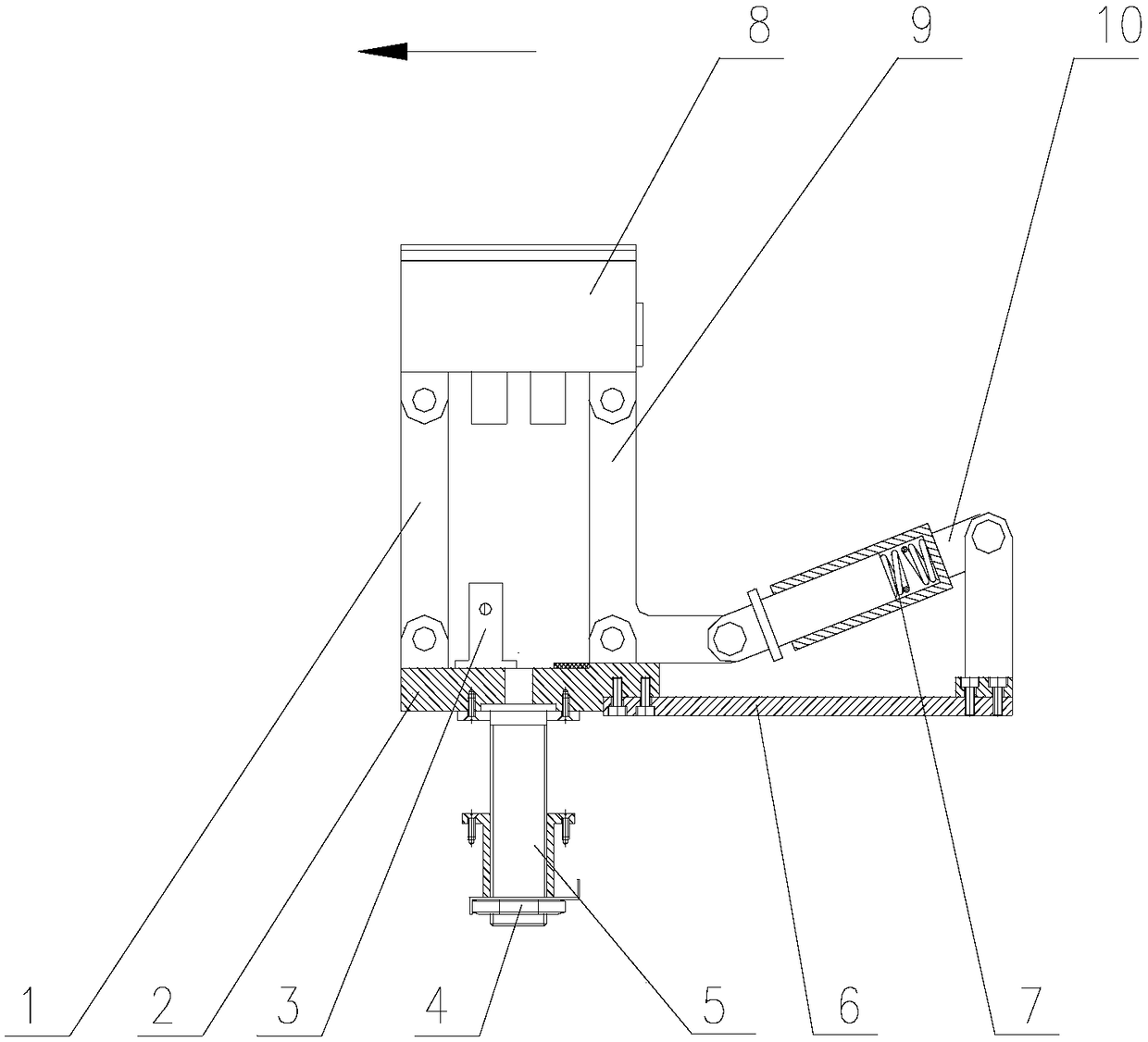

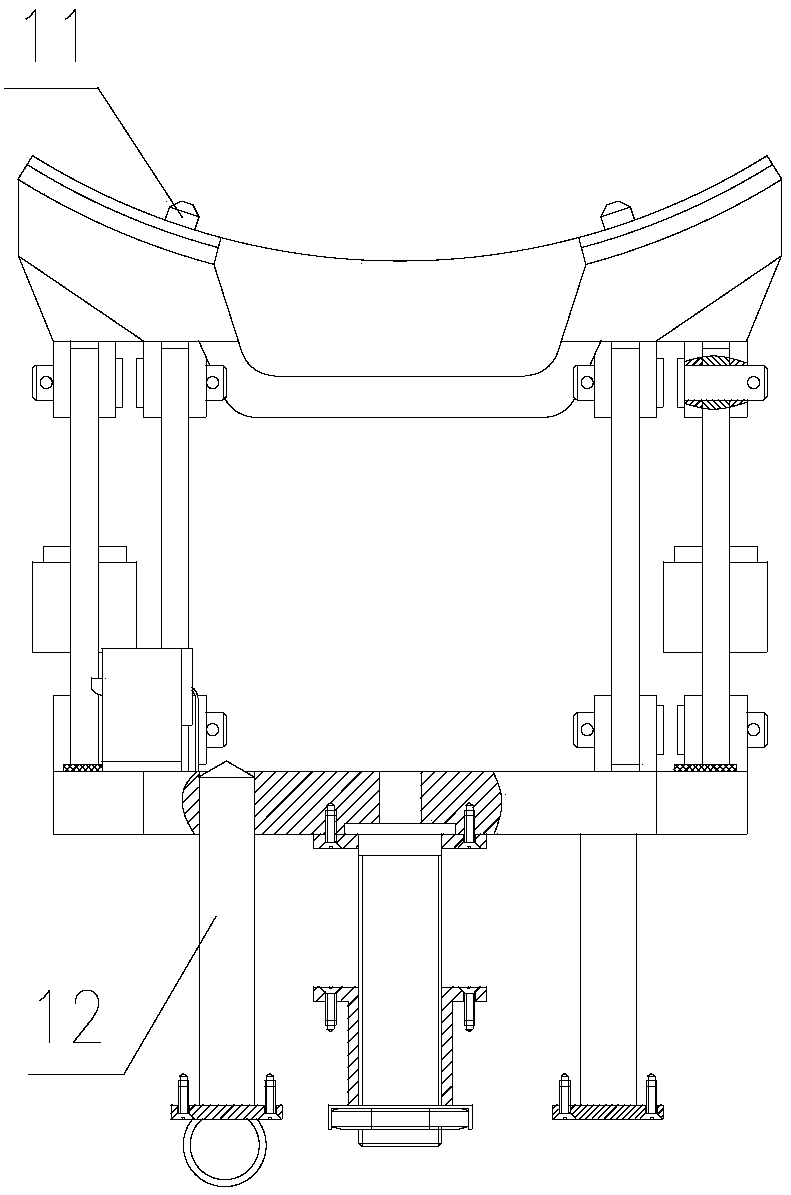

[0019] Such as figure 1 , figure 2 The supporting mechanism shown includes a front rod 1, a body 2, a connecting plate 6, a support base 8, a rear rod 9, and a vertical locking device 10; the support base 8 is arranged horizontally, and the front of the bottom of the support base 8 is rotatable A front rod 1 is fixed, and a rear rod 9 is rotatably fixed behind the bottom of the support base 8. The front rod 1 and the rear rod 9 are respectively provided with one on both sides of the support base 8, and the center lines are all aligned with the center line of the support base 8. The upper front rod 1 and the rear rod 9 do not overlap; the rear rod 9 is an L-shaped rod, the upper end of the rear rod 9 is fixed on the bottom of the support base 8, the lower end is bent outward and the outer end is fixed to the front end of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com